Introduction

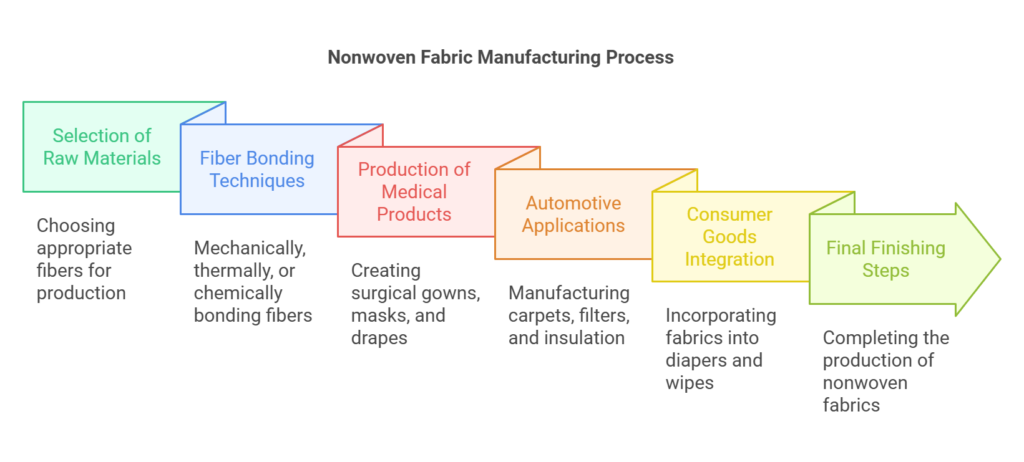

The nonwoven manufacturing process is a fascinating and complex method that involves creating fabric-like materials without the traditional techniques of weaving or knitting. Unlike woven fabrics, which are produced by interlacing threads, nonwoven materials are made by bonding or entangling fibers through various means such as mechanical, thermal, or chemical processes. This unique method of production has paved the way for diverse applications across multiple industries.

Nonwoven fabrics are integral to a wide range of sectors, including medical, automotive, and consumer goods industries. In the medical field, nonwoven materials are used to produce disposable surgical gowns, masks, and drapes, offering essential benefits in terms of hygiene and infection control. The automotive industry leverages nonwoven fabrics in the production of carpets, filters, and insulation materials, enhancing vehicle comfort and performance. Additionally, consumer goods such as diapers, wipes, and personal care products frequently incorporate nonwoven fabrics due to their absorbency, softness, and strength.

Understanding the nonwoven manufacturing process is crucial for appreciating the versatility and functionality of these materials. By delving into the intricacies of this process, we can better grasp the innovative techniques that enable the creation of high-performance nonwoven fabrics. This article will explore the various stages involved in the nonwoven manufacturing process, providing a comprehensive overview of how these remarkable materials are produced. From the selection of raw materials to the final finishing steps, we will answer the key question: How is it done?

What is Nonwoven Fabric?

