Introduction

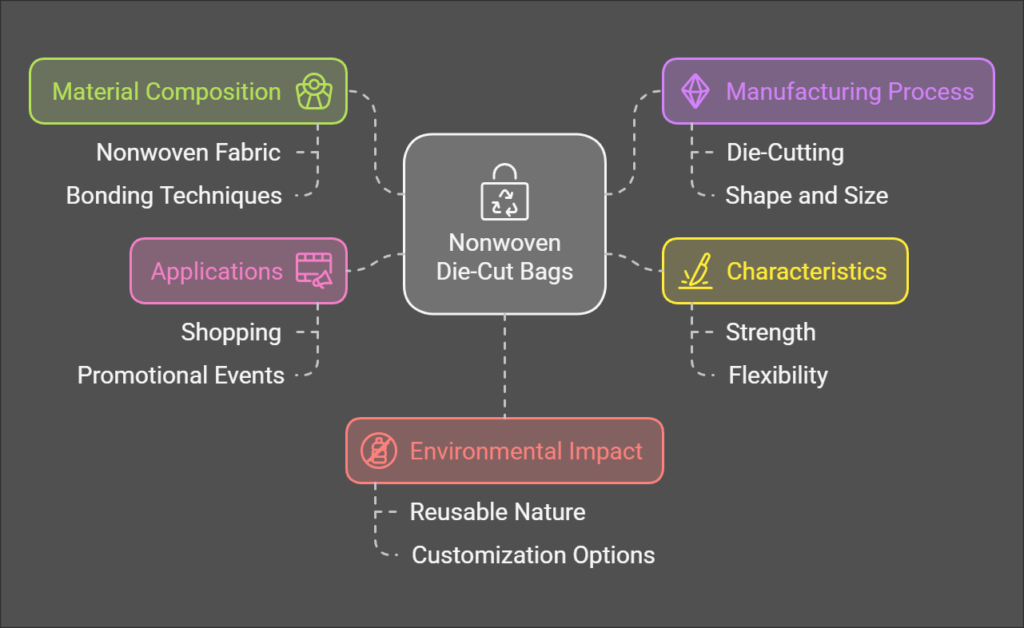

What is a Nonwoven Die-Cut Bag? This question often arises among individuals and businesses seeking sustainable and versatile packaging solutions. Nonwoven die-cut bags have gained significant attention due to their unique properties and diverse applications. These bags are crafted from nonwoven fabrics, which are engineered materials made from fibers bonded together through chemical, mechanical, heat, or solvent processes. Unlike traditional woven fabrics, nonwoven materials do not require weaving or knitting, offering a cost-effective and efficient alternative.

The term “die-cut” refers to the manufacturing technique used to shape these bags. Die-cutting involves using a specialized machine to cut the fabric into precise shapes and sizes, creating uniform bags with clean edges and standardized dimensions. This process allows for the production of various bag designs, catering to different needs and preferences. Nonwoven die-cut bags are commonly used in retail, promotional events, and packaging due to their durability, lightweight nature, and eco-friendly attributes.

In the following sections, we will delve deeper into the characteristics, advantages, and applications of nonwoven die-cut bags. By understanding these aspects, businesses and consumers can make informed decisions when selecting packaging solutions that align with their values and requirements. Whether you are looking for a sustainable alternative for shopping bags, promotional materials, or storage solutions, nonwoven die-cut bags offer a versatile and practical option worth considering.

A nonwoven die-cut bag is a type of reusable and eco-friendly bag crafted from nonwoven fabric, which is a material made from long fibers bonded together through chemical, mechanical, heat, or solvent treatment. Unlike traditional woven fabrics, nonwoven materials are not woven or knitted but are instead created by bonding fibers together, resulting in a fabric that is both durable and lightweight. The term “die-cut” refers to the precise cutting process used to shape the bag, often resulting in distinctive features such as handles or specific design patterns that enhance its functionality and aesthetic appeal.

