Introduction

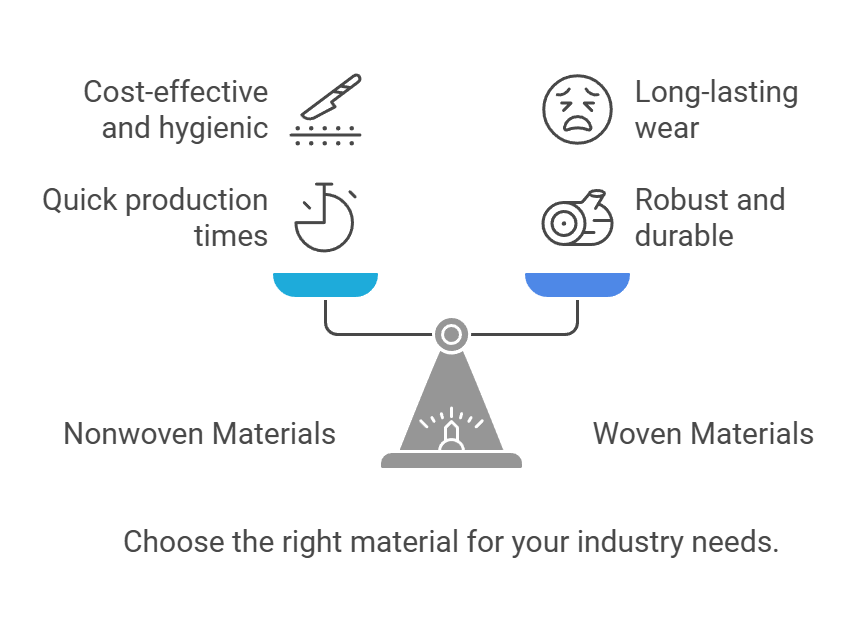

In diverse industrial applications—including textiles, healthcare, and construction—the question of whether to use nonwoven or woven materials frequently arises. These two types of materials, although seemingly similar in function, possess distinct characteristics and excel in different contexts. In industries where the choice of material impacts durability, flexibility, and cost, understanding the differences between nonwoven and woven fabrics becomes crucial.

Nonwoven materials are generally manufactured by bonding fibers together through mechanical, thermal, or chemical means. They are often preferred for their quick production times and inexpensive raw materials. Conversely, woven materials are created by interlacing two sets of threads at right angles, resulting in a more robust and durable fabric. This traditional method of fabric production has stood the test of time in terms of strength and reliability.

The decision between using nonwoven or woven materials can significantly affect the performance and suitability of the end product. For instance, in the healthcare industry, nonwoven fabrics are frequently used for disposable items such as surgical gowns and face masks, owing to their cost-effectiveness and hygienic properties. Meanwhile, in the textiles industry, woven materials predominate in applications requiring long-lasting wear and comfort, such as apparel and upholstery.

Given the critical role that material choice plays in product performance across various industries, a thorough understanding of nonwoven and woven fabrics is indispensable. The following sections will delve deeper into the unique characteristics, advantages, and disadvantages of each type, helping you make an informed decision tailored to your specific needs.

What Are Woven Fabrics?

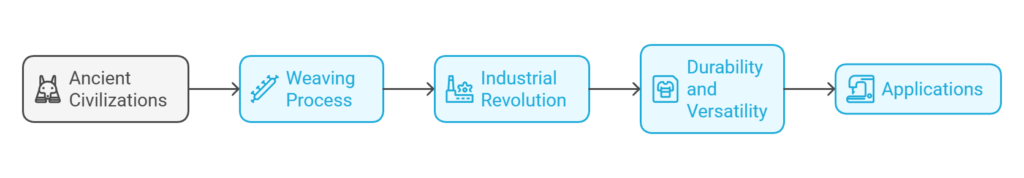

Woven fabrics have been an integral part of human civilization for thousands of years, tracing back to ancient civilizations like Egypt and Mesopotamia. These fabrics are created through a meticulous weaving process that involves interlacing two sets of yarns or threads at right angles. The horizontal threads are known as weft, while the vertical threads are called warp. The loom is the primary tool used in the weaving process, and it can range from simple handlooms to advanced automated machines.