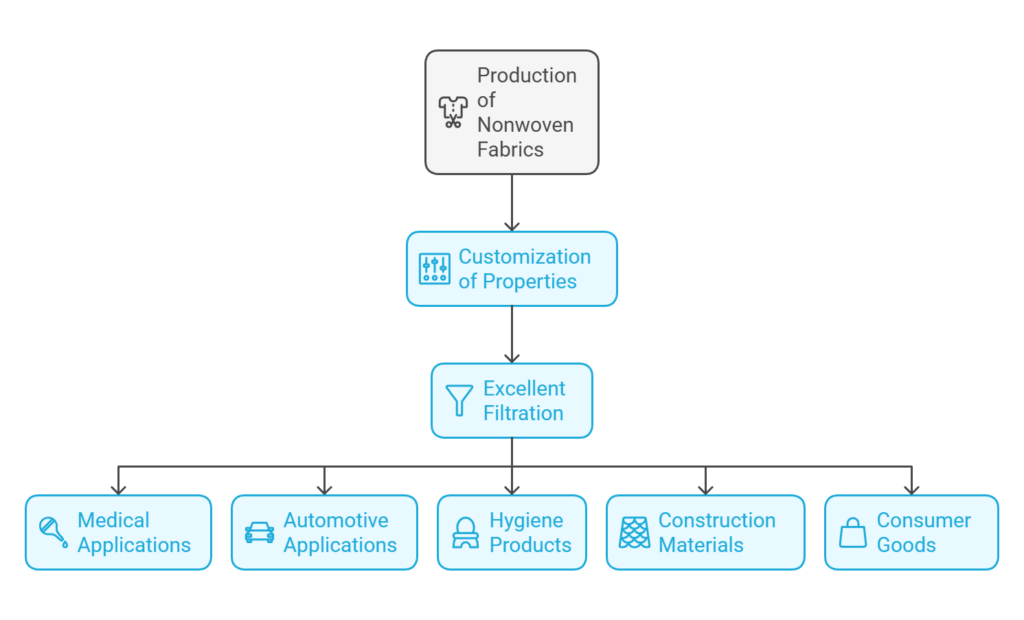

Nonwoven fabric is a versatile material created from long fibers that are bonded together through various methods, such as chemical, mechanical, heat, or solvent treatment. Unlike traditional fabrics, which necessitate weaving or knitting processes, nonwoven fabrics are manufactured by entangling fibers together, leading to a distinct set of properties and applications.

The unique production process of nonwoven fabrics results in materials that can be tailored to exhibit specific characteristics. For instance, nonwoven fabrics can be engineered to be lightweight, durable, absorbent, or resistant to various elements like fire, water, and chemicals. This adaptability is a key factor in their widespread use across multiple industries.

One of the primary properties of nonwoven fabrics is their ability to provide excellent filtration. This makes them ideal for use in medical and healthcare settings, such as surgical masks, gowns, and drapes. The automotive industry also benefits from nonwoven fabrics, utilizing them in components like filters, insulation, and upholstery.

Apart from these applications, nonwoven fabrics are extensively used in the hygiene sector. Products like baby diapers, adult incontinence products, and feminine hygiene products rely on the absorbent and soft nature of nonwoven materials. Additionally, the construction industry employs nonwoven fabrics in roofing materials, house wraps, and geotextiles, showcasing their structural integrity and durability.

In the realm of consumer goods, nonwoven fabrics find their place in items such as wipes, tote bags, and even in fashion accessories. The flexibility in design and function allows manufacturers to innovate and create products that meet specific consumer needs.

Overall, the significance of nonwoven fabrics lies in their diverse applications and the ability to customize their properties to fit various requirements. As technology and manufacturing methods continue to advance, the potential uses and benefits of nonwoven fabrics are expected to expand, further solidifying their role in modern industry and everyday life.

Raw Materials Used in Nonwoven Manufacturing

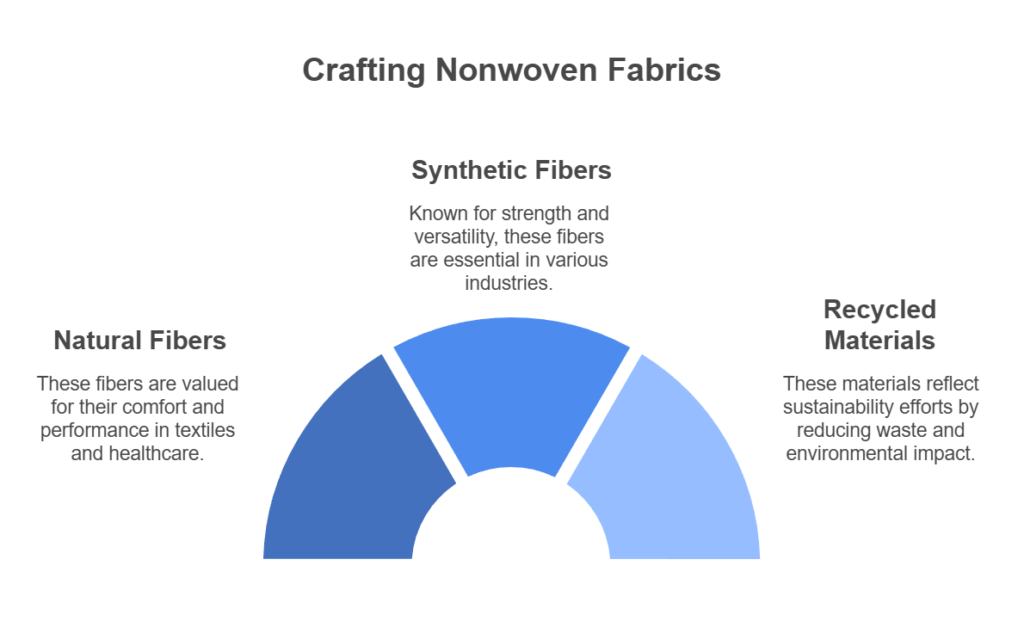

The production of nonwoven fabrics integrates a diverse range of raw materials, each contributing uniquely to the fabric’s properties and applications. Natural fibers, synthetic fibers, and recycled materials constitute the primary categories utilized in nonwoven manufacturing.

