Introduction

In recent years, nonwoven materials have emerged as a revolutionary solution in the packaging industry, offering distinct advantages over traditional materials. The primary question that this article aims to address is, “Why are nonwoven materials ideal for packaging?” Known for their exceptional properties, nonwoven materials are increasingly being adopted across diverse industries.

Nonwoven materials are created by bonding or interlocking fibers through mechanical, thermal, or chemical processes, resulting in a versatile and durable structure. Unlike conventional woven fabrics, which are produced by weaving threads in a systematic pattern, nonwoven materials are fabricated directly from fibers, providing superior flexibility and strength. This article will explore the unique benefits, wide-ranging applications, and other essential aspects of nonwoven packaging materials, shedding light on why they are becoming the preferred choice for modern packaging solutions.

What Are Nonwoven Packaging Materials?

Nonwoven materials stand out as a versatile category of fabrics engineered by bonding fibers together through various methods, such as mechanical, thermal, or chemical processes. This advanced manufacturing technique sets nonwoven materials apart from traditional fabrics that rely on weaving or knitting. The result is a unique material characterized by its adaptability and efficiency for diverse applications.

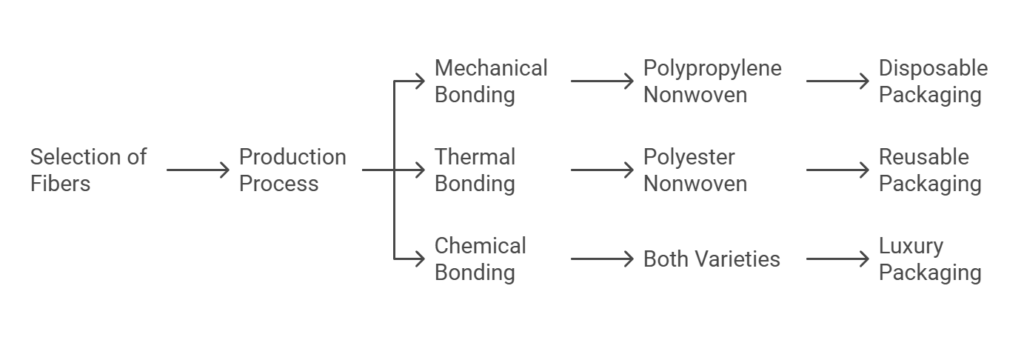

The production of nonwoven materials begins with the selection of fibers, which can be either synthetic or natural. Common fibers used include polypropylene and polyester, known for their strength, durability, and lightweight nature. These fibers are laid out in sheets, webs, or battings before being bonded using different methods. Mechanical bonding involves entangling fibers using needle punching or hydro-entangling techniques. Thermal bonding, on the other hand, employs heat to fuse fibers together, while chemical bonding uses adhesives to create a cohesive structure.

In the realm of packaging, polypropylene and polyester nonwoven materials have become indispensable. Polypropylene, for example, is often utilized in disposable packaging products due to its excellent chemical resistance, low cost, and ease of processing. Polyester, recognized for its robustness and flexibility, frequently appears in reusable packaging solutions, providing long-term durability.

Examples of nonwoven packaging materials are abundant and diverse. Grocery bags, often designed for single-use applications, are typically made from nonwoven polypropylene. Meanwhile, polyester nonwoven materials are commonly used in protective packaging, such as padded envelopes or liners for electronic goods, ensuring the safe transit and storage of sensitive items. Additionally, both polypropylene and polyester varieties find applications in luxury packaging, where they add aesthetic appeal and functional benefits to products like gift bags and specialty items.

Overall, the innovative manufacturing process and versatile properties of nonwoven materials underscore their growing prominence in the packaging industry, facilitating effective and sustainable solutions that cater to a wide range of needs. Their adaptability continues to drive advancements and innovations across numerous packaging sectors.