The history of woven fabrics is rich and varied, reflecting the evolution of textile technology over the centuries. Initially, weaving was a manual process, but with the advent of the Industrial Revolution, mechanized looms revolutionized fabric production, making it faster and more efficient.

The defining characteristic of woven fabrics is their durability and versatility. The tight interlacing of threads makes them strong and less prone to stretching, ensuring longevity. Woven fabrics come in a myriad of textures, weights, and patterns, ranging from delicate, sheer materials to heavy, durable textiles. This variability makes them suitable for a broad range of applications, including clothing, home furnishings, medical textiles, and industrial uses.

One of the significant benefits of woven fabrics is their stability. The structure of the fabric provides dimensional stability, which means it retains its shape and does not distort easily. This is particularly advantageous in apparel, where fit and form are crucial. Additionally, woven fabrics are often breathable and can be designed to be water-resistant or even waterproof, further expanding their use cases.

In conclusion, woven fabrics, with their robust and versatile nature, play a critical role in various industries. Their manufacturing process, rooted in historical traditions yet enhanced by modern technology, ensures that these fabrics continue to meet diverse needs efficiently. The enduring reliability and adaptability of woven materials make them a preferred choice for many applications, from everyday clothing to specialized industrial products.

What Are Nonwoven Fabrics?

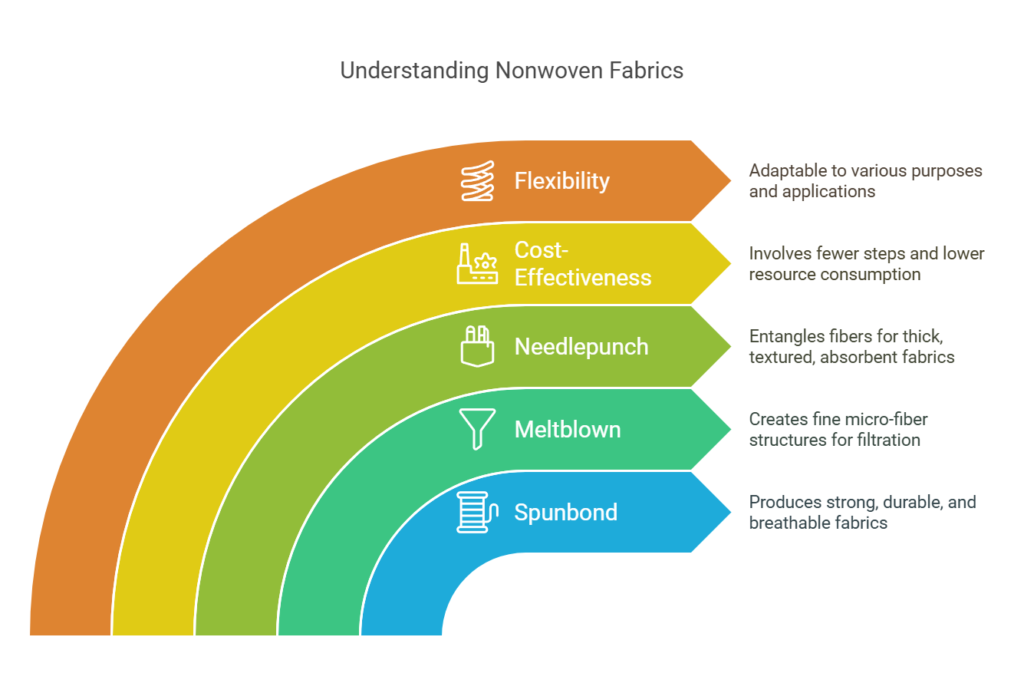

Nonwoven fabrics are materials made without weaving or knitting. These fabrics are created through unique manufacturing processes that bond fibers together mechanically, thermally, or chemically. One of the standout characteristics of nonwoven fabrics is their versatility, making them suitable for a wide range of applications. The key methods used in manufacturing nonwoven materials include spunbond, meltblown, and needlepunch.

