Exploring the Intricacies of Nonwoven Hygiene Products: What You Need to Know

Outline

This article delves into the complexities of nonwoven hygiene products, providing a comprehensive guide for readers interested in understanding their various aspects.

1. Introduction to Nonwoven Hygiene Products

In this section, we define what nonwoven hygiene products are and highlight their significance in modern healthcare and daily life. We discuss the basic materials and technologies used in their production.

2. Types of Nonwoven Hygiene Products

Here, we categorize the different types of nonwoven hygiene products available, such as diapers, sanitary napkins, and medical face masks. Each category is briefly described with its primary uses and benefits.

3. Manufacturing Processes

This section provides an in-depth look at the various manufacturing processes involved in creating nonwoven hygiene products. It covers methods like spunbond, meltblown, and hydroentanglement, explaining their unique characterist

4.Common Applications

This text refers to the common applications of nonwoven hygiene products. Nonwoven hygiene products have a wide range of uses in healthcare and daily life. These products include but are not limited to sanitary pads, diapers, and medical masks. They play an important role in maintaining personal hygiene, preventing infections, and enhancing comfort.

5. Benefits of Nonwoven Hygiene Products

We explore the numerous advantages of using nonwoven hygiene products, including their cost-effectiveness, high absorbency, and skin-friendliness. This section also compares them to traditional woven products to highlight their superior qualities.

6. Challenges and Concerns

In this section, we will discuss the potential challenges and concerns that may arise.

6. Innovations and Future Trends

In this section, we analyze current market trends and recent innovations in the nonwoven hygiene product sector. Topics include advancements in materials, emerging technologies, and shifts in consumer preferences.

7. Common FAQ

1.Introduction to Nonwoven Hygiene Products

Nonwoven hygiene products are essential items in both medical and personal care contexts, known for their versatility and efficiency. These products are made from fibers that are bonded together through various processes such as mechanical, thermal, or chemical methods, without weaving or knitting. This unique production technique results in a fabric that is dense, durable, and highly absorbent, distinguishing nonwoven materials from traditional woven fabrics.

The composition of nonwoven hygiene products typically includes synthetic fibers like polypropylene and polyethylene, or natural fibers such as cotton. These fibers can be engineered to meet specific requirements, offering a range of properties like softness, strength, and liquid repellency. The flexibility in the choice of raw materials and manufacturing processes allows for the creation of products tailored to different hygiene needs, such as diapers, sanitary napkins, adult incontinence products, and medical dressings.

One of the key characteristics of nonwoven hygiene products is their ability to provide a sterile barrier, which is crucial in medical environments. For instance, surgical masks, gowns, and drapes are often made from nonwoven fabrics to ensure high levels of protection against infections. In personal care, their high absorbency and softness make them ideal for use in products that require intimate contact with the skin, ensuring comfort and hygiene.

The importance of nonwoven hygiene products in everyday life cannot be overstated. They play a critical role in maintaining health and sanitation, offering practical solutions for managing bodily fluids, protecting against contaminants, and providing comfort. Their widespread use in both medical and personal care sectors highlights their significance and the ongoing demand for innovation in the nonwoven fabric industry.

2. Types of Nonwoven Hygiene Products

Nonwoven hygiene products refer to a variety of personal care items that are made from nonwoven materials. These materials are engineered fabrics that are created by bonding or interlocking fibers together, rather than weaving or knitting them. Nonwoven hygiene products are designed to provide comfort, absorbency, and protection for the user.