Nonwoven die-cut bags are characterized by their strength, flexibility, and resistance to wear and tear. They are commonly used for a variety of purposes, including shopping, promotional events, and as packaging solutions. These bags are available in numerous sizes, colors, and designs, making them versatile for different applications. Due to their reusable nature, nonwoven die-cut bags serve as a sustainable alternative to single-use plastic bags, contributing to environmental conservation efforts. Additionally, they can be easily customized with logos or branding, making them an effective marketing tool for businesses.

Detailed Explanation of Nonwoven Material

Nonwoven material is a fabric-like material made from staple fibers (short) and long fibers (continuous long), bonded together by chemical, mechanical, heat, or solvent treatment. Unlike traditional woven or knitted fabrics, nonwoven materials do not require weaving or knitting, making the production process more efficient and cost-effective.

The manufacturing process of nonwoven materials typically begins with the selection of fibers, which can be natural (such as cotton or wool), synthetic (such as polyester or polypropylene), or a blend of both. These fibers are then subjected to a series of processes that include web formation, bonding, and finishing. During web formation, the fibers are laid out in a random or specific orientation to create a web structure. This web is then bonded through methods like thermal bonding (using heat), chemical bonding (using adhesives), or mechanical bonding (using needle punching or hydroentanglement).

One of the key advantages of nonwoven fabrics is their versatility. They can be engineered to have specific characteristics, such as high tensile strength, flame resistance, softness, or absorbency, depending on the requirements of their end use. This adaptability makes nonwoven materials particularly suitable for creating die-cut bags, where properties like durability, lightweight, and breathability are essential.

Another unique property of nonwoven fabrics is their ability to be produced in a wide range of thicknesses and densities. This flexibility allows manufacturers to create nonwoven die-cut bags that can cater to various applications, from lightweight shopping bags to heavy-duty packaging solutions. Furthermore, nonwoven materials are often recyclable and biodegradable, making them an environmentally friendly option.

In summary, the inherent properties of nonwoven materials, combined with their efficient manufacturing process and versatility, make them an ideal choice for producing high-quality, durable, and eco-friendly die-cut bags. Whether for retail, promotional, or industrial use, nonwoven die-cut bags offer a practical and sustainable solution.

Advantages of Nonwoven Die-Cut Bags

Nonwoven die-cut bags offer numerous advantages that make them a popular choice across various industries. One of the primary benefits is their exceptional durability. Unlike traditional plastic bags, nonwoven die-cut bags are crafted from a robust fabric-like material that can withstand substantial wear and tear. This durability ensures that the bags can be reused multiple times, making them a sustainable choice for consumers and businesses alike.

Another significant advantage of nonwoven die-cut bags is their environmental friendliness. These bags are typically made from polypropylene, a type of plastic that is both recyclable and biodegradable. This aspect aligns with the growing global emphasis on reducing plastic waste and promoting eco-friendly products. By choosing nonwoven die-cut bags, businesses can demonstrate their commitment to environmental stewardship while offering their customers a greener alternative to conventional plastic bags.

Cost-effectiveness is another notable benefit of nonwoven die-cut bags. Despite their high quality and durability, these bags are relatively inexpensive to produce. The manufacturing process involves a series of efficient, automated steps that help keep production costs low. This affordability makes nonwoven die-cut bags an attractive option for businesses looking to purchase large quantities without compromising on quality or budget.

Lastly, the versatility of nonwoven die-cut bags cannot be overstated. These bags can be customized in various shapes, sizes, and colors, making them suitable for a wide range of applications. Whether used for retail shopping, promotional events, or as packaging for products, nonwoven die-cut bags can be tailored to meet specific needs. Their sleek design and customizable features make them a practical and stylish option for both consumers and businesses.

Overall, the advantages of nonwoven die-cut bags include their durability, environmental friendliness, cost-effectiveness, and versatility. These attributes not only contribute to their growing popularity but also position them as a superior alternative to traditional plastic bags.