Spunbond nonwoven fabrics are produced by extruding polymers to form continuous filaments, which are then laid into a web and bonded. This method results in materials that are strong, durable, and breathable. Meltblown nonwoven fabrics, on the other hand, are created by extruding melted polymer fibers that are subsequently stretched and cooled by high-velocity air. This process makes the fabric particularly effective for filtration applications due to its fine, micro-fiber structure.

Needlepunch nonwovens involve the entanglement of fibrous webs using barbed needles, creating a fabric that is thick and textured. This method is often used for applications where durability and absorbency are critical, such as in geotextiles and industrial liners.

Nonwoven fabrics offer numerous benefits including cost-effectiveness, as their production typically involves fewer steps and lower resource consumption compared to woven materials. Their flexibility makes them adaptable to various purposes, from medical supplies to consumer products. Moreover, many nonwoven fabrics are designed to be disposable, providing convenience and hygiene, especially in single-use scenarios like medical gowns and face masks.

To sum up, nonwoven fabrics are highly valued for their diverse range of applications and beneficial properties. Their unique manufacturing processes like spunbond, meltblown, and needlepunch contribute to the distinctive features of these materials, making them an integral part of various industries due to their cost-effectiveness, flexibility, and disposability.

Key Differences Between Nonwoven and Woven Materials

Understanding the fundamental differences between nonwoven and woven materials is imperative to determine which type is most suited for specific needs. Various factors play a critical role in influencing these differences and overall applicability of the materials. Below is a side-by-side comparison addressing key aspects such as strength, durability, flexibility, cost, and environmental impact.

Strength

Woven materials generally exhibit superior strength owing to their interlocking fabric structure, which provides tensile strength in multiple directions. On the contrary, nonwoven materials typically exhibit varying degrees of strength depending on how they are bonded, whether thermally, mechanically, or chemically.

Durability

When it comes to durability, woven fabrics often last longer due to their robust structure, making them ideal for applications requiring prolonged use, like in apparel and upholstery. Nonwoven materials, however, tend to be less durable over extended periods, although advances in technology have created more durable variants for specific immediate-use scenarios.

Flexibility

Nonwoven materials often offer greater flexibility, making them suitable for applications such as disposable medical supplies and packaging materials. Woven materials, while typically less flexible, provide sturdiness and structure better suited to more durable applications.

Cost

Nonwoven fabrics are generally more cost-effective to produce, especially at scale, contributing to their widespread use in disposable items like masks and hygiene products. Woven materials, due to the more labor-intensive manufacturing process, often come at a higher price point but offer value in their longevity and reusability.

Environmental Impact

The environmental impact of nonwoven and woven materials is nuanced. Nonwovens, often made from synthetic fibers, may contribute to waste if not biodegradable or recyclable. However, their production process can be more energy-efficient. Woven materials, particularly those sourced from natural fibers, offer better environmental sustainability but can require more resources for production.

These attributes make each type of material preferable for specific uses. For instance, nonwoven materials excel in temporary, disposable applications where cost and flexibility are priorities.In contrast, woven materials are typically chosen for long-term, durable applications requiring strength and structure.

