ang domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /home/u585319850/domains/non-woven.com/public_html/wp-includes/functions.php on line 6121elementor domain was triggered too early. This is usually an indicator for some code in the plugin or theme running too early. Translations should be loaded at the init action or later. Please see Debugging in WordPress for more information. (This message was added in version 6.7.0.) in /home/u585319850/domains/non-woven.com/public_html/wp-includes/functions.php on line 6121We specialize in manufacturing Metallic Laminated Non-Woven Fabrics. Our lamination capabilities range from 20 gsm to 120 gsm, with a maximum width of 1600mm. We offer a wide range of colors, including Metallic Gold, Metallic Silver, Metallic Copper, Metallic Red, Metallic Blue, Metallic Purple, and Metallic Pink. For custom colors, we require a minimum order quantity and Pantone shade reference.

| Gsm | 75-150gsm |

|---|---|

| Color | Black |

| Material | Polypropylene+PET, PP+PE+PET |

| MOQ | 1 Ton |

| Usage | Bag, Floral arrangements and bouquets, Gift wrapping and packaging, Tablecloth |

Laminated nonwoven fabric is a versatile and durable material that combines the benefits of nonwoven fabric with the added strength and functionality of a laminated layer. This innovative product is widely used in various industries for its excellent performance and diverse applications.

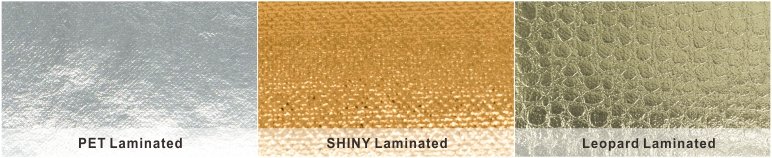

Now, we are proud to present our exceptional collection of metal laminated nonwoven fabrics:

(Various color and emboss to be chozen)

Main Application: Shopping bags, Gift bag, packaging material , packaging bag, table cloth,etc

Our PET laminated nonwoven fabric combines the strength and durability of nonwoven fabric with the added protection of a PET laminated layer. It offers excellent tear resistance, water repellency, and barrier properties, making it ideal for various applications requiring enhanced performance.

Experience the brilliance of our SHINY laminated nonwoven fabric. With its metallic finish and superior quality, this fabric adds a touch of elegance and sophistication to your products. It is perfect for applications that demand both functionality and aesthetics, such as fashion accessories, packaging, and decorative items.

Unleash your creativity with our LEPARD laminated nonwoven fabric. This fabric features a unique leopard print design, adding a trendy and fashionable element to your projects. It is versatile, durable, and perfect for applications in fashion, home decor, and crafts.

Our metal laminated nonwoven fabrics offer a range of benefits, including enhanced strength, water resistance, barrier protection, and aesthetic appeal. Whether you need reliable performance, a shiny metallic finish, or a trendy pattern, our PET Laminated Nonwoven, SHINY Laminated Nonwoven, and LEPARD Laminated Nonwoven Fabric have got you covered. Choose our fabrics for exceptional quality and endless possibilities in your next project.

Nonwoven Fabric Base: The laminated nonwoven fabric starts with a base layer of nonwoven fabric, which provides softness, breathability, and flexibility. The nonwoven fabric is made from synthetic fibers that are bonded together through a mechanical or chemical process, resulting in a strong and cohesive material.

Laminated Layer: The nonwoven fabric is enhanced with a laminated layer, which is bonded to one or both sides of the fabric. The lamination process involves applying a thin layer of polymeric film or coating to the fabric, providing additional strength, water resistance, and barrier properties.

Enhanced Strength and Durability: The lamination process significantly enhances the strength and durability of the nonwoven fabric. The laminated layer adds a protective barrier that improves tear resistance, puncture resistance, and overall structural integrity, making it suitable for demanding applications.

Water Resistance and Barrier Properties: The laminated nonwoven fabric offers excellent water resistance, preventing liquids from penetrating through the fabric. It also provides a barrier against dust, dirt, and other contaminants, making it ideal for applications requiring cleanliness and protection.

Versatility: Laminated nonwoven fabric has a wide range of applications across various industries. It is commonly used in sectors such as healthcare, hygiene products, packaging, agriculture, construction, and automotive, among others. Its versatility makes it a preferred choice for manufacturers and designers seeking reliable and high-performance materials.

Customizable Options: Laminated nonwoven fabric can be customized to meet specific requirements. This includes variations in thickness, weight, color, and lamination patterns. Customization options ensure that the fabric aligns perfectly with the intended application, providing optimal performance and aesthetics.

Eco-Friendly Considerations: Laminated nonwoven fabric can be manufactured using eco-friendly materials and production processes. This includes using recyclable or biodegradable materials for the nonwoven fabric base and laminated layer, minimizing environmental impact.

