Introduction

Nonwoven materials have emerged as a significant innovation in the field of textiles and industrial applications. Unlike traditional woven or knitted fabrics, nonwoven materials are made from fibers that are bonded together through mechanical, thermal, or chemical processes. This unique manufacturing technique allows for a wide range of functionalities, making nonwoven fabrics suitable for various applications, including medical, automotive, and packaging industries.

One of the most compelling aspects of nonwoven materials is their contribution to sustainability. As consumers and industries alike become increasingly aware of environmental concerns, the demand for sustainable alternatives to traditional materials has surged. Nonwoven materials offer numerous sustainability advantages that can significantly impact ecological footprints. Their ability to be engineered for specific purposes allows for reduced waste in manufacturing processes. Moreover, many nonwoven fabrics are made from recycled or biodegradable materials, aligning with environmentally friendly practices.

The diversification of nonwoven material applications not only enhances their utility but also broadens the scope for sustainable innovations. For instance, using nonwoven materials in packaging can diminish the reliance on single-use plastics, promoting better waste management practices. Additionally, nonwoven fabrics in the healthcare sector can improve hygiene and safety while being designed for single-use, thereby reducing reprocessing challenges often associated with reusable textiles.

As this discussion unfolds, we will explore the various sustainability advantages presented by the diversification of nonwoven materials. Each application and its corresponding environmental impact will illustrate how this innovation stands as a significant player in the pursuit of sustainable practices across different sectors. By understanding these advantages, stakeholders can make informed decisions that benefit both their enterprises and the planet.

Understanding Nonwoven Materials

Nonwoven materials represent a unique category of fabrics that are created through various processes that do not involve weaving or knitting. Unlike traditional textiles, nonwoven fabrics are produced by bonding fibers together using chemical, mechanical, or thermal techniques. This innovative method results in materials that exhibit a variety of characteristics tailored for specific applications.

The composition of nonwoven materials generally includes synthetic fibers such as polyester, polypropylene, or polyethylene, as well as natural fibers like cotton and cellulose. The choice of fibers significantly influences the properties of the final product, including durability, absorbency, and softness. One of the principal advantages of nonwoven fabrics is their versatility, as they can be engineered to meet specific performance criteria, making them suitable for a wide array of uses, from medical supplies and personal protective equipment to household items and geotextiles.