Industries and Applications

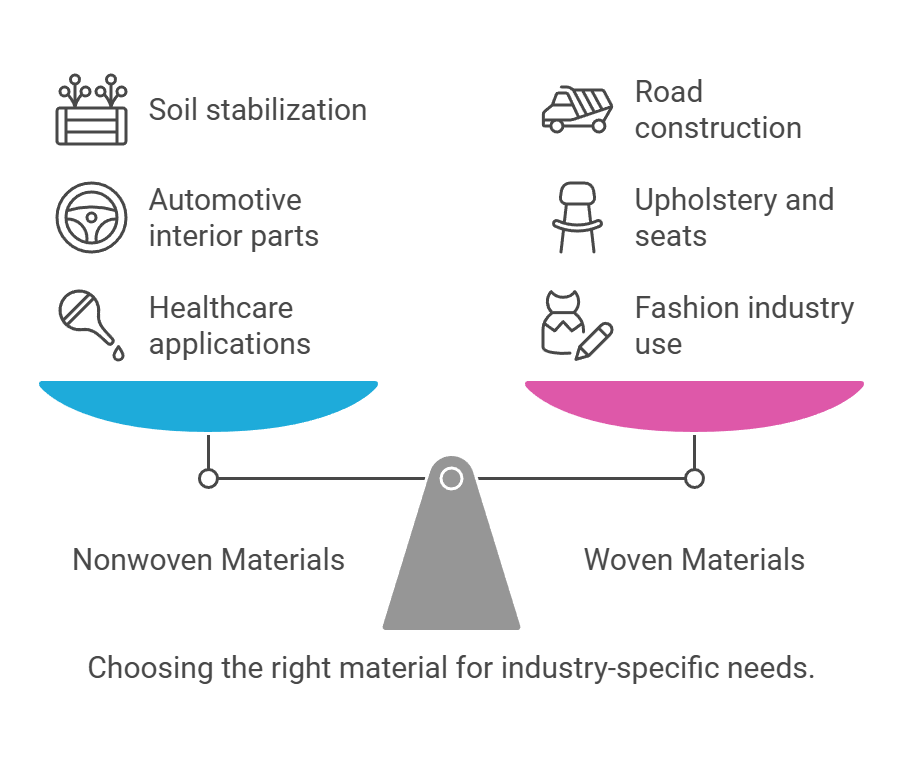

Both nonwoven and woven materials find extensive use across a multitude of industries, owing to their distinct properties and capabilities. Each type of material meets specific requirements, shaping their applications in unique ways.

In the healthcare sector, nonwoven materials are particularly valued for their single-use, cost-effective, and sterile qualities. For instance, nonwoven fabrics are the preferred choice for surgical masks, medical gowns, and disposable drapes. Their inherent characteristics of breathability, fluid resistance, and compatibility with sterilization processes make them ideal for such critical applications.

Conversely, woven fabrics are cherished in the fashion industry, primarily for high-end garments and accessories. The durability, breathability, and sophisticated appearance of woven textiles make them indispensable for producing tailored suits, dresses, and high-quality fashion items. The precision and intricacy achieved through the weaving process enable designers to create luxurious and textured pieces that satisfy the discerning tastes of fashion connoisseurs.

The automotive industry also leverages both types of materials, but in different capacities. Nonwoven fabrics are used for interior linings, insulation, and filters due to their lightweight yet robust nature. On the other hand, woven materials are employed for upholstery and seat covers, as they offer superior strength, comfort, and aesthetics.

Construction is another critical sector where material choice is vital. Nonwoven geotextiles are commonly used for soil stabilization, erosion control, and drainage applications because they provide the necessary filtration and support. Woven geotextiles, however, are preferred where strength and reinforcement are critical, such as in road construction and embankment stabilization.

Ultimately, the decision between nonwoven and woven materials is dictated by the specific needs of each industry. Factors such as durability, cost, functionality, and aesthetic appeal play significant roles in determining the most suitable material for a given application. Understanding these requirements ensures optimal performance and end-user satisfaction across various sectors.

