Introduction

Non-woven head caps are an essential component in numerous industries, providing a practical solution for maintaining hygiene and safety standards. These disposable caps are made from non-woven fabric, a material known for its durability, breathability, and cost-effectiveness. They are widely used in medical, food processing, pharmaceutical, and industrial environments where contamination control is crucial.

The significance of non-woven head caps lies in their ability to prevent hair and other particulates from contaminating sensitive areas. In healthcare settings, for instance, these caps are critical for both patient and staff safety, reducing the risk of infection. Similarly, in the food industry, non-woven head caps help maintain sanitary conditions, ensuring that food products remain uncontaminated during processing and packaging.

Understanding the various aspects of non-woven head caps, such as their material properties, manufacturing processes, and specific applications, is important for professionals across different sectors. This knowledge not only aids in selecting the appropriate type of head cap for specific needs but also enhances compliance with industry standards and regulations. As we delve deeper into the specifics of non-woven head caps, it becomes evident why they are a staple in environments where cleanliness and safety are paramount.

Answer to Key Question

Non-woven head caps are essential items in various industries, including healthcare, food processing, and manufacturing. The key question often posed is: “What are the primary benefits of using non-woven head caps?” To address this, it is crucial to examine their attributes and applications comprehensively.

Non-woven head caps, primarily made from polypropylene, offer several significant advantages. First and foremost, they provide superior hygiene. Unlike woven fabrics, non-woven materials have a dense structure that prevents the penetration of contaminants, making them ideal for sterile environments such as hospitals and laboratories. This attribute ensures that non-woven head caps maintain stringent cleanliness standards, thereby reducing the risk of infection and cross-contamination.

Additionally, non-woven head caps are lightweight and breathable. The porous nature of the material allows for adequate airflow, ensuring comfort for users during extended periods of wear. This is particularly beneficial in high-temperature settings, where maintaining comfort is crucial for productivity and overall well-being.

Durability is another notable benefit. Despite being lightweight, non-woven head caps are robust and resistant to wear and tear. This durability ensures that they can withstand the demands of various industrial applications, from food handling to electronic manufacturing, without compromising their protective qualities.

Cost-effectiveness is a further advantage. Non-woven head caps are generally more affordable than their woven counterparts, providing an economical solution for businesses that require large quantities of disposable headwear. Their single-use nature eliminates the need for laundering, further reducing operational costs and simplifying supply chain management.

Lastly, non-woven head caps are environmentally friendly. Many are designed to be biodegradable or recyclable, aligning with sustainable practices and reducing the environmental impact associated with disposable products.

In summary, the primary benefits of using non-woven head caps include superior hygiene, breathability, durability, cost-effectiveness, and environmental sustainability. These attributes make them an indispensable choice across various sectors, ensuring both protection and comfort for users.

What are Non-Woven Head Caps?

Non-woven head caps are a type of headwear primarily designed for hygiene and safety purposes across various industries. Unlike traditional woven fabrics, non-woven materials are created by bonding fibers together through chemical, mechanical, heat, or solvent treatment. This results in a fabric-like material that is durable, lightweight, and breathable.

The materials used in the production of non-woven head caps include polypropylene, polyester, and other synthetic fibers. Polypropylene is the most commonly used material due to its cost-effectiveness, versatility, and excellent barrier properties. These materials are chosen for their ability to provide effective protection against contaminants, making non-woven head caps ideal for use in medical, food processing, and cleanroom environments.

One of the unique properties of non-woven head caps is their breathability. The structure of non-woven fabrics allows for air permeability, which helps to keep the wearer cool and comfortable while maintaining a high level of protection. Additionally, non-woven head caps are often designed to be disposable, ensuring that they can be easily replaced to maintain hygiene standards.

Another distinguishing characteristic of non-woven head caps is their resistance to fluids. This property is particularly important in medical and laboratory settings where exposure to liquids and bodily fluids is common. The non-woven material acts as an effective barrier, reducing the risk of contamination and cross-infection.

