Introduction

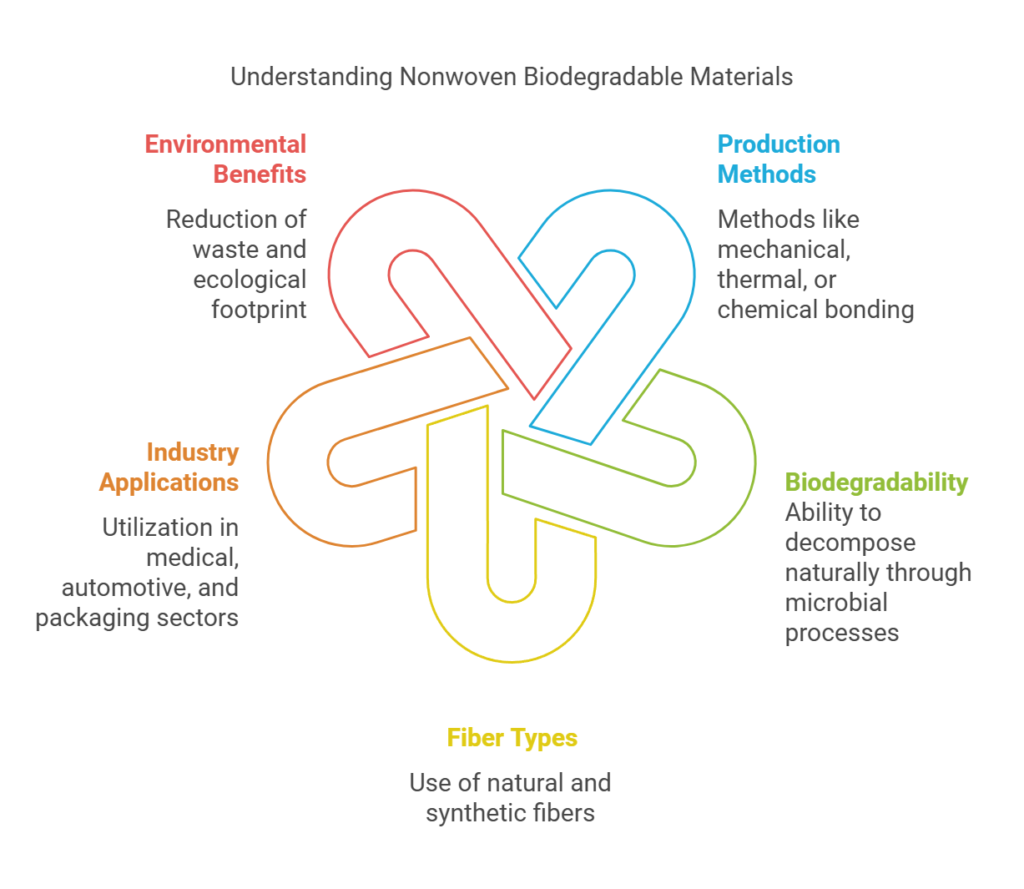

Nonwoven biodegradable materials are an innovative class of fabrics distinguished by their dual characteristics: nonwoven production and biodegradability. These materials do not undergo the traditional weaving or knitting processes. Instead, they involve methods such as mechanical, thermal, or chemical bonding to create a fabric from individual fibers. This unique fabrication process contributes to certain beneficial properties, such as high absorbency, strength, and filtration efficiency, which are extensively utilized across various industries including medical, automotive, and packaging sectors.

The biodegradability aspect of these materials is equally significant. It pertains to their inherent ability to decompose naturally through microbial processes under specific environmental conditions. This aspect is facilitated by the composition of the fibers, which can be either natural, such as cotton or jute, or synthetic, like polylactic acid (PLA) and polyhydroxyalkanoate (PHA). The strategic combination of nonwoven technology and biodegradable fibers ensures that these materials do not persist in the environment long after their intended use, thereby reducing waste and minimizing ecological footprint.

To elaborate, natural fibers utilized in nonwoven biodegradable materials inherently harbor properties conducive to environmental safety. For instance, natural fibers are biodegradable and often renewable, contributing to soil fertility upon decomposition. Conversely, synthetic biodegradable fibers are engineered to degrade efficiently, mimicking natural degradation processes, thus closing the loop on sustainable lifecycle management. The integration of these fibers in nonwoven structures ensures the materials can undergo controlled breakdown, primarily facilitated by microorganisms, resulting in non-toxic byproducts.