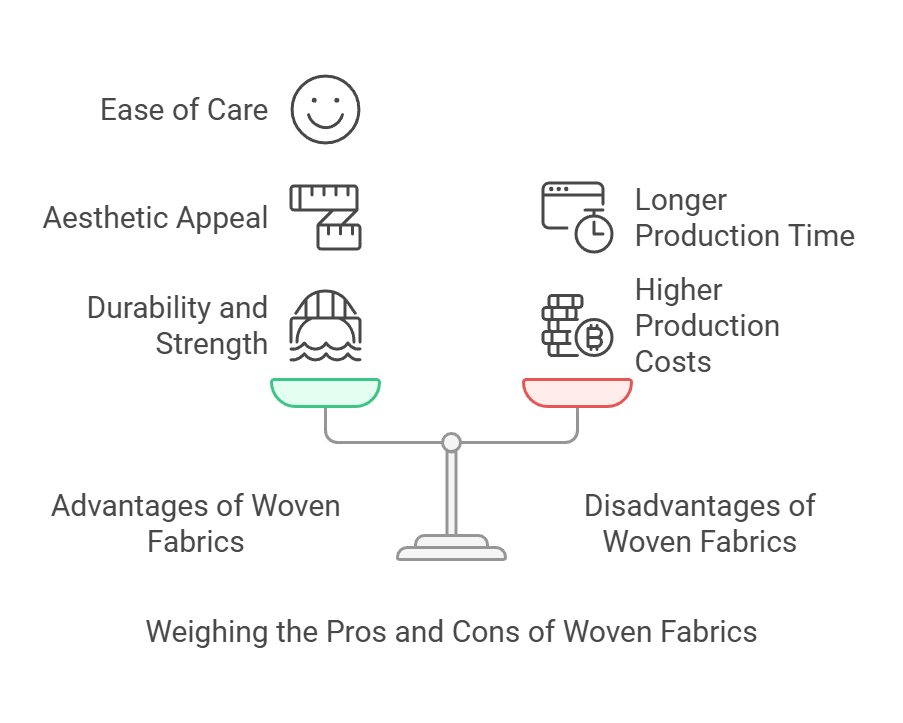

Pros and Cons of Woven Materials

Woven materials boast a range of advantages that make them a popular choice in various applications. One significant benefit of woven fabrics is their durability. These fabrics are constructed by interlacing threads in a criss-cross pattern, which results in a strong, resilient material. This makes woven fabrics ideal for products that need to withstand substantial wear and tear, such as upholstery, clothing, and industrial textiles.

Another advantage of woven materials is their aesthetic appeal. The variety of weaving techniques allows for a broad spectrum of textures, patterns, and finishes, ensuring that woven fabrics can meet diverse design preferences. The meticulous weaving process also generally results in a higher-quality appearance, adding an element of sophistication to any product.

Woven materials are also relatively easy to care for. They tend to be stable and retain their shape well, which simplifies maintenance. Most woven fabrics are machine washable and exhibit good resistance to wrinkles, making them a convenient option for everyday use.

However, woven materials do have some limitations as well. One noteworthy disadvantage is cost. The intricate process involved in producing woven fabrics can be time-consuming and labor-intensive, which often translates to higher prices. For consumers or industries operating on tight budgets, this can be a significant drawback.

Additionally, the production time for woven materials is generally longer compared to nonwoven options. The need for specialized equipment and skilled labor can slow down manufacturing processes, which might pose challenges in meeting urgent demands or large production orders.

In summary, while woven materials offer durability, aesthetic versatility, and ease of care, they come with limitations such as higher costs and longer production times. These factors should be carefully weighed when deciding whether woven fabrics are the best choice for your specific needs.