Compared to other types of headwear, non-woven head caps offer several advantages. They are generally more affordable, provide superior protection, and are easier to produce in large quantities. Furthermore, their disposable nature eliminates the need for laundering, which can be both time-consuming and costly.

In summary, non-woven head caps are a vital component in maintaining hygiene and safety standards across various industries. Their unique properties, including breathability, fluid resistance, and cost-effectiveness, make them a preferred choice over traditional headwear options.

Applications of Non-Woven Head Caps

Non-woven head caps have become indispensable in numerous industries due to their lightweight, breathable, and cost-effective properties. Their primary function is to maintain hygiene and control contamination, making them a critical component in environments where these factors are paramount. In medical settings, non-woven head caps are extensively used by surgeons, nurses, and other healthcare professionals to prevent hair and scalp particles from contaminating sterile environments and open wounds. The use of these caps is crucial during surgical procedures, patient care, and laboratory work where infection control is a top priority.

In the food processing industry, non-woven head caps play a vital role in maintaining hygiene standards and ensuring the safety of food products. Workers in food processing plants wear these caps to prevent hair from falling into food products, thereby reducing the risk of contamination and adhering to stringent health regulations. These head caps are also essential in maintaining a clean environment during the preparation and packaging of food items, ensuring that the end products are safe for consumption.

Cleanrooms, which are controlled environments used in the manufacturing of sensitive products such as electronics, pharmaceuticals, and aerospace components, also rely heavily on non-woven head caps. In these settings, even the smallest contaminants can compromise the quality and functionality of the products being manufactured. Non-woven head caps help to minimize the introduction of particulate matter, thereby maintaining the integrity of the cleanroom environment and ensuring the production of high-quality products.

Beyond these primary industries, non-woven head caps are also used in various other sectors where hygiene and contamination control are critical. This includes beauty salons, spas, and laboratories, among others. The versatility and effectiveness of non-woven head caps in maintaining cleanliness and preventing contamination make them a valuable asset across a wide range of applications, ensuring safety and compliance with regulatory standards.