Ultimately, nonwoven biodegradable materials represent a forward-thinking material solution aimed at addressing environmental concerns associated with traditional non-biodegradable textiles. By leveraging the advances in fiber technology and eco-friendly design, these materials provide functional applications across industries while promoting sustainability and environmental stewardship.

The Manufacturing Process of Nonwoven Biodegradable Materials

The manufacturing process of nonwoven biodegradable materials is a meticulous sequence involving various natural and biodegradable synthetic fibers. Common raw materials include plant-based fibers like bamboo, cotton, and hemp, and biodegradable synthetic fibers such as polylactic acid (PLA). The transformation of these materials into nonwoven fabrics involves several critical stages, each contributing to the material’s final properties and environmental sustainability.

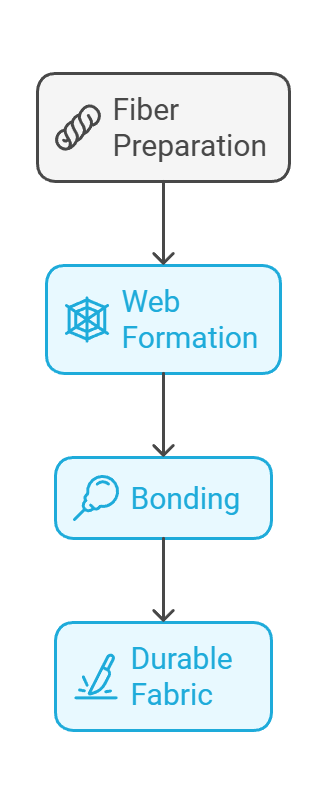

The process begins with fiber preparation, where raw fibers are cleaned, sorted, and optionally blended to achieve desired properties. In the case of plant-based fibers, this stage involves separating and refining the fibers to ensure uniformity and quality. For PLA and other synthetic fibers, this step might include melting and extrusion processes to form fibrous filaments.

Following fiber preparation, the next phase is web formation. The prepared fibers are laid out into a web using various techniques such as carding, air laying, or wet laying. Carding typically involves disentangling and orienting the fibers, creating a consistent layer. Air laying employs an air stream to distribute and align the fibers, whereas wet laying suspends fibers in water to form a mat upon drying. Each method influences the web’s properties, affecting the final fabric’s texture, strength, and versatility.

The third crucial step is bonding, where the web structure is consolidated to produce a coherent, durable fabric. Bonding methods can be divided into thermal, mechanical, and chemical categories. Thermal bonding uses heat to fuse fibers together, often employed with PLA, which melts and binds without damaging biodegradability. Mechanical bonding, such as needle punching or hydroentangling, physically entangles fibers without additional materials. Chemical bonding involves applying adhesives or binders to hold the fibers together, ensuring the end product remains biodegradable.

This comprehensive manufacturing process not only ensures the production of high-quality nonwoven biodegradable materials but also emphasizes their environmental benefits. Through careful selection of raw materials and precise control of each manufacturing stage, these materials offer a sustainable alternative to traditional nonwoven fabrics.