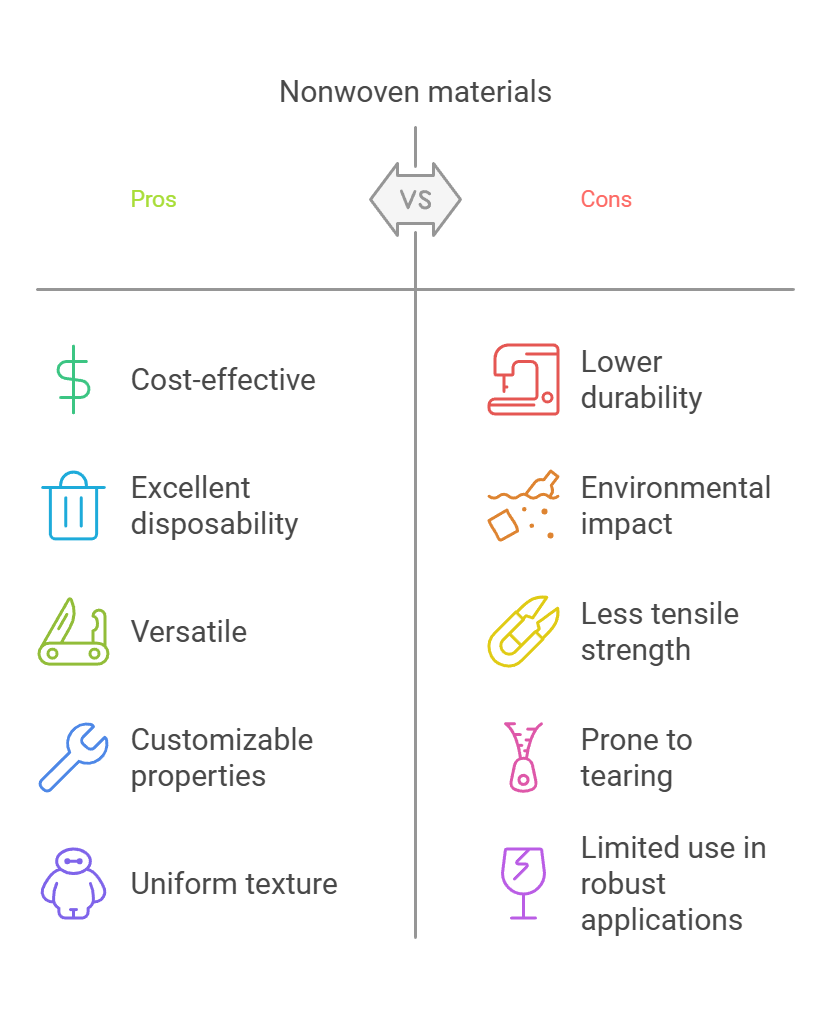

Pros and Cons of Nonwoven Materials

Nonwoven materials offer a myriad of advantages, making them a popular choice across various industries. One of the primary benefits of nonwoven materials is their cost-effectiveness. Due to the simplified production process, these materials can be produced quickly and inexpensively, providing an economical option for many applications. Additionally, nonwoven materials exhibit excellent disposability. This feature makes them particularly well-suited for single-use items in the medical field, such as surgical gowns and masks, ensuring hygiene and reducing the risk of contamination.

Versatility is another strong suit of nonwoven materials. They can be tailored to meet specific needs, offering customizable properties such as absorbency, softness, and flame resistance. This adaptability extends their utility across a range of sectors, from personal care products to automotive applications. Furthermore, nonwoven materials often display superior uniformity and consistency in texture, enhancing their functionality in precise applications.

However, nonwoven materials are not without their drawbacks. One significant limitation is their lower durability when compared to woven counterparts. Due to their structure, nonwoven materials tend to have less tensile strength and may be prone to tearing or disintegration under stress. This reduced durability can limit their use in applications requiring robust, long-lasting materials.

Additionally, the environmental impact of disposable nonwovens is a growing concern. While they offer convenience, their single-use nature contributes to waste and environmental degradation. Efforts are being made to develop biodegradable nonwoven materials, but this is an area still in need of significant advancement.

Overall, nonwoven materials present a compelling option for specific applications due to their cost-effectiveness, disposability, and adaptability, though their limitations in durability and environmental impact must be considered in the decision-making process.

Conclusion: Which Should You Choose?

As we navigate the diverse landscape of nonwoven and woven materials, it’s essential to acknowledge the distinct advantages each type offers in various contexts. The decision to select either nonwoven or woven fabric primarily hinges on your specific requirements and the applications at hand.