Common Uses of Nonwoven Die-Cut Bags

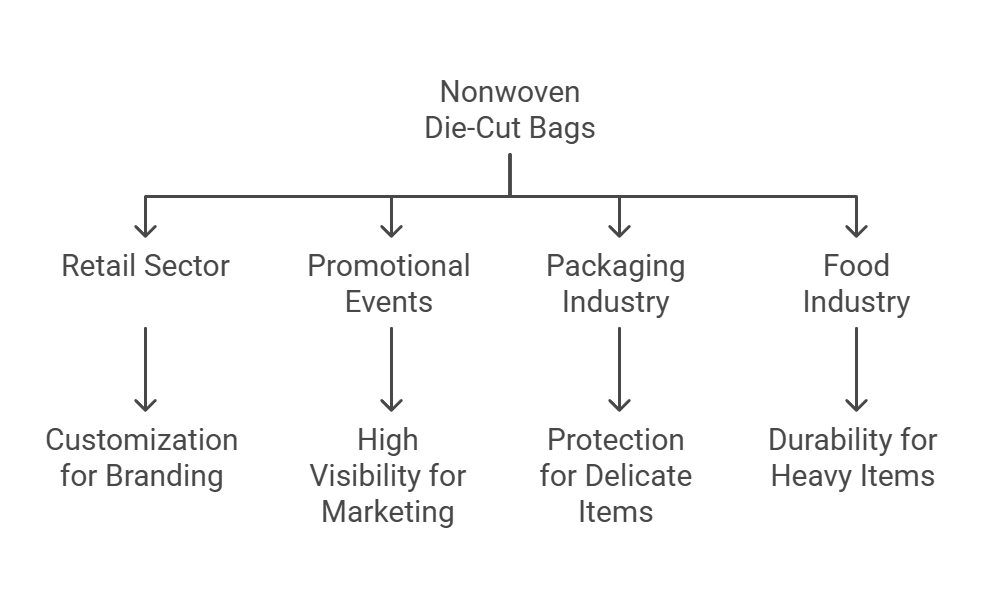

Nonwoven die-cut bags have become increasingly popular across various industries due to their versatility, durability, and eco-friendly characteristics. One of the most prevalent uses of these bags is in the retail sector. Retailers often opt for nonwoven die-cut bags as they provide a cost-effective and sustainable alternative to traditional plastic bags. These bags can be customized with the store’s branding, making them an excellent tool for marketing while also promoting environmental responsibility.

Another significant area where nonwoven die-cut bags are utilized is in promotional events. Companies and organizations frequently use these bags to distribute promotional materials, samples, and giveaways. The ability to print logos and messages on the bags ensures a high level of visibility for the brand, enhancing the effectiveness of marketing campaigns. Additionally, their sturdy construction ensures that they can hold a variety of items, making them ideal for events such as trade shows, conferences, and exhibitions.

In the packaging industry, nonwoven die-cut bags serve as a reliable option for packing products that require both protection and presentation. These bags are often used for packaging delicate items such as cosmetics, electronics, and garments. Their reusable nature also adds value for consumers, who can repurpose the bags for other uses, thereby extending the lifespan of the packaging and reducing waste.

Furthermore, nonwoven die-cut bags are increasingly being adopted by the food industry. Many restaurants and grocery stores are transitioning to these bags for packaging takeout food and groceries. The bags’ durability ensures that they can carry heavy items without tearing, and their eco-friendly nature aligns with the growing consumer demand for sustainable packaging solutions.

Overall, the versatility and eco-friendly attributes of nonwoven die-cut bags make them suitable for a wide range of applications across different industries. From retail and promotional events to packaging and food services, these bags offer a practical and sustainable solution that meets the needs of both businesses and consumers.

Design and Customization Options

Nonwoven die-cut bags offer a plethora of design and customization options that make them versatile and appealing for various applications. One of the primary customization aspects is the printing technique used. Nonwoven bags can be printed using several methods, including screen printing, heat transfer printing, and digital printing. Each technique has its unique advantages, catering to different needs and budgets. Screen printing, for instance, is ideal for bulk orders due to its cost-effectiveness, while digital printing provides higher resolution and is suitable for complex designs.

Color choices for nonwoven die-cut bags are extensive. These bags can be manufactured in virtually any color, allowing businesses to align the bag’s design with their brand identity. Whether opting for a single color or a multicolor palette, the flexibility in color selection ensures that the bags can meet specific aesthetic preferences and marketing objectives.