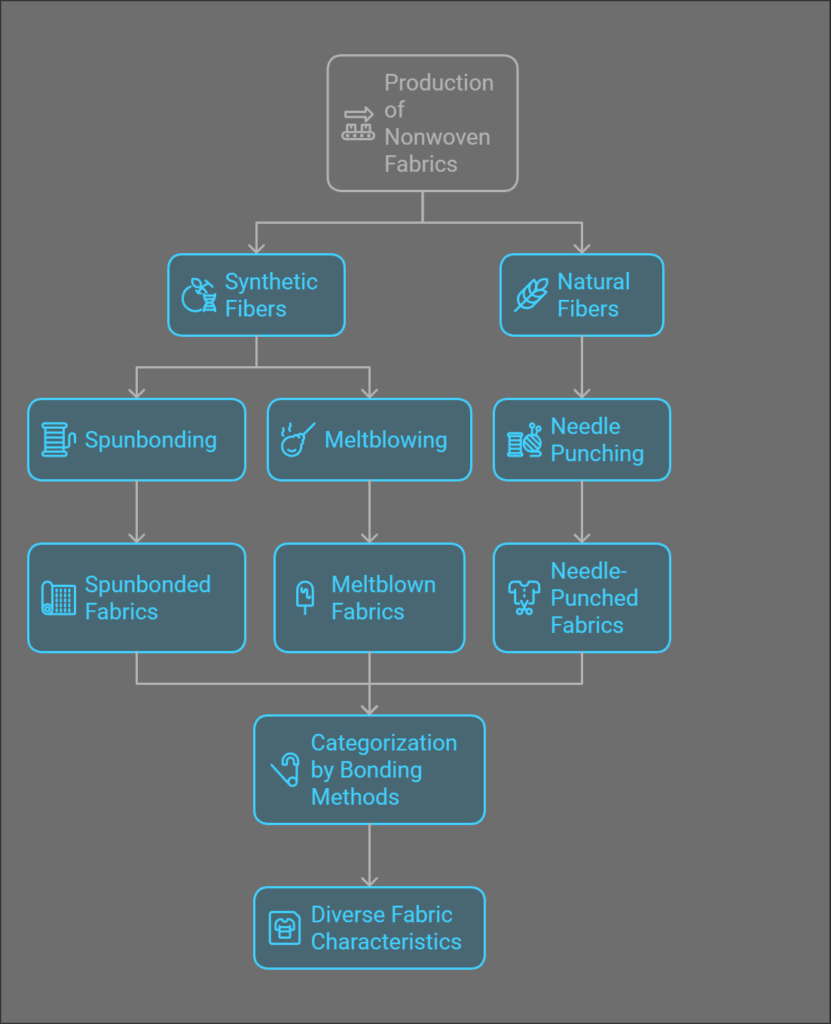

Manufacturing nonwoven materials typically involves several processes, such as spunbonding, meltblowing, and needle punching. In spunbonding, continuous filament fibers are laid down in a web and bonded through a thermal process, resulting in a strong and lightweight fabric. Meltblowing involves extruding thermoplastic polymer melts to create fine fibers, ideal for applications requiring high filtration efficiency. Needle punching, on the other hand, uses barbed needles to entangle fibers, producing a dense textile that is beneficial for filter media and insulation.

Different types of nonwoven fabrics can be categorized by their bonding methods and fiber types, which allows for a wide range of characteristics such as hydrophobicity, flame resistance, and breathability. This diversity not only enhances their functionality in various settings but also plays a crucial role in environmental considerations, particularly regarding the sustainability advantages discussed later in this blog. Understanding these foundational elements of nonwoven materials is essential for comprehending their broader implications in our efforts towards sustainability.