There are several types of nonwoven hygiene products, including:

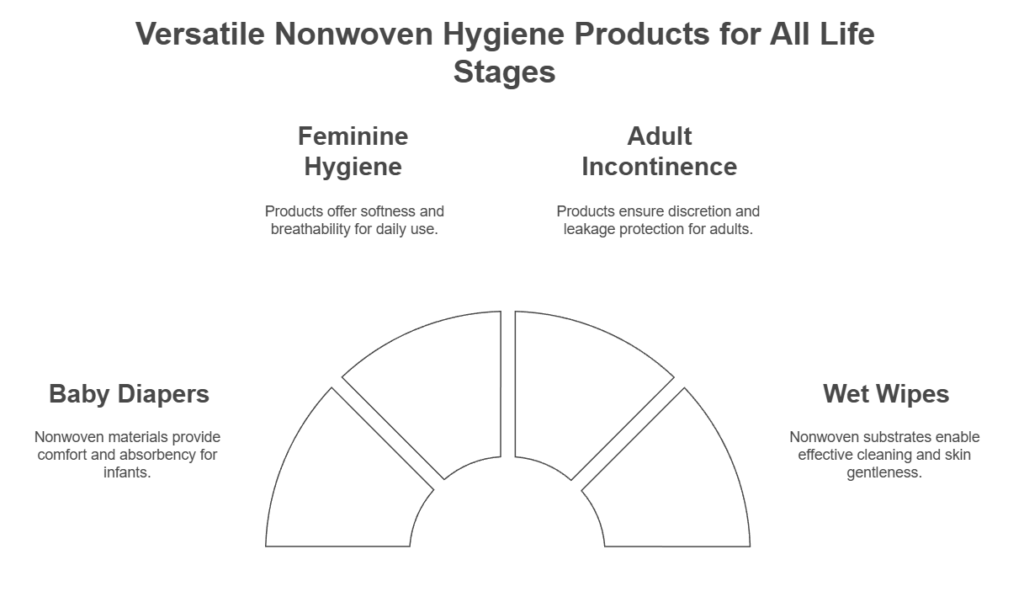

- Baby diapers: Nonwoven materials are commonly used in the construction of disposable baby diapers. These materials provide a soft and comfortable feel against the baby’s skin, while also offering excellent absorbency to keep the baby dry and comfortable.

- Feminine hygiene products: Nonwoven materials are also used in the production of feminine hygiene products such as sanitary pads and panty liners. These materials provide a soft and breathable layer that helps to keep the user feeling dry and comfortable throughout the day.

- Adult incontinence products: Nonwoven materials are often used in the construction of adult incontinence products such as disposable underwear and pads. These materials offer excellent absorbency and leakage protection, while also providing a comfortable and discreet fit for the user.

- Wet wipes: Nonwoven materials are commonly used in the production of wet wipes, which are used for personal hygiene, baby care, and household cleaning. These materials provide a soft and durable substrate for the wet wipe solution, allowing for effective cleaning and gentle use on the skin.

Overall, nonwoven hygiene products play a crucial role in providing comfort, protection, and convenience for individuals of all ages. Their use of nonwoven materials ensures that they are soft, absorbent, and comfortable for everyday use.