Natural fibers such as cotton and wool are frequently employed owing to their inherent properties. Cotton, sourced from the cotton plant, is valued for its softness, breathability, and hypoallergenic qualities. Wool, derived from sheep, offers excellent insulation and moisture-wicking capabilities. These fibers enhance the comfort and performance of nonwoven fabrics, making them suitable for applications in the textile and healthcare industries.

Synthetic fibers, including polyester and polypropylene, are equally significant in nonwoven production. Polyester, a polymer derived from petroleum, is renowned for its strength, durability, and resistance to shrinking and stretching. Polypropylene, another petroleum-based polymer, is lightweight, cost-effective, and exhibits excellent chemical resistance. These fibers are integral to producing robust and versatile nonwoven materials used in automotive, construction, and hygiene products.

Recycled materials are increasingly being incorporated into nonwoven manufacturing, reflecting a growing emphasis on sustainability. Recycled polyester, derived from post-consumer plastic bottles, retains many of the desirable properties of virgin polyester while reducing environmental impact. Similarly, recycled cotton, reclaimed from textile waste, helps in mitigating landfill waste and conserving resources. The integration of recycled materials not only supports environmental conservation but also aligns with consumer demand for eco-friendly products.

The choice of raw materials in nonwoven manufacturing is pivotal in determining the final product’s characteristics, such as strength, absorbency, and texture. By leveraging the unique attributes of natural, synthetic, and recycled fibers, manufacturers can produce nonwoven fabrics tailored to specific applications and performance requirements. This versatility underscores the importance of raw material selection in the nonwoven manufacturing process.

Nonwoven Fabric Production Techniques

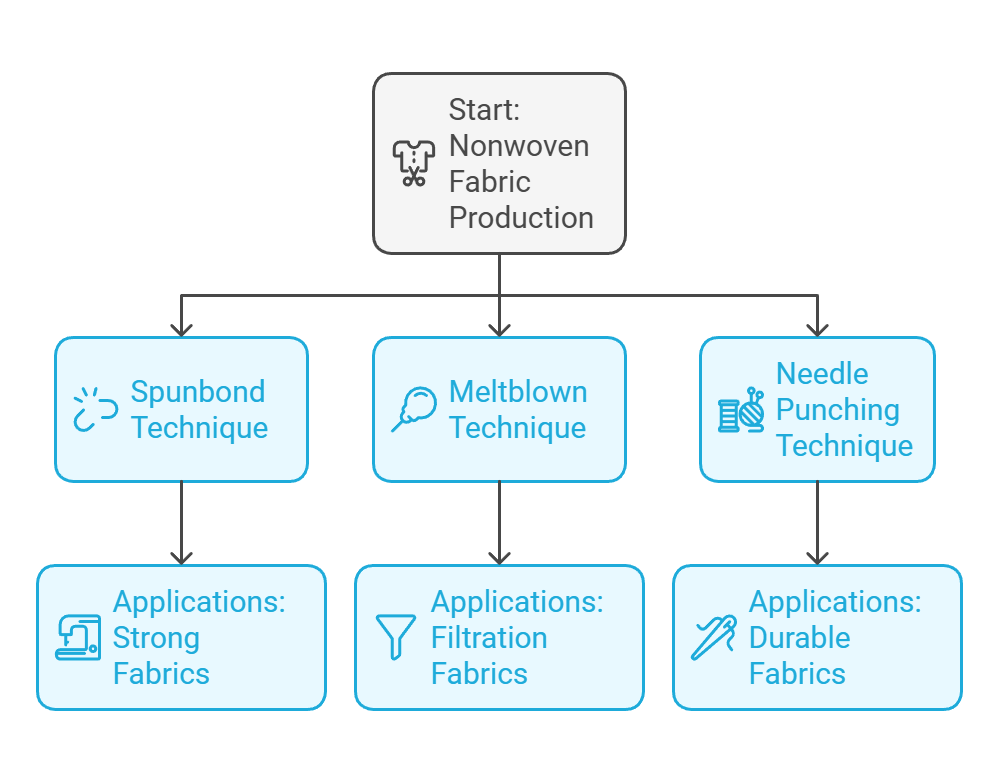

Nonwoven fabric production encompasses a variety of methods, each tailored to create fabrics with specific properties and applications. Among the most prevalent techniques are spunbond, meltblown, and needle punching, each of which utilizes distinct processes to transform raw materials into finished products.