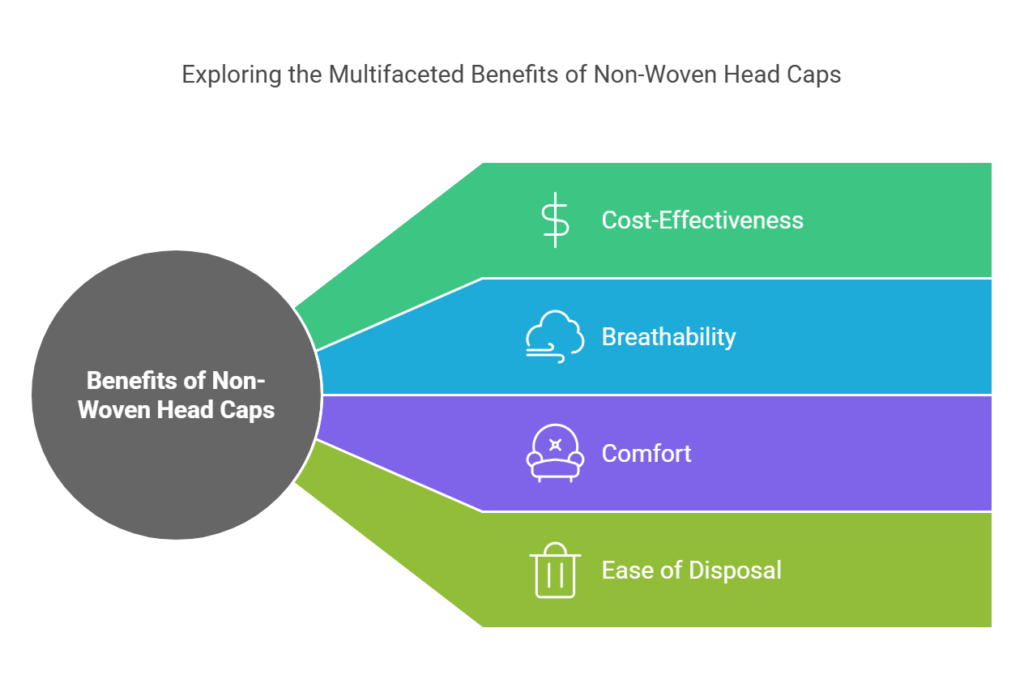

Benefits of Using Non-Woven Head Caps

Non-woven head caps offer a multitude of benefits that make them an ideal choice for various industries, including healthcare, food service, and manufacturing. One of the most notable advantages is their cost-effectiveness. Non-woven materials are generally less expensive than alternative fabrics like cotton or polyester, making them a budget-friendly option for organizations that require bulk purchases.

Another significant benefit is breathability. Non-woven head caps are designed to allow air to circulate freely, which helps in maintaining a comfortable temperature for the wearer. This is particularly important in environments where workers are required to wear head caps for extended periods. The breathability of non-woven fabric helps to reduce perspiration and discomfort, thereby improving overall workplace efficiency and morale.

Comfort is another key factor that sets non-wwoven head caps apart from other types of headwear. The softness of the non-woven material ensures that it sits comfortably on the head without causing irritation. This is especially crucial in medical settings, where healthcare professionals need to focus on patient care without being distracted by uncomfortable gear.

Ease of disposal is another critical advantage. Non-woven head caps are typically designed for single use, which eliminates the need for laundering and reduces the risk of cross-contamination. This is particularly beneficial in sterile environments like hospitals and laboratories, where hygiene is paramount. After use, these caps can be easily disposed of, ensuring a clean and safe environment.

When compared to alternative materials, non-woven head caps stand out for their unique combination of cost-effectiveness, breathability, comfort, and ease of disposal. While cotton and polyester caps may offer durability, they often come with higher costs and maintenance requirements. Non-woven head caps provide a practical solution that meets the needs of various industries without compromising on quality or safety.

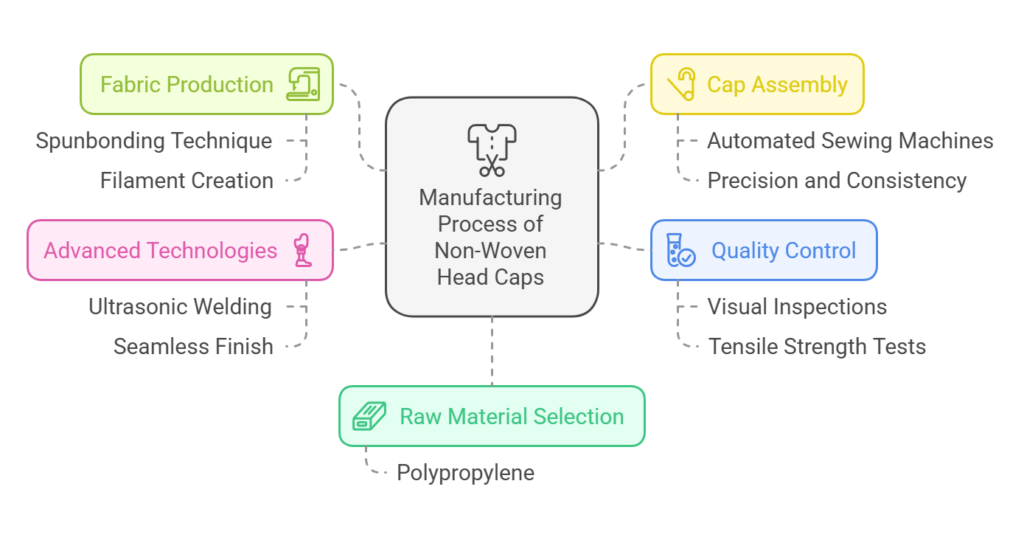

Manufacturing Process

The manufacturing process of non-woven head caps is a meticulous procedure designed to ensure high quality and efficiency. The process begins with the selection of raw materials, primarily polypropylene, which is known for its durability and lightweight properties. The raw material is processed through a series of steps, each of which plays a critical role in the final product.