Advantages of Nonwoven Packaging Materials

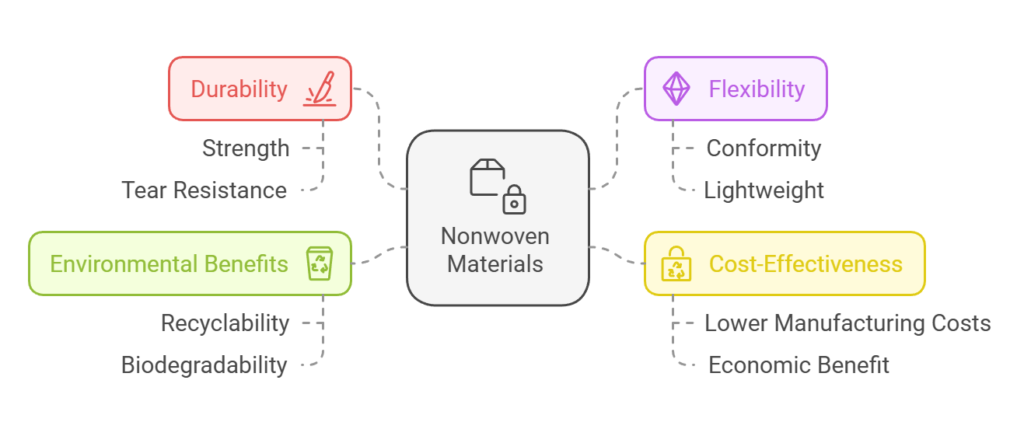

Nonwoven materials offer numerous advantages that make them particularly suitable for packaging applications. One of the most prominent benefits is their durability. These materials exhibit a high degree of strength and resistance to tearing, ensuring that the packaging can withstand significant wear and tear during transportation and handling. This longevity is critical for protecting the contents within, whether they are heavy, fragile, or sensitive items.

Flexibility is another key property of nonwoven packaging materials. They can easily conform to the shape of various products, offering a snug and secure fit. This adaptability reduces the need for additional cushioning materials, thereby minimizing packaging waste. Moreover, the lightweight nature of nonwoven materials makes them highly convenient for shipping, as they do not contribute significantly to the overall weight, hence reducing shipping costs.

In terms of cost-effectiveness, nonwoven materials often present a more affordable alternative compared to traditional packaging options like plastic and cardboard. The production process for nonwovens is generally less resource-intensive, which translates to lower manufacturing costs. This economic benefit is passed on to the end-user, making nonwoven packaging an attractive option for businesses seeking to optimize their expenditure.

From an environmental standpoint, nonwoven materials offer considerable advantages. Many nonwoven types are recyclable, which supports sustainability efforts by re-entering the production cycle rather than contributing to landfill waste. Some nonwoven materials are even biodegradable, breaking down naturally without releasing harmful pollutants into the environment. This characteristic is particularly important in reducing the overall carbon footprint of packaging.

Nonwoven packaging materials are suitable for an array of products, ranging from food and beverages to pharmaceuticals and electronics. Their ability to protect and preserve these items while offering environmental and economic benefits makes them an ideal choice for modern packaging solutions.

Applications in Various Industries

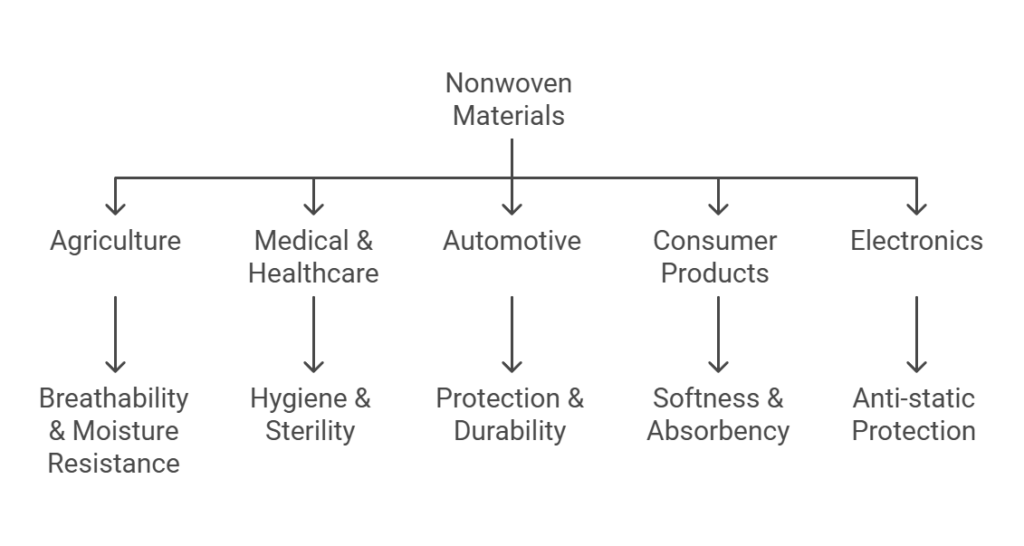

Nonwoven materials have emerged as a versatile solution for packaging across a range of industries, thanks to their unique properties such as durability, flexibility, and cost-effectiveness. These materials find extensive applications in sectors like agriculture, medical & healthcare, automotive, consumer products, and electronics, providing each field with tailored benefits and efficiencies.