The spunbond technique involves extruding thermoplastic polymers through spinnerets to form continuous filaments. These filaments are then laid randomly onto a moving conveyor belt to create a web. This web is subsequently bonded together through heat, pressure, or chemical means. The spunbond method is renowned for producing strong, durable fabrics that find widespread use in applications such as agricultural coverings, geotextiles, and disposable hygiene products.

Meltblown technology, on the other hand, generates finer fibers compared to the spunbond process. In this method, molten polymers are extruded through nozzles with high-speed blowing gas, which attenuates the polymer streams into microfibers. These microfibers are collected on a conveyor belt to form a web that is bonded through thermal or chemical processes. Meltblown fabrics are characterized by their excellent filtration properties, making them ideal for use in medical masks, air filters, and absorbent materials.

Needle punching is a mechanical process that interlocks fibers to create a web. This technique involves passing a web of fibers through a series of barbed needles that repeatedly penetrate and entangle the fibers, resulting in a cohesive fabric. Needle-punched nonwovens are known for their high tensile strength and durability, making them suitable for applications such as carpet underlays, automotive interiors, and insulation materials.

Each of these nonwoven fabric production techniques offers unique benefits and is suited to particular end-uses. By understanding the intricacies of spunbond, meltblown, and needle punching methods, manufacturers can select the appropriate process to meet the specific requirements of their products, ensuring optimal performance and functionality.

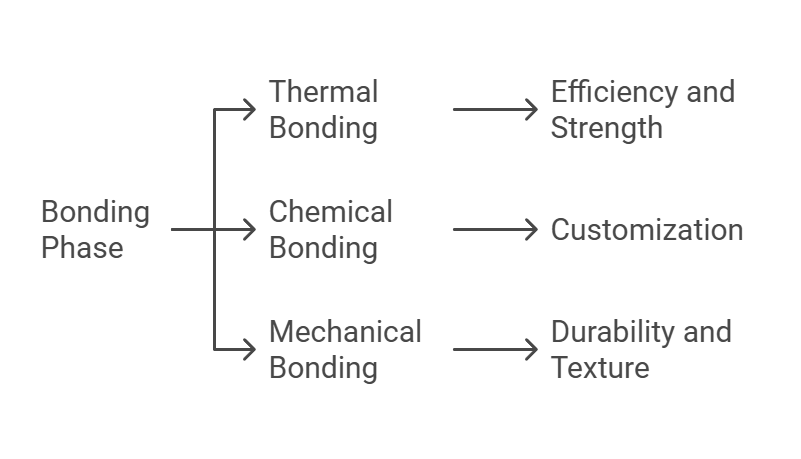

Bonding Methods in Nonwoven Manufacturing

Bonding is a pivotal phase in the nonwoven manufacturing process, responsible for fusing individual fibers into a unified, durable fabric. The primary bonding methods employed include thermal bonding, chemical bonding, and mechanical bonding, each contributing distinct properties to the end product.

Thermal bonding involves the application of heat to bond fibers. This method typically uses thermoplastic fibers that melt when exposed to elevated temperatures. Upon cooling, the melted fibers solidify, creating a strong bond between them. Thermal bonding is advantageous for its efficiency and the strength it imparts to the fabric. However, it may be less suitable for fibers that are not thermally responsive.

Chemical bonding utilizes adhesives or binders to join fibers. This method can involve the application of liquid or powder-based chemicals that, when cured, form a cohesive fabric. Chemical bonding allows for a high degree of customization in terms of fabric properties, such as softness, absorbency, and strength. The choice of chemical binder can significantly influence the characteristics of the final product, making this method versatile for various applications. Nonetheless, the potential environmental impact of chemical residues must be carefully managed.

Mechanical bonding, also known as needlepunching or hydroentanglement, relies on physical forces to entangle fibers. In needlepunching, barbed needles repeatedly penetrate the fiber web, entangling the fibers through mechanical action. Hydroentanglement, on the other hand, uses high-pressure water jets to intertwine fibers. Mechanical bonding methods are particularly advantageous for producing fabrics with high tensile strength and durability. They are also well-suited for creating nonwovens with unique textures and patterns.