The Manufacturing Process

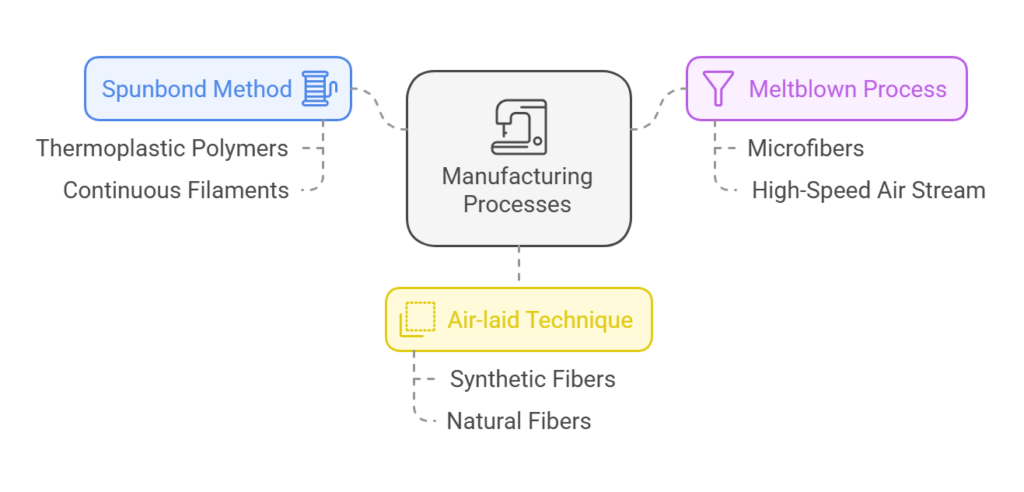

The manufacturing process of nonwoven hygiene products is intricate, involving several sophisticated methods to produce materials that meet stringent quality and performance standards. One of the primary techniques utilized is the spunbond method, where thermoplastic polymers like polypropylene are melted and extruded through fine nozzles to form continuous filaments. These filaments are then laid randomly on a conveyor belt and bonded together using heat or chemical processes, resulting in a strong and durable fabric.

Another critical method is the meltblown process, which also begins with melting thermoplastic polymers. However, in this technique, the molten polymer is extruded through a high-speed air stream that breaks it into microfibers. These microfibers are collected on a rotating drum or belt to form a web-like structure. The fine fibers produced through the meltblown process are particularly effective for applications requiring high filtration efficiency, such as in medical masks and sanitary napkins.

The air-laid technique is yet another pivotal method in the production of nonwoven hygiene products. In air-laid processes, fibers—either synthetic like polypropylene or natural like cotton—are dispersed in an air stream and then condensed onto a moving belt to form a web. This web is subsequently bonded using heat, pressure, or adhesives. The air-laid method is especially valued for producing soft, absorbent layers utilized in products like baby diapers and incontinence pads.

The choice of raw materials profoundly impacts the quality and functionality of the final nonwoven product. Synthetic fibers like polypropylene are favored for their durability, water resistance, and cost-effectiveness. In contrast, natural fibers like cotton are chosen for their softness and breathability. Each material and method plays a crucial role in ensuring the nonwoven hygiene products meet the required standards for comfort, absorbency, and safety, ultimately enhancing consumer satisfaction.