Applications and Uses

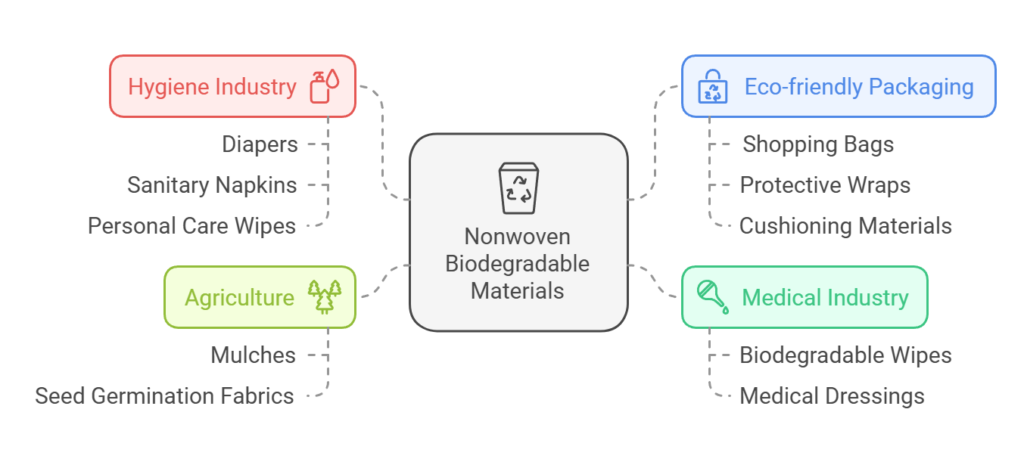

Nonwoven biodegradable materials find diverse applications across various industries due to their sustainability advantages and functional benefits. In the medical industry, these materials are utilized extensively in products such as biodegradable wipes and medical dressings. These items are essential for maintaining hygiene and health standards, while also ensuring minimal environmental impact. The use of biodegradable materials ensures that waste produced in medical facilities is significantly reduced, contributing to a cleaner environment.

The hygiene industry also benefits greatly from nonwoven biodegradable materials. Products such as diapers, sanitary napkins, and personal care wipes use these materials to provide consumers with effective hygiene solutions that do not contribute to long-term waste accumulation. The materials decompose naturally, leaving less burden on waste management systems and landfills.

In agriculture, biodegradable nonwoven materials are commonly used in the form of mulches and seed germination fabrics. Agricultural mulches made from these materials help in weed control, soil moisture retention, and enhanced crop yields. Once their purpose is fulfilled, they degrade naturally into the soil, eliminating the need for removal and disposal, thus saving labor and costs while supporting sustainable farming practices.

Eco-friendly packaging is another significant application area. Nonwoven biodegradable materials are used to create packaging solutions that are not only environmentally friendly but also effective in protecting goods during transport and storage. Examples include shopping bags, protective wraps, and cushioning materials. These packaging options are highly sought after by consumers and businesses aiming to reduce their carbon footprint and embrace sustainable practices.

The use of nonwoven biodegradable materials provides substantial benefits including reduced environmental impact, improved product performance, and cost efficiency. As industries continue to shift towards sustainable practices, the adoption of these materials is likely to increase, fostering a greener and more responsible approach to manufacturing and consumption.

Environmental Impact and Sustainability

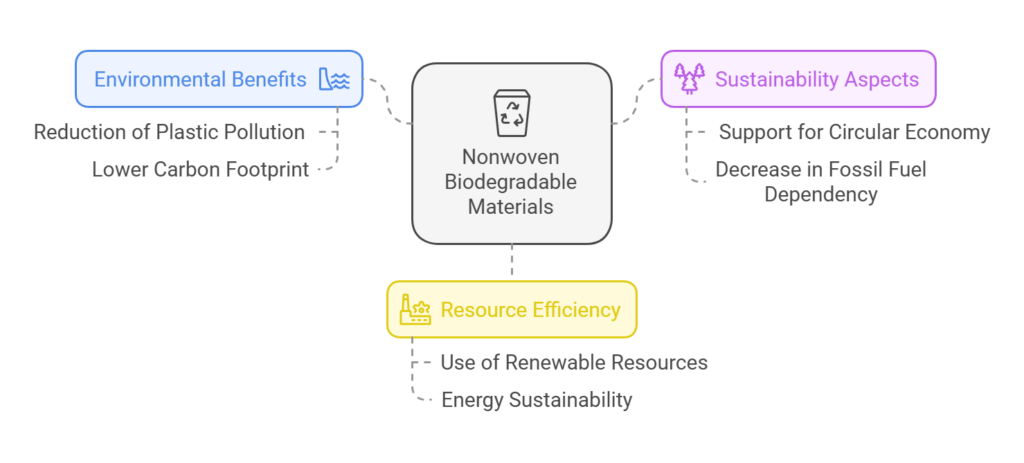

Nonwoven biodegradable materials offer significant environmental benefits compared to traditional nonwoven fabrics made from non-biodegradable plastics. One of the primary advantages is their ability to reduce plastic pollution. Traditional nonwoven fabrics, often derived from plastics like polypropylene, contribute to environmental degradation due to their persistence in ecosystems. Nonwoven biodegradable materials, on the other hand, decompose more readily, thereby mitigating the accumulation of plastic waste in landfills and oceans.

The production of nonwoven biodegradable materials also typically involves a lower carbon footprint. The process of creating these materials often requires less energy and generates fewer greenhouse gas emissions compared to the production of synthetic nonwoven fabrics. This reduction in carbon emissions is crucial in combatting climate change and promoting environmental sustainability. Moreover, the use of plant-based or natural fibers in biodegradable materials further enhances their eco-friendliness, as these fibers can be sourced from renewable resources.