Each bonding method in nonwoven manufacturing offers distinct advantages and can be selected based on the desired properties of the final fabric. Understanding these methods is essential for optimizing the manufacturing process and producing high-quality nonwoven materials tailored to specific applications.

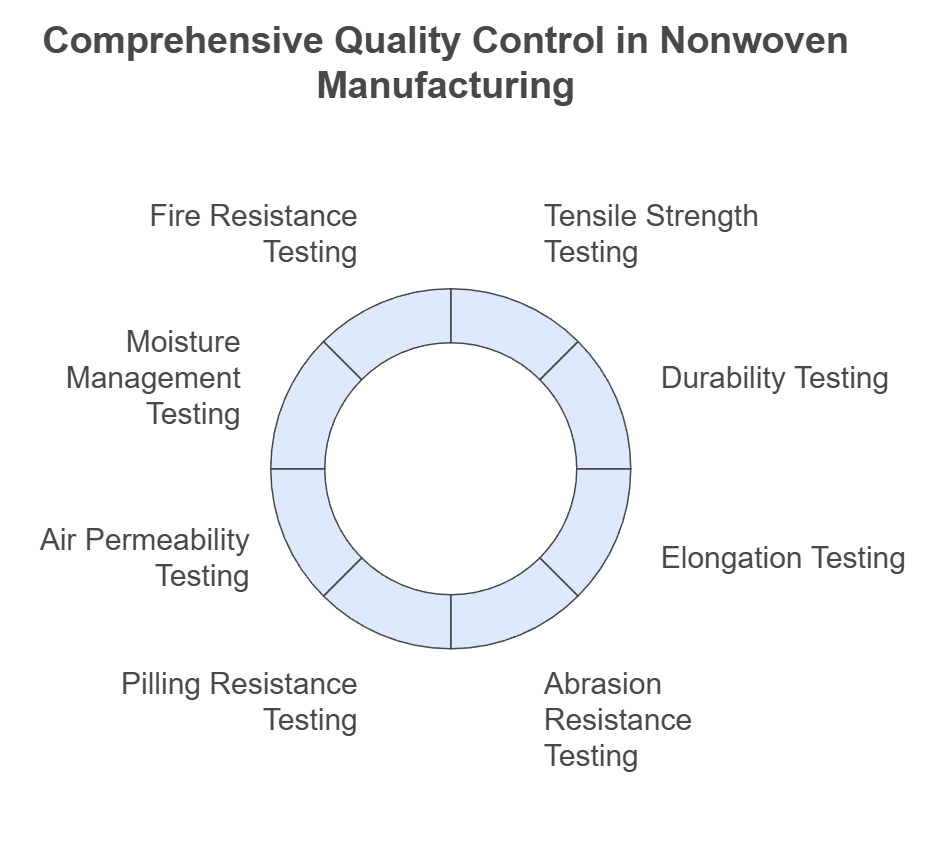

Quality Control in Nonwoven Manufacturing

Ensuring the quality of nonwoven fabrics is paramount to their performance and reliability across various applications. Quality control measures in nonwoven manufacturing encompass a broad spectrum of testing techniques, aimed at verifying the integrity, strength, and durability of the final product. These rigorous procedures are critical in maintaining the standards necessary for high-quality fabric production.

One of the primary quality control processes involves testing the tensile strength of the nonwoven fabric. This property is crucial as it determines the fabric’s ability to withstand stretching and pulling forces during usage. Tensile strength tests typically involve subjecting the fabric to controlled tension until it breaks, providing valuable data on its mechanical robustness. Additionally, elongation tests are conducted to assess how much the fabric can stretch before breaking, which is particularly important for applications requiring flexibility.

Durability testing is another essential aspect of quality control in nonwoven manufacturing. These tests evaluate the fabric’s resistance to wear and tear over time. Abrasion resistance tests, for example, simulate the conditions of repetitive friction to ensure the fabric can endure prolonged use without significant degradation. Pilling resistance tests are also performed to check the fabric’s tendency to form small balls of fiber on its surface, which can affect both appearance and performance.

Furthermore, quality control measures include testing for other critical properties such as air permeability, which is vital for applications requiring breathability, and moisture management, which is essential for products like medical textiles and hygiene products. Fire resistance tests are conducted for fabrics intended for use in environments where flame retardancy is necessary.