The Importance of Diversification in Nonwoven Applications

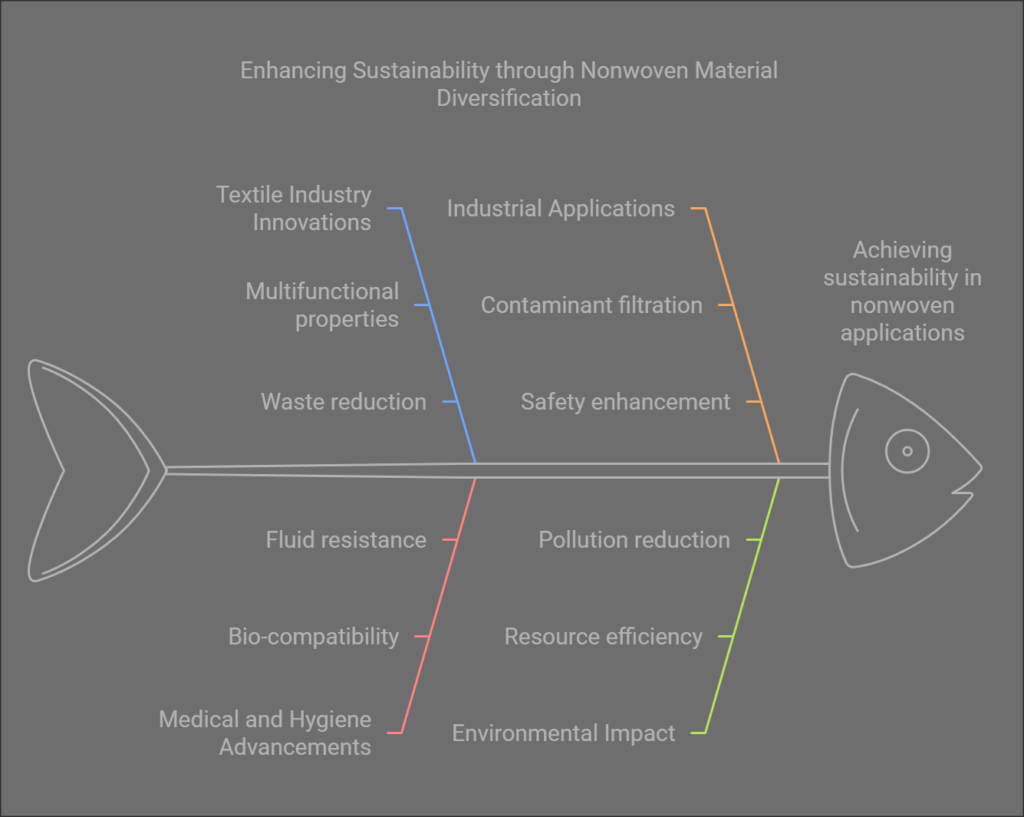

Nonwoven materials are experiencing a significant transformation, primarily due to their diverse applications across multiple sectors. These materials, composed of biodegradable fibers or polymers that are bonded together, offer enhanced functionality, making them an essential component in various industries such as textiles, medical, hygiene, and industrial applications. The diversification of nonwoven materials can lead to increased sustainability and operational efficiency, ultimately contributing to environmental protection.

In the textile industry, nonwoven fabrics provide lightweight and durable alternatives that are not only cost-effective but also offer multifunctionality. For example, they can be used to produce clothing, upholstery, and filter media. The versatility of nonwoven textiles allows manufacturers to tailor their properties, such as breathability, moisture wicking, and UV resistance, catering to the specific needs of consumers while reducing waste and resource consumption.

The medical and hygiene sectors have seen a significant improvement through the adoption of nonwoven materials. These materials are typically engineered to meet stringent hygiene and safety standards, making them suitable for applications such as surgical gowns, masks, and absorbent pads. The ability to design nonwoven products that enhance bio-compatibility and fluid resistance has led to improved patient outcomes and overall public health. By diversifying applications in these critical areas, the reliance on single-use plastics can be reduced, promoting a more sustainable healthcare approach.

In industrial applications, nonwoven materials are utilized for filtration systems, insulation, and protective apparel. Their ability to effectively filter out contaminants and provide essential safety features showcases how diversification can lead to enhanced performance and reduced environmental impact. As industries continue to adopt sustainable practices, the role of nonwoven materials becomes increasingly pivotal, driving innovation and efficiency across various sectors.

Ultimately, the importance of diversifying nonwoven applications cannot be overstated. By leveraging their multifunctional properties, industries can adopt more sustainable practices while meeting consumer demands. This approach not only ensures longevity for these materials but also promotes environmental stewardship across various sectors.