Nonwoven biodegradable materials contribute to a circular economy by enabling the recycling and composting of products at the end of their life cycle. Unlike traditional nonwoven plastics that persist for centuries, biodegradable materials break down into natural substances that can enrich the soil and support new plant growth. This cyclical process reduces waste and promotes resource efficiency, aligning with sustainable development goals.

Additionally, the shift towards nonwoven biodegradable materials decreases dependency on fossil fuels. Most synthetic nonwoven fabrics are petroleum-based, whereas biodegradable alternatives are often derived from natural, renewable resources such as cornstarch, bamboo, or plant-based polymers. By reducing reliance on fossil fuels, these biodegradable materials help to conserve limited natural resources and promote energy sustainability.

Overall, the adoption of nonwoven biodegradable materials plays a vital role in promoting sustainable practices within the textile industry. By leveraging renewable resources, lowering carbon emissions, and supporting a circular economy, these materials provide a promising pathway towards a more sustainable future.

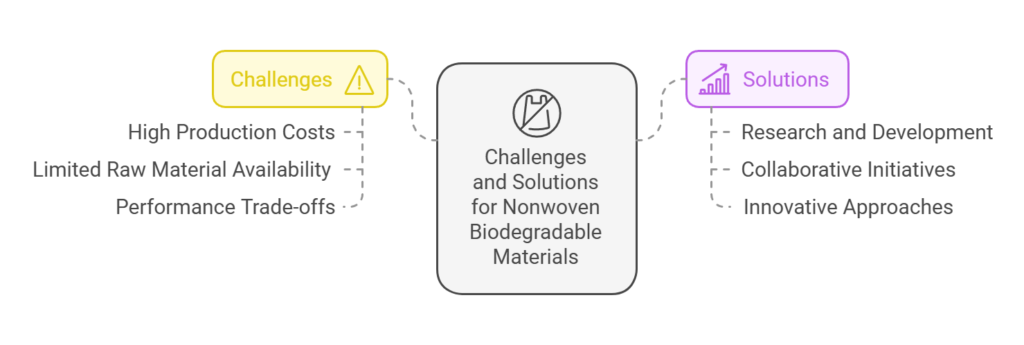

Challenges and Limitations

Nonwoven biodegradable materials, while promising for sustainable development, face several challenges and limitations. One of the most significant hurdles is the higher production cost compared to conventional nonwoven materials. This cost disparity primarily arises from the synthesis and processing techniques required for biodegradable alternatives, which are often more complex and resource-intensive. As a result, industries may be hesitant to adopt these eco-friendly options due to economic constraints.

Additionally, the limited availability of raw materials also poses a challenge for the scalability of nonwoven biodegradable materials. Biodegradable polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are derived from renewable resources like corn starch and microbial bacteria. However, the production of these raw materials is still relatively small scale and cannot meet the growing global demand. This scarcity restricts widespread application and integration into industrial processes.

Moreover, there are potential performance trade-offs when using nonwoven biodegradable materials. While these materials are designed to decompose under specific environmental conditions, their mechanical properties might not always match those of traditional non-biodegradable counterparts. Attributes such as tensile strength, durability, and resistance to external factors can be compromised, limiting their functional effectiveness in certain applications.

Ongoing research and development efforts are crucial to addressing these challenges. Scientists and material engineers are exploring innovative approaches to enhance the cost-effectiveness of production processes, improve the availability of raw materials, and refine the material properties to meet performance demands. For instance, advancements in bio-based feedstocks and biotechnological innovations are paving the way for more efficient and sustainable solutions. Collaborative initiatives between academic institutions, industry stakeholders, and government bodies are also instrumental in accelerating these developments and promoting the adoption of nonwoven biodegradable materials.

The journey towards integrating nonwoven biodegradable materials into mainstream use is complex, but with continued research and collaboration, the barriers can be progressively minimized, rendering these materials more viable and effective for a sustainable future.

Future Trends and Innovations

As the demand for sustainable solutions continues to grow, the nonwoven biodegradable materials industry is poised for significant advancements. One of the most notable future trends is the development of cutting-edge fiber technology. Researchers are focusing on creating fibers with enhanced biodegradability, strength, and versatility to meet an array of application needs. Innovations in fiber technology include the utilization of nanotechnology to produce fibers that degrade more efficiently in natural environments.