Advanced quality control techniques, such as automated optical inspection systems, are increasingly being adopted. These systems use high-resolution cameras and sophisticated algorithms to detect defects at various stages of the production process, ensuring that only fabrics meeting stringent quality criteria proceed to the market.

In summary, the meticulous quality control procedures in nonwoven manufacturing are indispensable for producing fabrics that meet the high standards required in diverse applications. By systematically evaluating properties such as strength, durability, and specialized functionalities, manufacturers ensure that their nonwoven products are reliable, safe, and effective for their intended uses.

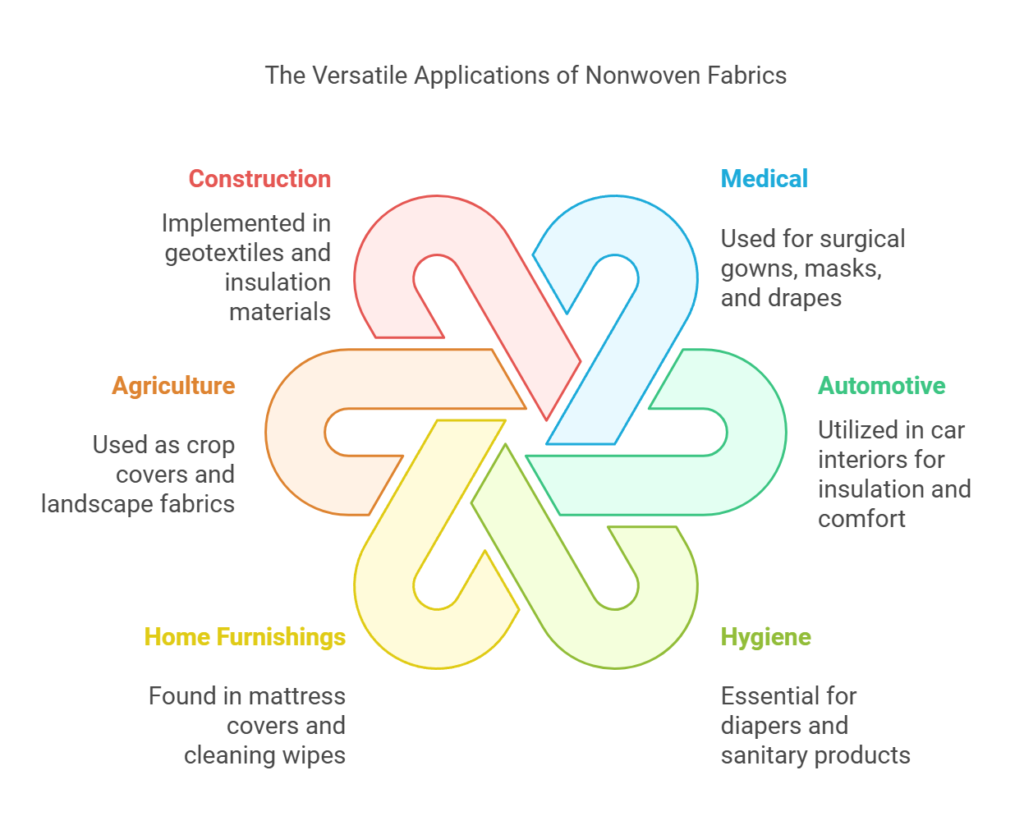

Applications of Nonwoven Fabrics

Nonwoven fabrics are essential in numerous industries due to their versatility and ability to meet specific performance requirements. One of the most prominent areas where nonwoven fabrics are utilized is in the medical field. Here, they are used to manufacture surgical gowns, masks, drapes, and other medical disposables. The fabric’s ability to provide barrier properties, breathability, and sterilizability makes it ideal for such applications, ensuring both patient and healthcare worker safety.

In the automotive industry, nonwoven fabrics are pivotal in creating interior components. These materials are used in headliners, carpets, seat covers, and trunk liners. Nonwoven fabrics offer advantages such as sound insulation, lightweight properties, and cost-effectiveness, which contribute to enhancing vehicle comfort and fuel efficiency. Their adaptability allows manufacturers to meet the stringent quality and performance standards demanded by the automotive sector.