Sustainability Benefits of Nonwoven Fabric Diversification

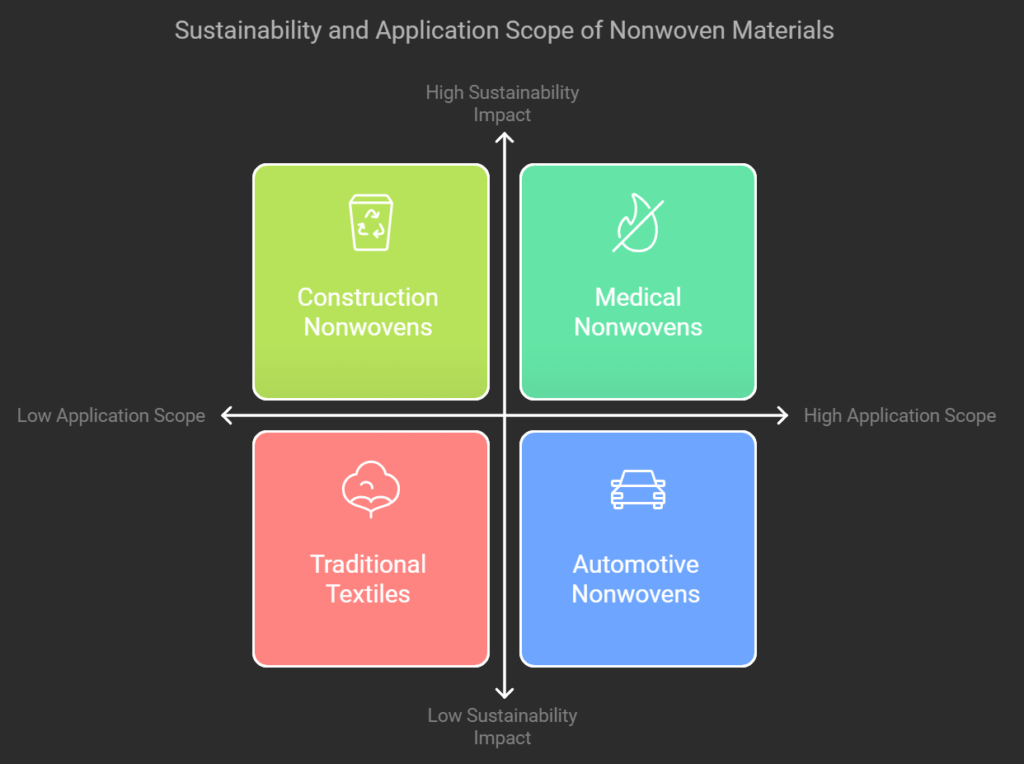

Nonwoven fabrics are gaining attention in the sustainability sector due to their diverse range of applications and innovative manufacturing processes. One of the primary sustainability advantages of nonwoven material diversification is the potential for reduced resource consumption. Traditional textiles often require extensive water usage, chemical treatments, and energy-intensive processes. However, nonwoven materials can be produced with a significantly reduced environmental footprint, as they often utilize fewer raw materials and energy compared to conventional textile production methods.

The versatility of nonwoven fabrics allows them to be used in various industries, from healthcare and construction to automotive and packaging. This widespread applicability means that manufacturers can tailor their production processes to meet specific sustainability goals. For example, by selecting bio-based or recycled fibers in their nonwoven fabric production, companies can contribute to a circular economy. Utilizing recycled materials not only minimizes waste but also alleviates the pressure on natural resources, ensuring a more sustainable approach to manufacturing.

Another critical aspect of nonwoven fabric diversification is its impact on waste management efficiency. Nonwoven materials are often designed for single-use applications, which can lead to unique challenges in waste disposal. However, advancements in the industry have led to the development of biodegradable nonwoven alternatives. These products decompose naturally in the environment, significantly reducing the burden on landfills and minimizing environmental pollution. Additionally, layered nonwoven structures can be engineered to enhance recyclability, allowing for repurposing at the end of their life cycle.

Overall, the sustainability benefits associated with diversified nonwoven materials are profound. By reducing resource consumption, enabling better waste management practices, and promoting recyclable and biodegradable options, nonwoven fabrics represent a promising avenue for enhancing environmental sustainability in various applications. Such advancements will play a pivotal role in addressing the pressing challenges of resource scarcity and environmental degradation as industries continue to evolve.

Case Studies: Nonwoven Materials in Sustainable Practices

Nonwoven materials have rapidly gained traction across various industries, demonstrating their versatility and sustainability. One notable example is in the medical field, where nonwoven fabrics are utilized for surgical gowns and masks. These materials offer a combination of lightweight comfort and biological barrier properties, ensuring that healthcare providers are protected while also being disposable. Companies such as Medline Industries have embraced eco-friendly manufacturing processes by producing nonwoven products that are not only effective but also biodegradable, thereby minimizing environmental impact.

Another example is in the construction industry, where nonwoven geotextiles play a crucial role in sustainability. Used for soil stabilization and erosion control, these materials help in preserving landscapes while promoting plant growth. For instance, the use of such fabrics in green roofing initiatives has become increasingly popular. Research by the National Institute of Standards and Technology indicates that these nonwoven materials can enhance water retention in green roofs, leading to a significant reduction in urban heat islands and improved stormwater management. This offers a sustainable solution while addressing environmental challenges associated with urbanization.