In the agricultural sector, nonwoven materials are used for packaging seeds, fertilizers, and saplings. These materials offer breathability and resistance to moisture, ensuring the contents remain dry and uncontaminated. Additionally, they are environmentally friendly, often made from biodegradable fibers that support sustainable farming practices.

Within the medical & healthcare industry, nonwoven materials are critical for maintaining hygiene and sterility. They are used to package surgical instruments and medical devices, providing a barrier against microbes and contaminants. The lightweight nature of nonwovens reduces transportation costs, while their strength ensures secure containment, thereby safeguarding patient health.

The automotive industry also benefits significantly from nonwoven packaging. Components such as car parts, filters, and upholstery materials are often wrapped in nonwoven fabrics. These materials offer excellent protection against abrasions and environmental conditions during transit, preserving the integrity of the automotive parts and reducing the risk of damage.

Consumer products, ranging from personal care items to household goods, utilize nonwoven materials for both primary and secondary packaging. Items like diapers, wipes, and disposable masks often use nonwoven packaging due to its softness and absorbency. The flexibility of nonwovens ensures they can conform to various shapes and sizes, making them ideal for diverse consumer goods.

In the electronics sector, the importance of secure packaging cannot be overstated. Nonwoven materials are used to package delicate components such as circuit boards and semiconductor devices. These materials offer anti-static properties, thereby protecting electronic components from electrostatic discharge, which can cause significant damage during handling and transportation.

Overall, the widespread use of nonwoven materials across these varied industries underscores their adaptability and functional benefits. By providing specific advantages tailored to the demands of each sector, nonwoven materials have become indispensable in modern packaging solutions.