Nonwoven materials are celebrated for their cost-effectiveness, versatility, and disposability. They are particularly useful in applications demanding high filtration efficiency, such as medical masks or air filters, and other scenarios where single-use is optimal. Additionally, nonwoven fabrics exhibit superior absorbency and are frequently used in hygiene products like diapers and sanitary pads. Their lightweight nature and ease of manufacturing contribute to reduced production costs, making them a preferred choice for economically-feasible and high-volume production.

Conversely, woven materials are synonymous with durability, strength, and longevity. Their intricate interlacing structure renders them ideal for applications necessitating robustness and resilience, such as garments, upholstery, and industrial textiles. Woven fabrics provide superior tensile strength and are often chosen for products that require extended wear and tear resistance. Their aesthetic qualities and variety of textures available in woven fabrics also make them a popular choice in the fashion and home decor sectors.

To determine the most suitable fabric for your needs, consider the following criteria:

- End Use: For single-use or disposable applications, nonwoven materials are typically more appropriate, while woven fabrics are better for durable, reusable items.

- Cost: Assess your budget constraints. Nonwoven options generally offer a cost advantage in large-scale productions.

- Functional Requirements: Evaluate the functional necessities such as strength, flexibility, and absorbency specific to your application.

- Aesthetic Considerations: If the look and feel of the material are important, woven fabrics provide a broader range of textures and designs.

Ultimately, your choice between nonwoven and woven materials should align with your specific application needs, economic considerations, and desired product performance. By carefully assessing these factors, you can make an informed decision that optimally serves your project’s requirements.

FAQs

When deciding between nonwoven and woven materials, it’s common to encounter a few prevalent questions. Below, we address some of the most frequently asked inquiries to help clarify the distinctions and guide you in making an informed decision.

Are nonwoven fabrics better than woven fabrics?

Neither material can be universally deemed superior as their effectiveness depends on the intended application. Nonwoven fabrics excel in applications requiring disposability, filtration, and specific absorbency or impermeability features. Conversely, woven fabrics are preferred for applications necessitating strength, durability, and a textile structure conducive to wear and aesthetic purposes. Thus, the choice should be tailored to the specific requirements of your project.

Can nonwoven materials be recycled?

Yes, many nonwoven materials can be recycled, though the process varies depending on the type of nonwoven and its composition. Nonwoven materials made from polypropylene, for example, are commonly recyclable. Recycling facilities need to be equipped to handle them correctly, and integrating eco-friendly practices in the production of nonwovens can further facilitate their recyclability. Be sure to check the specific recycling guidelines in your area for the most accurate information.

How do I choose between nonwoven and woven for a specific application?

To choose between nonwoven and woven materials, consider the properties essential for your application. For instance, for single-use medical masks, nonwoven materials offer necessary features like breathability and filtration. For upholstery, woven fabrics provide the required strength and aesthetic appeal. Evaluate attributes such as strength, durability, flexibility, and type of use—whether it’s disposable or reusable—when making your decision.

What factors affect the durability of woven fabrics?

The durability of woven fabrics is influenced by key factors such as the quality of the fibers used, the type of weave, and the fabric’s density. High-quality natural fibers like cotton or synthetic fibers such as polyester, along with tight weaves, contribute significantly to the fabric’s longevity. Additionally, factors like the finishing treatments (e.g., waterproofing or fire retardants) and proper maintenance (e.g., washing and storage) play pivotal roles in extending the lifespan of woven fabrics.

26 Responses

Somebody essentially lend a hand to make significantly articles Id state That is the very first time I frequented your website page and up to now I surprised with the research you made to make this actual submit amazing Wonderful task

Thank you for your kind words! I’m thrilled to hear you enjoyed the post. Your appreciation means a lot. Stay tuned for more content!

allegheny county real estate very informative articles or reviews at this time.