The automotive sector also showcases innovative uses of nonwoven materials. Manufacturers have adopted nonwoven composites for interior components, such as headliners and sound insulation. These products not only reduce vehicle weight, enhancing fuel efficiency and lowering emissions, but also promote the use of recycled materials in their production. Companies like Toyota have implemented nonwoven fabric components that are derived from recycled plastics, showcasing a commitment to sustainability and environmental stewardship within the automotive industry.

These case studies illustrate the potential of nonwoven materials in advancing sustainable practices across multiple sectors. With their diverse applications, nonwoven fabrics contribute significantly to environmental conservation while providing efficient and effective solutions tailored to specific industry needs. The integration of these materials demonstrates that sustainable innovations can align with economic viability, paving the way for a greener future.

Challenges in Implementing Nonwoven Sustainability Practices

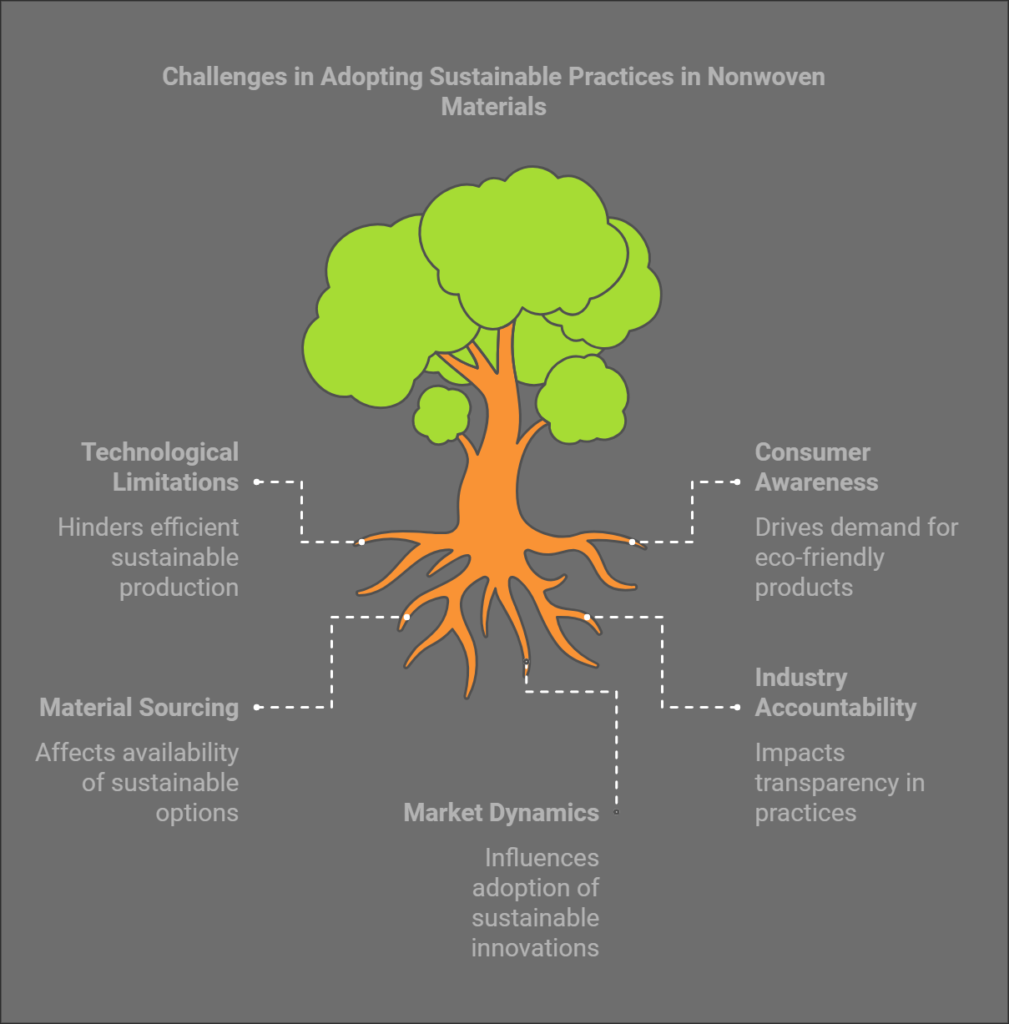

The adoption of sustainable nonwoven materials presents numerous challenges that industries must navigate to achieve diversification in their practices. One significant barrier is the economic considerations associated with transitioning to sustainable nonwoven products. Many companies face higher initial costs in sourcing environmentally friendly materials. This economic hurdle can deter investment, especially in industries where profit margins are already tight. Organizations might also find it difficult to justify the switch to sustainable nonwovens when traditional materials are more readily available and cheaper, thus inhibiting broader adoption.

Technological limitations also play a critical role in the implementation of sustainable practices related to nonwoven materials. Many existing production processes are optimized for traditional fabrics, and adapting these to accommodate sustainable alternatives can require substantial redesigns. Additionally, there may be a lack of available technology specifically tailored for the creation of sustainable nonwoven materials. This gap can slow innovation and deter companies from making necessary changes. Without the right technologies, industries may struggle to meet both the quality and sustainability standards expected from nonwoven products.

Moreover, regulatory frameworks can add another layer of complexity. Industries must navigate a landscape of varying regulations and standards regarding sustainability, which can differ significantly from one region to another. This inconsistency can complicate the process of sourcing and manufacturing nonwoven materials, making it challenging for companies to comply with all necessary regulations while still striving for sustainability. Furthermore, as consumer awareness of sustainability continues to rise, companies may find themselves in a perpetual state of adaptation, striving to align their offerings with evolving consumer expectations and regulatory requirements.