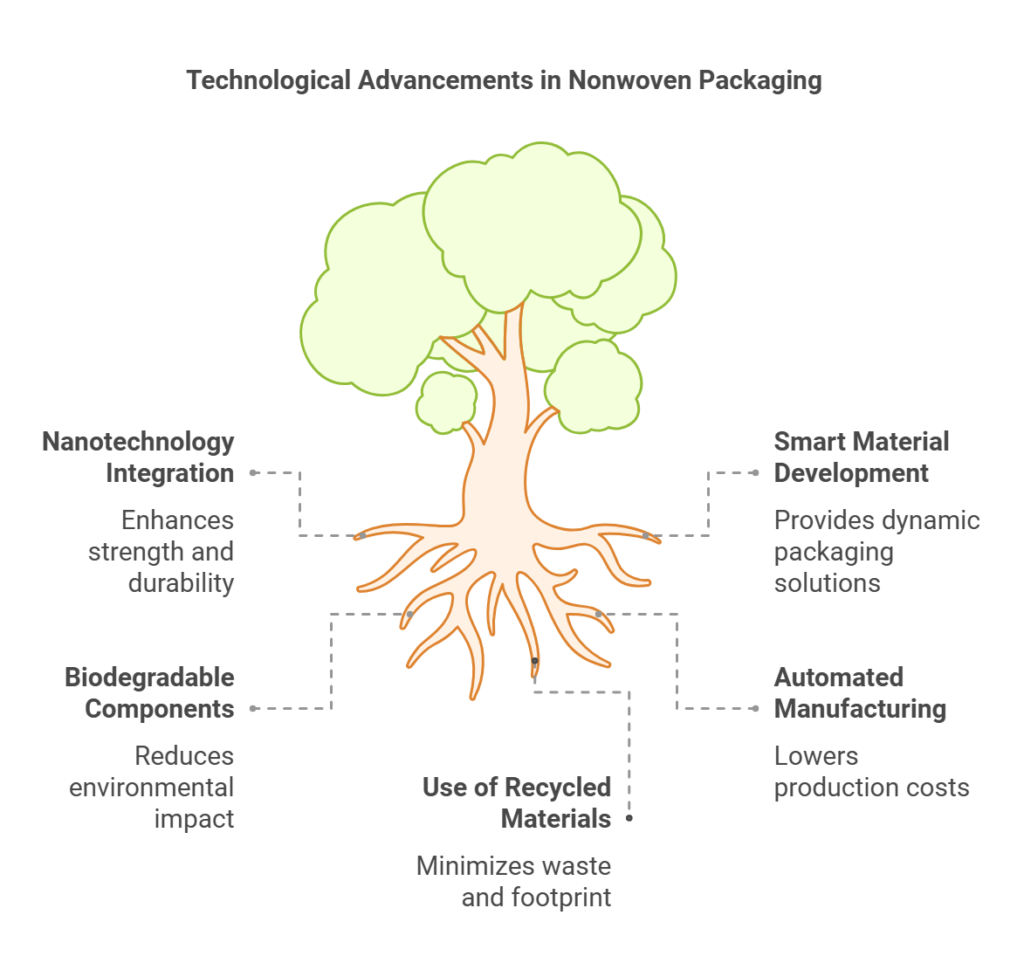

Technological Innovations

Recent years have witnessed significant technological advancements in the production and utilization of nonwoven packaging materials. These innovations have not only enhanced the performance and sustainability of nonwoven packaging but also made them more cost-efficient compared to traditional options. One notable advancement is the integration of nanotechnology, which has introduced a new realm of possibilities in the packaging industry.

Nanotechnology in nonwoven materials allows for the incorporation of nanoparticles that can enhance the strength, barrier properties, and durability of packaging. This technology also enables the creation of lightweight yet robust packaging solutions, reducing material usage and transportation costs. Furthermore, nanoparticles can impart additional functionalities such as antimicrobial properties, which are increasingly in demand in sectors like food and healthcare.

Another cutting-edge innovation is the development of smart nonwoven materials. These intelligent materials can respond to environmental stimuli, thus offering dynamic packaging solutions. For instance, smart nonwoven packaging can be designed to change color in response to temperature variations, providing a visual indicator of the product’s condition. Such functionalities are particularly beneficial for perishable goods, ensuring quality and safety throughout the supply chain.

Sustainability is another critical focus area where technological advancements are making a substantial impact. The integration of biodegradable components in nonwoven packaging materials ensures that they decompose more rapidly and safely compared to conventional plastics. Advanced manufacturing processes now allow for the use of recycled fibers and upcycled materials, significantly reducing the environmental footprint of packaging solutions.

Cost-efficiency is also being optimized through innovations in production technologies. Automated manufacturing systems and improved material blending techniques have reduced production costs, making nonwoven packaging a viable option even for large-scale applications. This combination of technological advancements is paving the way for nonwoven materials to become the standard in packaging, meeting the evolving demands for performance, sustainability, and cost-effectiveness.