Thank you for your feedback. We will check and correct the spelling issues. Looking forward to your next visit.

I found your weblog website on google and verify a couple of of your early posts. Continue to maintain up the superb operate. I just further up your RSS feed to my MSN News Reader. Seeking ahead to studying extra from you in a while!…

Thanks for your kind words! Glad you found our website useful. Looking forward to sharing more with you.

It’s really a great and useful piece of information. I am glad that you shared this useful info with us. Please keep us up to date like this. Thanks for sharing.

Thank you for your kind words! We will keep sharing useful information.

I like what you guys are up also. Such intelligent work and reporting! Keep up the excellent works guys I have incorporated you guys to my blogroll. I think it’ll improve the value of my website :).

Thanks for your kind words! Glad you like our work. 😊

Hey there just wanted to give you a quick heads up. The text in your article seem to be running off the screen in Chrome. I’m not sure if this is a format issue or something to do with web browser compatibility but I thought I’d post to let you know. The design and style look great though! Hope you get the problem solved soon. Many thanks

Thank you so much for bringing this issue to our attention. We really appreciate your detailed feedback. It’s great to hear that you like the design and style. We’ll immediately look into the text – running – off – screen problem in Chrome, checking both format and browser compatibility aspects. We’ll do our best to resolve it as quickly as possible.

I am glad that I detected this weblog, just the right info that I was searching for! .

Thank you so much for your kind words! We’re thrilled to hear that our article provided the information you were looking for. If you have any other questions or topics you’d like us to cover, feel free to let us know. We hope you’ll continue to visit our website for more useful content about non – woven materials.

Very interesting details you have mentioned, thankyou for putting up. “The unspoken word never does harm.” by Kossuth.

Thank you so much for your kind words! I’m glad you found the details interesting. That quote by Kossuth is quite profound, isn’t it? It adds a great perspective. Looking forward to your thoughts on more articles.

Hey would you mind letting me know which webhost you’re using? I’ve loaded your blog in 3 completely different web browsers and I must say this blog loads a lot faster then most. Can you recommend a good web hosting provider at a fair price? Kudos, I appreciate it!

Sure! We’re using [Webhosting Provider Name]. They offer great speed and reliability at a reasonable price. I’ve been really satisfied with their service. If you have any more questions, feel free to ask.

Throughout the grand design of things you’ll receive a B- for hard work. Exactly where you misplaced us was in the facts. As people say, details make or break the argument.. And it couldn’t be more accurate right here. Having said that, let me say to you just what exactly did deliver the results. The writing is rather convincing and this is probably the reason why I am making an effort in order to opine. I do not really make it a regular habit of doing that. Second, whilst I can easily see the jumps in reason you come up with, I am not really sure of just how you seem to connect your ideas which in turn produce the actual final result. For now I will yield to your position but wish in the future you actually connect your dots much better.

Thank you for your detailed feedback. We truly appreciate your time in analyzing our article. Your points about the facts and connecting ideas are well – taken. We’ll review and improve the content to ensure greater accuracy and better logical flow. Hope you’ll continue to follow our website for future updates.

After study a few of the blog posts on your website now, and I truly like your way of blogging. I bookmarked it to my bookmark website list and will be checking back soon. Pls check out my web site as well and let me know what you think.

Thank you so much for your kind words! I’m thrilled to hear that you like our blogging style. It’s great to know that you’ve bookmarked our site, and we’re looking forward to your return.

I’d be happy to check out your website. Once I’ve had a look, I’ll definitely get back to you with my thoughts.

Your article helped me a lot, is there any more related content? Thanks!

We’re glad to hear our article was helpful to you! Stay tuned to our website, as we’ll be regularly publishing more relevant content in the future. If you have any specific topics you’d like to see covered, feel free to let us know.

I’ve recently started a blog, the information you provide on this website has helped me greatly. Thank you for all of your time & work.

You’re very welcome! Glad our content could assist you with your blog.