In addition to technological advancements, there is a burgeoning interest in sourcing raw materials from renewable, sustainable sources. Companies are exploring the use of agricultural byproducts, such as hemp, flax, and bamboo, to produce nonwoven fabrics. These materials not only reduce reliance on fossil fuels but also promote agricultural sustainability. The use of biopolymers derived from plants, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), is also gaining traction due to their biodegradable properties and lower environmental impact.

Improved manufacturing processes are another critical area of innovation. The development of more environmentally friendly production methods is essential to minimize the ecological footprint of nonwoven biodegradable materials. Techniques such as water-based processes and solvent-free production methods are being refined to ensure that the manufacturing of these materials aligns with sustainability goals. Furthermore, advancements in recycling and composting technologies are extending the lifecycle of nonwoven products, allowing for greater resource efficiency.

There is a growing interest in compostable and biobased nonwovens as consumers and industries alike seek eco-friendly alternatives. Compostable nonwovens are designed to break down into natural elements in composting conditions, leaving no harmful residues. This trend is particularly significant in the context of single-use products, where the environmental burden of disposal is a major concern. Biobased nonwovens, made from renewable resources, offer a sustainable option that reduces dependency on non-renewable materials. As these innovations and trends gain momentum, they are expected to shape the future landscape of the nonwoven biodegradable materials industry, driving it towards greater sustainability and environmental responsibility.

Frequently Asked Questions (FAQs)

What are the main types of biodegradable fibers used?

There are several types of biodegradable fibers utilized in nonwoven materials. The most commonly used include polylactic acid (PLA), cellulose-based fibers like cotton and rayon, and other plant-based fibers such as jute and hemp. These fibers are chosen for their ability to break down naturally and hold certain desirable properties such as strength and flexibility.

How long do biodegradable nonwovens take to decompose?

The decomposition time for biodegradable nonwovens greatly varies depending on the specific material and environmental conditions. On average, these materials take between a few months to several years to fully degrade. Factors impacting decomposition time include the presence of microorganisms, exposure to water and sunlight, and ambient temperature. For instance, PLA nonwovens can decompose in around 6 to 12 months under industrial composting conditions.

Are there any certifications for biodegradable materials?

Yes, there are several certifications that validate the biodegradability of materials. Certifications such as the Biodegradable Products Institute (BPI) certification, the European EN 13432 standard, and the ASTM D6400 standard are commonly used. These certifications ensure that materials meet specific criteria for biodegradability and compostability, providing assurance to manufacturers and consumers about the environmentally friendly nature of the product.

What are the cost implications of switching to biodegradable nonwovens?

The cost implications of transitioning to biodegradable nonwovens can vary widely. Generally, biodegradable materials tend to be more expensive than their non-biodegradable counterparts due to factors like raw material sourcing, production processes, and economies of scale. However, costs may decrease over time as production scales up and technological advancements are made. Additionally, organizations may benefit from long-term cost savings through improved sustainability practices, potential regulatory incentives, and bolstering their environmental reputation among consumers.

12 Responses

Techno rozen I do not even understand how I ended up here, but I assumed this publish used to be great

Thank you for your support and recognition – it means a great deal to me. Together, let us continue on this journey of sharing knowledge and wisdom for the betterment of all.

Internet Chicks Great information shared.. really enjoyed reading this post thank you author for sharing this post .. appreciated

Thank you for your kind words! I’m thrilled to hear you enjoyed the post. Your appreciation means a lot. Stay tuned for more content!

Hi my loved one I wish to say that this post is amazing nice written and include approximately all vital infos Id like to peer more posts like this

Thanks for your compliment! Glad you liked the post. We’ll try to bring more valuable content like this.

I have been browsing online more than three hours today yet I never found any interesting article like yours It is pretty worth enough for me In my view if all website owners and bloggers made good content as you did the internet will be a lot more useful than ever before

Thank you for your kind words! Glad you enjoyed the article. 😊

Pink Withney For the reason that the admin of this site is working, no uncertainty very quickly it will be renowned, due to its quality contents.

Thanks for your compliment! We will keep providing quality contents.

Do you make a biodegradable non-woven or woven fabric? I need a high strength and high water permeability.

Thank you for your comment. Yes, we do produce biodegradable non – woven fabric that meet high strength and high water permeability requirements. For further inquiries, you can reach us via Whatsapp at +86 13599755808.