The first step involves the conversion of polypropylene into non-woven fabric through a technique called spunbonding. This method involves melting the polypropylene and extruding it through fine nozzles to create filaments. These filaments are then cooled and bonded together to form a continuous sheet of non-woven fabric. The spunbonding process is essential for creating the uniform texture and strength required for non-woven head caps.

Once the non-woven fabric is produced, it is cut into smaller pieces that are suitable for head cap manufacturing. These pieces are then fed into automated sewing machines, where they are stitched and assembled into the shape of a head cap. The use of automated sewing machines ensures precision and consistency in the production process, which is vital for meeting industry standards.

After the initial assembly, the head caps undergo a series of quality control checks. These checks include visual inspections, tensile strength tests, and measurements to ensure that each cap meets the specified dimensions and quality criteria. Any defects identified during these inspections are rectified to maintain the integrity of the final product.

In addition to these steps, advanced technologies such as ultrasonic welding may also be employed to enhance the durability and comfort of the non-woven head caps. Ultrasonic welding uses high-frequency vibrations to bond materials together without the need for additional adhesives, resulting in a stronger and more seamless finish.

Overall, the manufacturing process of non-woven head caps is a well-coordinated series of steps that leverage modern technologies and stringent quality control measures. This ensures that the final product not only meets but often exceeds industry standards, providing users with reliable and effective head protection.

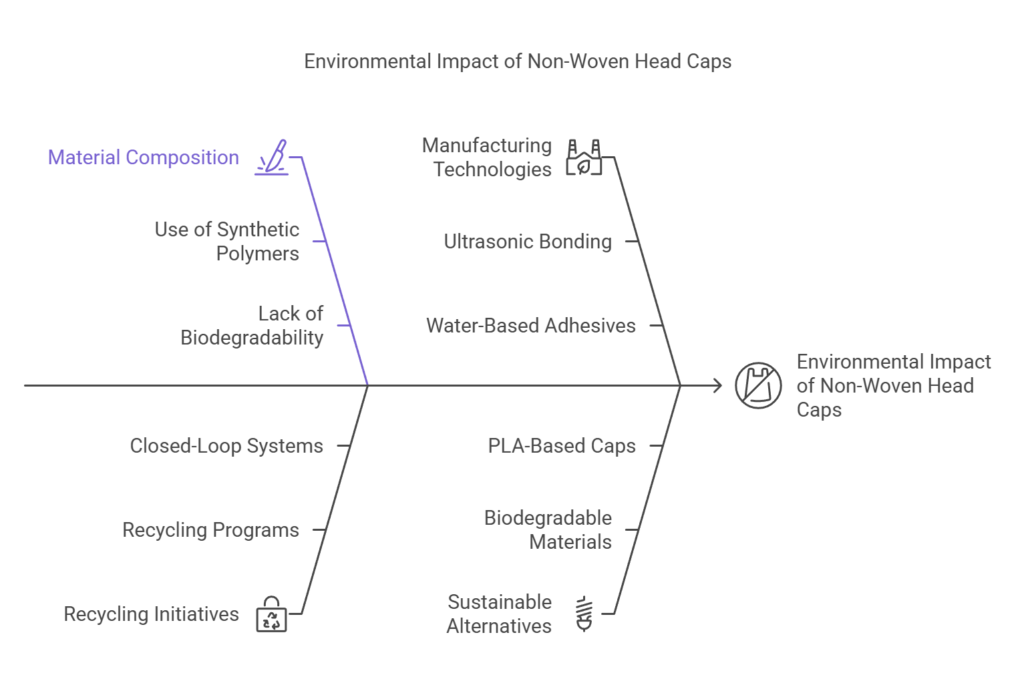

Environmental Impact

Non-woven head caps are widely used in various industries, including healthcare, food processing, and manufacturing, due to their convenience and cost-effectiveness. However, their environmental impact has become a point of concern. One primary aspect to consider is the biodegradability of the materials used in non-woven head caps. Traditional non-woven fabrics often comprise synthetic polymers like polypropylene, which are not biodegradable. These materials can persist in the environment for hundreds of years, contributing significantly to plastic pollution.