Environmental Impact and Sustainability

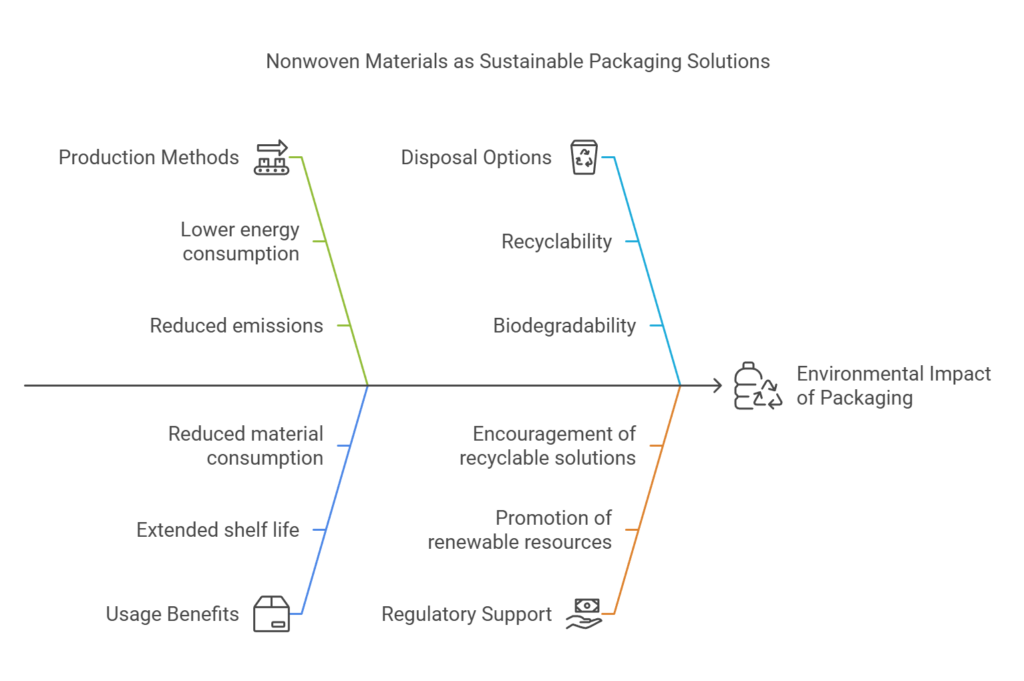

Nonwoven materials have increasingly become a focal point in discussions about sustainable packaging solutions, primarily due to their favorable environmental impact. To fully appreciate their advantages, it is crucial to examine their lifecycle, encompassing production, usage, and disposal.

During the production phase, nonwoven materials are manufactured via methods that often require fewer natural resources compared to traditional materials such as plastics or paper. The energy consumption and emissions related to their production are relatively lower, contributing to a reduced carbon footprint.

When it comes to usage, nonwoven materials stand out for their durability and versatility. Their lightweight yet robust nature means less material is needed to achieve efficient packaging, leading to a decrease in overall material consumption. Additionally, their inherent properties such as water resistance and breathability can extend the shelf life of perishable goods, reducing food waste—a significant contributor to greenhouse gas emissions.

The disposal of nonwoven materials is another critical aspect of their environmental impact. Many nonwoven materials are designed to be recyclable or biodegradable, aligning with the growing global mandate for sustainable waste management. For example, certain types of nonwoven packaging can be repurposed into new products, thereby extending their lifecycle and minimizing landfill contributions.

Comparatively, traditional packaging materials like single-use plastics have severe repercussions on the environment due to their non-biodegradable nature and the pollution associated with their extensive production and disposal processes. In stark contrast, the recyclability and degradability of nonwoven materials offer a more sustainable alternative.

Governments and organizations worldwide are increasingly recognizing the merits of nonwoven packaging. Various regulations and initiatives are in place to promote the shift towards these sustainable options. Policies encouraging the use of renewable resources and the development of recyclable packaging solutions are driving industries to adopt nonwoven materials, thereby reducing the environmental footprint of packaging globally.

In conclusion, nonwoven materials present a compelling case for sustainable packaging due to their lower environmental impact throughout their lifecycle. As regulations continue to favor sustainable approaches, nonwoven materials are poised to become more integral in the quest for eco-friendly packaging solutions.

Market Trends and Future Prospects

The market for nonwoven packaging materials has seen significant growth over recent years, bolstered by increasing consumer demand for sustainable and durable options. Market research indicates that the nonwovens industry, valued at approximately $45 billion in 2020, is projected to experience a compound annual growth rate (CAGR) of 5-7% over the next decade. This optimistic forecast is driven by the materials’ versatility, coupled with expanding applications across various sectors such as food and beverage, healthcare, and personal care products.

Key players in the market, including industry giants like DuPont, Kimberly-Clark, and Ahlstrom-Munksjö, are continuously innovating to enhance the performance characteristics of nonwoven packaging materials. These companies are focusing on developing products with improved barrier properties, increased tensile strength, and greater eco-friendly credentials. Moreover, advancements in manufacturing technologies are enabling more efficient production processes that reduce waste and lower costs.

Emerging markets, especially in regions such as Asia-Pacific and Latin America, are exhibiting robust demand for nonwoven packaging solutions. Factors such as rising disposable incomes, urbanization, and growing environmental awareness are propelling the adoption of these materials. In China and India, for instance, government regulations promoting the use of sustainable packaging are further catalyzing market growth.

Despite the promising outlook, the industry faces several challenges. The complexity and cost of recycling nonwovens pose considerable obstacles. Additionally, fluctuating raw material prices, particularly those related to oil-based polymers, can impact profit margins. However, these challenges also present opportunities for innovation. The development of biodegradable and bio-based nonwoven materials is a burgeoning area with the potential to alleviate environmental concerns and enhance the industry’s sustainability credentials.

Looking ahead, the future of nonwoven packaging materials appears bright, with continuous advancements in material science and technology. Innovations such as nanotechnology, smart packaging solutions, and enhanced recyclability are expected to drive further adoption. As global awareness surrounding sustainability intensifies, nonwoven materials are well-positioned to meet the evolving demands of the packaging industry.