Future Trends in Nonwoven Material Sustainability

As we delve into the future of nonwoven materials, it is essential to recognize the anticipated trends that will shape their sustainability landscape. The nonwoven fabric industry is experiencing a significant shift towards sustainable practices, driven by technological advancements, innovations in materials, and changing consumer preferences towards environmentally-friendly products. This evolution is pivotal in meeting the growing demand for sustainable solutions across various sectors, including hygiene, medical, and construction.

One promising trend is the increasing integration of bio-based materials in nonwoven fabric production. As industries strive to reduce their reliance on fossil fuels, manufacturers are exploring sources such as plant fibers and biodegradable polymers. This pivot not only enhances the sustainability of nonwoven products but also aligns with global efforts to mitigate climate change. Enhanced performance characteristics of these innovative materials can lead to wider applications while maintaining ecological integrity.

The role of technology in advancing nonwoven material sustainability cannot be overstated. Emerging technologies, such as advanced polymers and spinning techniques, are set to improve the efficiency of manufacturing processes. Enhanced techniques like melt-blown and spunbond methods can facilitate the production of lightweight, durable, and recyclable nonwoven materials. These advancements not only promise lower energy consumption during production but also contribute to the lifecycle sustainability of the final products.

Moreover, consumer awareness and preferences are rapidly evolving, influencing market dynamics. As consumers increasingly prioritize sustainability, manufacturers are encouraged to adopt eco-friendly practices. This trend has prompted the nonwoven fabric industry to enhance transparency in sourcing and production processes, thereby fostering a culture of accountability. By aligning with consumer values, the industry can drive demand for sustainably-produced nonwoven materials, reinforcing a shift towards a circular economy.

In conclusion, the future of nonwoven material sustainability is poised for transformative developments through innovative technologies, higher material diversity, and a heightened consumer focus on sustainability. Embracing these trends will not only benefit the industry but also contribute to a more sustainable planet.

FAQs About Nonwoven Sustainability Advantages

As the demand for sustainable materials increases, many people are turning their attention to nonwoven materials. Understanding their sustainability advantages can help make informed decisions. Here are frequently asked questions regarding this topic:

What are nonwoven materials? Nonwoven materials are fabrics made from bonding or interlocking fibers rather than being woven. This method allows for production efficiency and versatility in various applications, including medical products, automotive interiors, and hygiene items.