In response to these environmental challenges, there has been a growing interest in developing more sustainable alternatives. Some manufacturers are exploring the use of biodegradable materials such as polylactic acid (PLA), which is derived from renewable resources like corn starch or sugarcane. PLA-based non-woven head caps offer the advantage of breaking down more easily in natural environments, thus reducing the long-term ecological footprint.

Additionally, efforts are being made to enhance the sustainability of non-woven head caps through recycling initiatives. Recycling programs aim to reduce waste by reprocessing used caps into new products, thereby minimizing the demand for virgin materials. Some companies are also investing in closed-loop systems, where the entire lifecycle of the product, from production to disposal, is managed in a way that promotes environmental responsibility.

Moreover, advancements in manufacturing technologies are contributing to reduced environmental impact. Innovations such as ultrasonic bonding and water-based adhesives are replacing traditional chemical bonding methods, resulting in lower emissions and reduced use of harmful substances. These technologies not only improve the environmental profile of non-woven head caps but also enhance their safety and performance.

In conclusion, while non-woven head caps present certain environmental challenges, ongoing efforts in material innovation, recycling, and sustainable manufacturing practices are paving the way for more eco-friendly solutions. As the industry continues to evolve, it is crucial to balance the benefits of these products with their ecological impact to ensure a more sustainable future.

Frequently Asked Questions (FAQs)

Non-woven head caps play a crucial role in various industries, offering both hygiene and comfort. Here, we address some of the most commonly asked questions regarding their proper usage, storage, disposal, and other related concerns.

How should non-woven head caps be used?

Non-woven head caps are designed for single-use applications. To wear one, simply place the cap over your head, ensuring that all hair is covered. The elastic band should rest comfortably around the forehead and the nape of the neck, securing the cap in place. They are particularly beneficial in environments where maintaining hygiene is paramount, such as hospitals, laboratories, and food processing plants.

What is the best way to store non-woven head caps?

Proper storage of non-woven head caps is essential to maintain their effectiveness. They should be kept in a cool, dry place, away from direct sunlight and moisture. Store them in their original packaging until needed, as this helps to prevent contamination and degradation of the material.

How should non-woven head caps be disposed of?

Non-woven head caps are typically designed for single-use and should be disposed of responsibly after use. They should be placed in a proper waste disposal container to prevent any contamination. In specific industries, such as medical or food sectors, it is crucial to follow the disposal guidelines set by regulatory bodies to ensure compliance and safety.

Are there any common misconceptions about non-woven head caps?

One common misconception is that non-woven head caps can be reused. It is important to note that these caps are intended for single-use only to ensure maximum hygiene and effectiveness. Another misconception is that they are uncomfortable to wear; however, modern non-woven head caps are designed with comfort in mind, using lightweight and breathable materials.

By addressing these frequently asked questions, we aim to provide clarity on the proper use, storage, and disposal of non-woven head caps, ensuring that they serve their purpose effectively in maintaining hygiene and safety standards across various industries.

4 Responses

Usually I do not read article on blogs however I would like to say that this writeup very compelled me to take a look at and do it Your writing style has been amazed me Thank you very nice article

Thank you for your kind words regarding my blog post. I’m pleased to hear that the content was compelling enough for you to read, even though you don’t typically engage with blog articles.

I appreciate the feedback on my writing style – it’s always gratifying to know that the way I present information is effective and engaging for readers. My aim is to create helpful, well-written content, so your positive comments are greatly valued.

Thank you very much for taking the time to provide this nice article feedback. It’s feedback like yours that motivates me to continue producing high-quality content. I’m glad you found the article to be a worthwhile read.

Hi

I am kalinga srilanka

I want know how to check doctor cap depth

Please reply video

Hi, unfortunately, we don’t have a relevant video for now. You can measure the doctor cap depth from the top of the cap to the bottom along the center. Hope this helps.