Frequently Asked Questions (FAQs)

1. What are the differences between woven and nonwoven materials?

Woven materials are produced by interlacing two sets of threads at right angles, creating a durable and robust fabric. Nonwoven materials, on the other hand, are bonded together through chemical, mechanical, heat, or solvent treatment, without weaving or knitting. This results in a fabric that is generally lighter, more flexible, and versatile compared to woven materials.

2. Are nonwoven materials recyclable?

Yes, nonwoven materials are recyclable. Their recyclability depends on the polymers used in their production, most commonly polypropylene or polyester. After their initial use, they can be processed and repurposed into a variety of new products, contributing to a sustainable lifecycle.

3. How do nonwoven materials benefit the environment?

Nonwoven materials benefit the environment by promoting resource efficiency and reducing waste. Their lightweight nature means less material is required for production, minimizing the environmental footprint. Furthermore, their durability leads to longer-lasting products, reducing the frequency of replacements and associated waste. The recyclability of nonwoven materials also contributes to environmental conservation by facilitating circular economy practices.

4. What industries benefit most from nonwoven packaging?

A wide range of industries benefit from nonwoven packaging, including medical, hygiene, agricultural, and consumer goods. In the medical field, nonwoven materials are used for surgical masks, gowns, and protective wraps due to their sterile and breathable properties. For hygiene, they are prominent in disposable diapers and sanitary products. Agricultural sectors use nonwoven materials for crop protection and packaging, while consumer goods industries use them for reusable shopping bags and product packaging.

5. What are common products made with nonwoven packaging?

Common products made with nonwoven packaging include multi-use tote bags, protective covers for machinery, plant covers, disposable hygiene products, and personal protective equipment (PPE). Their adaptability allows them to be fashioned for various applications, ensuring that they meet the unique needs of different sectors and consumers.

24 Responses

What i do not realize is in fact how you are no longer actually much more wellfavored than you might be right now Youre very intelligent You recognize thus considerably in relation to this topic made me in my view believe it from numerous numerous angles Its like men and women are not fascinated until it is one thing to do with Lady gaga Your own stuffs excellent All the time handle it up

Thanks for your compliment! Glad you like our website. 😊

dodb buzz Good post! We will be linking to this particularly great post on our site. Keep up the great writing

Thank you! Glad you liked it. 😊

Masalqseen I just like the helpful information you provide in your articles

Thanks! Glad you find our articles helpful.

great post, very informative. I wonder why the other specialists of this sector don’t notice this. You should continue your writing. I’m sure, you’ve a great readers’ base already!

Thank you for your kind words! Glad you found it useful. 😊

Hi my friend! I want to say that this post is awesome, nice written and include approximately all important infos. I’d like to see more posts like this.

Thanks for your kind words! Glad you liked it. We’ll try to bring more great posts. 😊

I have learn several good stuff here. Certainly price bookmarking for revisiting. I wonder how much effort you set to create this type of magnificent informative site.

Thanks for your compliment! Glad you found our site useful. 😊

Hi, Neat post. There is a problem with your web site in internet explorer, would check this… IE still is the market leader and a big portion of people will miss your magnificent writing due to this problem.

Thank you for your feedback. We’ll look into the issue with Internet Explorer and work on getting it resolved as soon as possible.

I wanted to take a moment to commend you on the outstanding quality of your blog. Your dedication to excellence is evident in every aspect of your writing. Truly impressive!

Thank you so much for your kind and encouraging words! I’m really glad you appreciate the blog.

Hiya, I’m really glad I’ve found this info. Nowadays bloggers publish just about gossips and web and this is actually irritating. A good blog with interesting content, this is what I need. Thanks for keeping this website, I will be visiting it. Do you do newsletters? Can not find it.

Thank you so much for your kind words! We’re thrilled to hear that you appreciate our content. We strive to provide valuable and engaging information rather than just focusing on gossip.

Regarding newsletters, we do have one. You can usually find the subscription option at the bottom of our website pages. If you still can’t locate it, please let us know, and we’ll guide you through the process.

I couldn’t resist commenting

We’re glad you couldn’t hold back. Looking forward to your insights.

Some genuinely great articles on this web site, regards for contribution.

Thank you so much for your kind words! We’re thrilled that you enjoyed the articles. We’ll keep working hard to bring you more valuable content.

Very well written information. It will be helpful to anybody who utilizes it, including myself. Keep doing what you are doing – i will definitely read more posts.

Thank you so much for your kind words! We’re thrilled that you found the information useful. Looking forward to having you back for more content.