Hygiene products represent another significant application of nonwoven fabrics. Items such as diapers, sanitary pads, and adult incontinence products rely on nonwoven materials for their absorbency, softness, and skin-friendly characteristics. The ability to combine various fibrous materials results in products that can efficiently manage moisture while providing comfort to the user.

Beyond medical, automotive, and hygiene applications, nonwoven fabrics are also found in home furnishings, agriculture, and construction. In home furnishings, they are used in products like mattress covers, upholstery, and cleaning wipes. In agriculture, nonwoven fabrics serve as crop covers and landscape fabrics, offering protection against pests and weeds while promoting plant growth. In the construction industry, they are implemented in geotextiles, roofing, and insulation materials, providing durability, filtration, and reinforcement.

The diverse applications of nonwoven fabrics highlight their importance in our daily lives. Their unique properties and adaptability make them indispensable across various sectors, underscoring the critical role they play in modern manufacturing and product development.

FAQs About Nonwoven Manufacturing

Nonwoven manufacturing has garnered significant attention due to its versatility and the variety of applications it supports. Below, we address some of the most frequently asked questions about this innovative process.

What is the Environmental Impact of Nonwoven Production?

One common concern is the environmental footprint of nonwoven manufacturing. The production process for nonwovens can be more eco-friendly compared to traditional textiles. Nonwoven materials often use fewer raw materials and generate less waste. Additionally, advancements in technology have enabled the use of recycled fibers, further reducing environmental impact. The industry is also focusing on biodegradable and sustainable options to minimize ecological repercussions.

How Do Nonwovens Differ from Traditional Fabrics?

Nonwoven fabrics are distinct from traditional woven or knitted textiles. Unlike traditional fabrics, which are created by interlacing yarns, nonwovens are produced by bonding fibers together using mechanical, thermal, or chemical methods. This results in a fabric that can be engineered to possess specific properties such as increased tensile strength, enhanced absorbency, or tailored permeability. These unique characteristics make nonwoven fabrics suitable for a wide range of applications, from medical supplies to automotive components.

What are the Future Trends in the Nonwoven Industry?

The future of nonwoven manufacturing is promising, with several emerging trends shaping the industry. Innovations are steering towards smarter, more functional nonwovens, incorporating advanced features like antimicrobial properties, improved durability, and enhanced comfort. The rise of eco-conscious consumerism is pushing the industry towards more sustainable practices, including the development of biodegradable nonwoven materials. Additionally, technological advancements such as automation and digitalization are optimizing production efficiency and reducing costs, paving the way for broader adoption of nonwoven fabrics across various sectors.

Understanding these aspects provides a comprehensive view of the current state and future directions of nonwoven manufacturing. As the industry evolves, it continues to offer exciting possibilities for both manufacturers and consumers alike.

15 Responses

Ny weekly I really like reading through a post that can make men and women think. Also, thank you for allowing me to comment!

Great post. I was checking constantly this blog and I’m impressed! Extremely useful information particularly the last part 🙂 I care for such info a lot. I was looking for this particular info for a very long time. Thank you and good luck.

Thank you for your kind words! Glad you found it useful. 😊

Mat6tube I like the energy you’ve devoted to this, regards for sharing such impressive content

Thank you so much for your kind words! We’re thrilled that you appreciate the content we’ve shared. Your support means a lot to us, and we hope to continue bringing you more valuable information.

FlixHQ As the admin is diligently working, it’s no surprise this site will gain popularity for its great content.

Thank you so much for your kind words! We’re committed to providing high – quality content, and your support means a lot to us. Here’s to a great year ahead on non – woven.com!

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Thank you so much for taking the time to read our article and for leaving your comment. We truly appreciate your feedback.

Could you please let us know which specific parts of the article you have doubts about? Your detailed questions will enable us to provide more targeted and clear explanations. We’ll do our best to address your concerns and clarify any confusion as soon as possible.

Looking forward to your reply.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thank you for your comment! I’m glad you brought up your doubts. Could you please share more specifically what aspects of the article confused you? We’re always looking to clarify and improve.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Glad it helped! We’ll be adding more related content soon. Stay tuned.

I’m really inspired together with your writing abilities as smartly

as with the format on your blog. Is this a paid subject or

did you modify it yourself? Either way keep up the excellent high quality writing,

it’s uncommon to peer a nice weblog like this one these days.

Stan Store alternatives!

Thank you so much for your kind words! It’s not a paid topic. I create and format everything myself. I’m glad you enjoy the blog, and I’ll definitely keep up the good work.