Are nonwoven materials recyclable? While not all nonwoven materials are recyclable, many types can be repurposed or recycled, depending on their composition. Additionally, some manufacturers are using recycled materials to create nonwoven products, making them more environmentally friendly.

How do nonwoven materials contribute to sustainability? Nonwoven materials offer several sustainability advantages, including reduced waste, improved energy efficiency during production, and longer lifespans in applications. Their versatile nature enables them to be used in multi-functional products, which can minimize the need for additional materials.

Do nonwoven materials pose health risks? Nonwoven textiles can be produced from various fibers, raising questions about potential health risks. However, many nonwoven materials are made from safe, non-toxic substances and are designed for specific applications, ensuring that they meet stringent safety standards.

What industries benefit from nonwoven sustainability? Nonwoven materials find use in numerous industries, including healthcare, agriculture, construction, and consumer goods. Their sustainable properties make them an attractive choice for companies looking to reduce their environmental footprint while maintaining performance standards.

Awareness of the sustainability advantages of nonwoven materials is crucial for both consumers and manufacturers. By considering these frequently asked questions, individuals can better understand how nonwoven products fit into a sustainable future.

Conclusion

In reviewing the sustainability advantages of nonwoven material diversification, several critical points have emerged. Firstly, the variety offered by nonwoven materials plays a vital role in addressing diverse needs across different industries, ultimately contributing to more sustainable practices. By catering to specific requirements, these materials enable manufacturers to select the most optimal products for their applications, thus minimizing waste and enhancing efficiency in production processes.

Moreover, diversification in nonwoven materials fosters innovation, leading to the development of environmentally-friendly alternatives. This innovative spirit catalyzes the movement away from traditional fabrics and fibers, which often carry significant environmental burdens. By incorporating varied nonwoven materials, industries can adopt more sustainable practices that support resource conservation and reduce ecological impact.

Furthermore, the flexibility inherent in nonwoven material production facilitates easier recycling and repurposing, aligning with circular economy principles. As more companies recognize the importance of sustainability, the adoption of diversified nonwoven materials will likely increase, as it provides a pathway toward reducing carbon footprints and promoting responsible consumption. This is particularly significant in sectors such as healthcare, automotive, and construction, where evolving consumer expectations and regulatory pressures necessitate sustainable solutions.

In summary, the diversification of nonwoven materials not only enhances operational sustainability but also lays the groundwork for long-term environmental benefits. As industries increasingly prioritize sustainability, embracing the advantages of nonwoven material diversification will become essential. This approach not only addresses current ecological challenges but also equips industries with the tools necessary for future resilience and sustainability, fostering a positive impact on the environment as a whole.

8 Responses

NY weekly Awesome! Its genuinely remarkable post, I have got much clear idea regarding from this post . NY weekly

Thank you! I’m glad you found the post helpful and clear.

Thank you for the good writeup It in fact was a amusement account it Look advanced to far added agreeable from you However how could we communicate

Glad you enjoyed it! You can reach out to us via the contact form on our website, http://www.non – woven.com. We look forward to communicating with you.

obviously like your website but you need to test the spelling on quite a few of your posts Several of them are rife with spelling problems and I to find it very troublesome to inform the reality on the other hand Ill certainly come back again

Thank you so much for bringing this to our attention! We sincerely apologize for the spelling issues. Our team will immediately review and correct all the posts. We strive for perfection and your feedback is invaluable in helping us achieve that. Looking forward to serving you better on your next visit.

Hi i think that i saw you visited my web site thus i came to Return the favore Im attempting to find things to enhance my siteI suppose its ok to use a few of your ideas

Thank you so much for your comment and for thinking our ideas could be helpful to enhance your website! We’re glad you found value in our content. If you have any questions or need further insights, feel free to reach out. We’re always happy to share more.