When it comes to size, nonwoven die-cut bags are available in a wide range of dimensions. This flexibility allows them to cater to diverse needs, from small promotional giveaways to larger shopping bags. Custom sizes can also be produced to meet specific requirements, ensuring that the bag’s dimensions are perfectly suited to its intended use.

Additional features like handles and closures add functionality and convenience to nonwoven die-cut bags. Die-cut handles are a popular choice due to their simplicity and ease of use, but other handle options such as loop handles or shoulder straps can also be incorporated. Closures, such as zippers, Velcro, or snap buttons, can be added to provide extra security for the bag’s contents. These features not only enhance the bag’s usability but also contribute to its overall aesthetic appeal.

In summary, the design and customization options for nonwoven die-cut bags are vast. With various printing techniques, color choices, sizes, and additional features, these bags offer a high level of personalization, making them an excellent choice for businesses and consumers alike.

Environmental Impact and Sustainability

In today’s rapidly evolving world, the environmental impact and sustainability of everyday items are of paramount concern. Nonwoven die-cut bags stand out as a commendable alternative to traditional bags, particularly in their environmental footprint. One of the primary advantages of nonwoven die-cut bags is their biodegradability. Unlike plastic bags, which can take centuries to decompose, nonwoven bags are designed to break down more swiftly, reducing long-term waste accumulation in landfills.

Another significant aspect of nonwoven die-cut bags is their recyclability. These bags can be recycled multiple times, curbing the need for new raw materials and lessening the strain on natural resources. This attribute not only mitigates environmental degradation but also promotes a circular economy where products are continually repurposed. Furthermore, compared to paper bags, which require deforestation and substantial water usage, nonwoven die-cut bags present a more sustainable option by utilizing less energy and raw material in their production process.

When we consider the broader spectrum of sustainability, nonwoven die-cut bags also excel in terms of durability and reusability. Their robust structure allows for repeated use, which drastically diminishes the frequency of single-use bag consumption. This reusability factor is pivotal in reducing overall waste generation and fostering a culture of environmental responsibility among consumers.

Moreover, nonwoven die-cut bags often incorporate eco-friendly materials such as recycled plastics or organic fibers, further enhancing their sustainable profile. These materials not only reduce the environmental impact during production but also ensure that the end product is less harmful when it eventually degrades. In conclusion, the shift towards nonwoven die-cut bags represents a significant stride in addressing environmental concerns, offering a more sustainable and eco-friendly alternative to conventional bagging options.

FAQs

What is the cost of nonwoven die-cut bags?

The cost of nonwoven die-cut bags can vary significantly based on factors such as size, quantity, and customization options. Generally, they are considered an economical choice, especially when ordered in bulk. Their affordability makes them a popular option for businesses seeking budget-friendly packaging solutions.

How durable are nonwoven die-cut bags?

Nonwoven die-cut bags are known for their durability. Made from polypropylene fibers, these bags possess strong tensile strength, which allows them to carry heavier loads compared to traditional plastic bags. They are also resistant to wear and tear, making them a long-lasting option for consumers and businesses alike.

Can nonwoven die-cut bags be customized?

Yes, nonwoven die-cut bags offer extensive customization options. Businesses can choose from a range of colors, sizes, and shapes. Additionally, they can be printed with logos, brand messages, or other designs, making them an excellent tool for marketing and brand promotion. Customization can help in creating a unique brand identity and improve customer recall.

Are nonwoven die-cut bags environmentally friendly?

Nonwoven die-cut bags are considered more environmentally friendly than traditional plastic bags. They are reusable and can be recycled, reducing their environmental footprint. However, it is essential to ensure proper disposal and recycling practices to maximize their eco-friendly benefits. Their reusable nature also helps in reducing single-use plastic waste.

What are the common uses of nonwoven die-cut bags?

Nonwoven die-cut bags are versatile and can be used in various applications. Common uses include retail shopping bags, promotional giveaway bags, and packaging for products. Their strength and customizability make them suitable for a wide range of industries, from fashion to groceries and trade shows.