Hygiene Products: Laminated nonwoven fabric is widely used in the production of diapers, sanitary napkins, and adult incontinence products. The water resistance and barrier properties of the fabric help maintain dryness and prevent leakage.

Medical and Healthcare: In the medical field, laminated nonwoven fabric is used for surgical gowns, drapes, and other protective apparel. The fabric’s strength, durability, and barrier properties contribute to infection control and patient safety.

Packaging: The water resistance and durability of laminated nonwoven fabric make it suitable for packaging applications. It is used for products such as tote bags, shopping bags, and promotional packaging, providing a sustainable and reusable alternative to traditional plastic materials.

Agriculture and Gardening: Laminated nonwoven fabric is employed in agricultural applications such as crop covers, weed control mats, and nursery bags. It helps protect plants from harsh weather conditions, controls weed growth, and promotes healthy plant growth.

Construction: The strength and durability of laminated nonwoven fabric make it useful in the construction industry. It is used for applications such as geotextiles, roofing underlayment, and insulation materials.

Why Choose Us for Our Metal Laminated Nonwoven Fabrics?

Exceptional Quality: We take pride in offering metal laminated nonwoven fabrics of the highest quality. Our fabrics undergo stringent quality control measures to ensure superior performance, durability, and functionality.

Wide Range of Options: With our PET Laminated Nonwoven, SHINY Laminated Nonwoven, and LEPARD Laminated Nonwoven Fabric, we provide a diverse selection to suit different needs and preferences. Whether you require enhanced strength, a shiny metallic finish, or a trendy pattern, we have the perfect fabric for your project.

Customization Capabilities: We understand the importance of customization. Our metal laminated nonwoven fabrics can be tailored to meet your specific requirements, including color, thickness, and print designs. We work closely with our clients to ensure their vision is brought to life.

Versatility in Applications: Our metal laminated nonwoven fabrics find applications across various industries. From fashion and accessories to packaging and home decor, our fabrics offer versatility and adaptability to suit different product needs.

Reliable Customer Service: We prioritize customer satisfaction and provide exceptional customer service throughout the ordering process. Our dedicated team is always ready to assist you, answer your queries, and ensure a seamless experience from start to finish.

Competitive Pricing: We offer competitive pricing without compromising on quality. Our aim is to provide cost-effective solutions for our customers, enabling them to achieve their desired results within their budget.

Choose us as your trusted partner for metal laminated nonwoven fabrics. We combine quality, customization, versatility, and excellent customer service to deliver outstanding products that meet your unique requirements. Experience the difference with our exceptional range of PET Laminated Nonwoven, SHINY Laminated Nonwoven, and LEPARD Laminated Nonwoven Fabric.

Production Process of Our Metal Laminated Nonwoven Fabrics:

Material Selection: We start by carefully selecting high-quality materials for our metal laminated nonwoven fabrics. The base nonwoven fabric is chosen for its strength, durability, and compatibility with the lamination process.

Lamination: The lamination process involves bonding a layer of metal coating or PET film to the nonwoven fabric. This is achieved through precise heat and pressure application, ensuring a strong and seamless bond between the layers.

Coating Application: For PET Laminated Nonwoven, a thin layer of PET film is uniformly applied to the nonwoven fabric using advanced coating techniques. This process enhances the fabric’s barrier properties, water resistance, and durability.

Metallic Finish: Laminated Nonwoven undergoes an additional step to achieve its captivating metallic finish. Through specialized methods, a metallic coating is applied to the nonwoven fabric, creating a shiny and reflective surface.

Quality Control: Throughout the production process, our dedicated quality control team conducts rigorous inspections to ensure that each roll of metal laminated nonwoven fabric meets our strict quality standards. This includes checking for uniform lamination, proper adhesion, color accuracy, and overall fabric integrity.

Customization: We understand the importance of customization in meeting our customers’ specific requirements. Our production process allows for customization options such as color variations, thickness adjustments, and pattern designs, ensuring that our fabrics perfectly align with our customers’ needs.

Packaging and Delivery: Once the production and quality control processes are complete, our metal laminated nonwoven fabrics are carefully packaged to protect them during transportation. We prioritize efficient logistics management to ensure timely delivery to our customers.

At every stage of the production process, we adhere to strict quality control measures to ensure that our metal laminated nonwoven fabrics are of the highest quality, durability, and functionality. With our meticulous production process, we guarantee fabrics that will exceed your expectations in performance and aesthetics.

Laminated nonwoven fabric is a versatile and durable material that combines the benefits of nonwoven fabric with the added strength and functionality of a laminated layer. Its enhanced strength, water resistance, and barrier properties make it suitable for a wide range of applications in industries such as hygiene products, medical and healthcare, packaging, agriculture, and construction. With customizable options and eco-friendly considerations, laminated nonwoven fabric offers a reliable and sustainable solution for manufacturers and designers seeking high-performance materials.

We will contact you within 1 working day, please pay attention to the email with the suffix “@non-woven.com”.