Common Applications

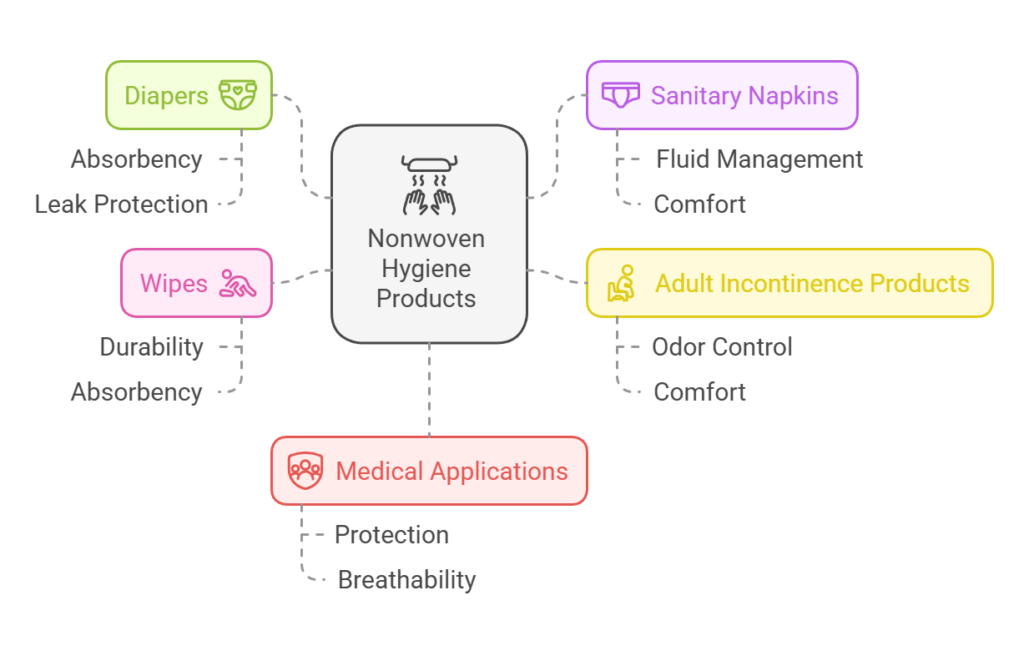

Nonwoven hygiene products have seen widespread adoption across various sectors due to their unique properties, including absorbency, softness, and breathability. One of the most prevalent applications is in the production of diapers. Nonwoven fabrics provide the essential qualities needed for baby diapers, such as high absorption, leak protection, and skin-friendliness. According to a report by MarketsandMarkets, the global diaper market is projected to reach USD 79.1 billion by 2025, underscoring the significant role of nonwoven materials in this industry.

Sanitary napkins are another critical application of nonwoven materials. These products require materials that can offer superior fluid management and comfort, making nonwovens an ideal choice. The global sanitary napkin market size was valued at USD 20.62 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 4.8% from 2021 to 2028, as per Grand View Research.

Adult incontinence products also benefit from the properties of nonwoven fabrics. These products, designed for individuals dealing with incontinence, demand high absorbency, odor control, and comfort. Nonwoven materials meet these requirements effectively, contributing to the growing market, which is anticipated to reach USD 24.2 billion by 2027, according to Allied Market Research.

Wipes, both consumer and industrial, are another significant application of nonwoven materials. These products range from baby wipes to industrial cleaning wipes and rely on the durability, absorbency, and disposability of nonwoven fabrics. The global nonwoven wipes market is expected to grow, driven by increasing demand for personal hygiene and cleanliness.

In the medical field, nonwoven materials are extensively used in protective gear such as surgical masks, gowns, and drapes. The COVID-19 pandemic highlighted the importance of nonwoven materials in healthcare settings, leading to increased production and innovation. Nonwoven fabrics provide the necessary protection against pathogens while being lightweight and breathable, making them indispensable in medical applications.

Overall, the versatility and functional benefits of nonwoven materials have cemented their place in various hygiene products, driving market growth and innovation across multiple sectors.

Benefits of Nonwoven Hygiene Products

Nonwoven hygiene products have garnered significant attention due to their numerous advantages over traditional woven materials. A primary benefit of nonwoven materials is their exceptional absorbency. These materials are engineered to quickly and efficiently absorb liquids, making them ideal for products such as diapers, sanitary napkins, and wipes. The highly absorbent nature ensures that users remain dry and comfortable, thereby enhancing the overall user experience.

Another critical advantage of nonwoven hygiene products is their breathability. Nonwoven fabrics are designed to allow air to circulate while blocking moisture and contaminants. This breathability helps to maintain a healthy and comfortable environment for the skin, reducing the risk of irritation and infections. In contrast, traditional woven materials often trap heat and moisture, leading to discomfort and potential skin issues.

Softness is yet another notable attribute of nonwoven materials. The manufacturing process allows for the creation of fabrics that are gentle and soft against the skin, making them perfect for sensitive areas. This softness is a significant improvement over many woven materials, which can sometimes be rough and abrasive.

Cost-effectiveness is an essential consideration for both manufacturers and consumers. Nonwoven materials are generally more economical to produce than woven fabrics. The efficient production process and the ability to create large quantities quickly contribute to their lower cost. This cost advantage makes nonwoven hygiene products accessible to a broader audience, without compromising on quality.

Environmental benefits also play a crucial role in the appeal of nonwoven hygiene products. Many nonwoven materials are designed to be biodegradable or recyclable, reducing their environmental footprint. This aspect is particularly important in today’s eco-conscious society, where sustainability is a key concern.

When comparing nonwoven materials to traditional woven fabrics and other alternatives, it is evident that nonwoven hygiene products offer superior performance in terms of absorbency, breathability, softness, cost-effectiveness, and environmental impact. These benefits make nonwoven materials a preferred choice for a wide range of hygiene applications, providing comfort, efficiency, and sustainability.

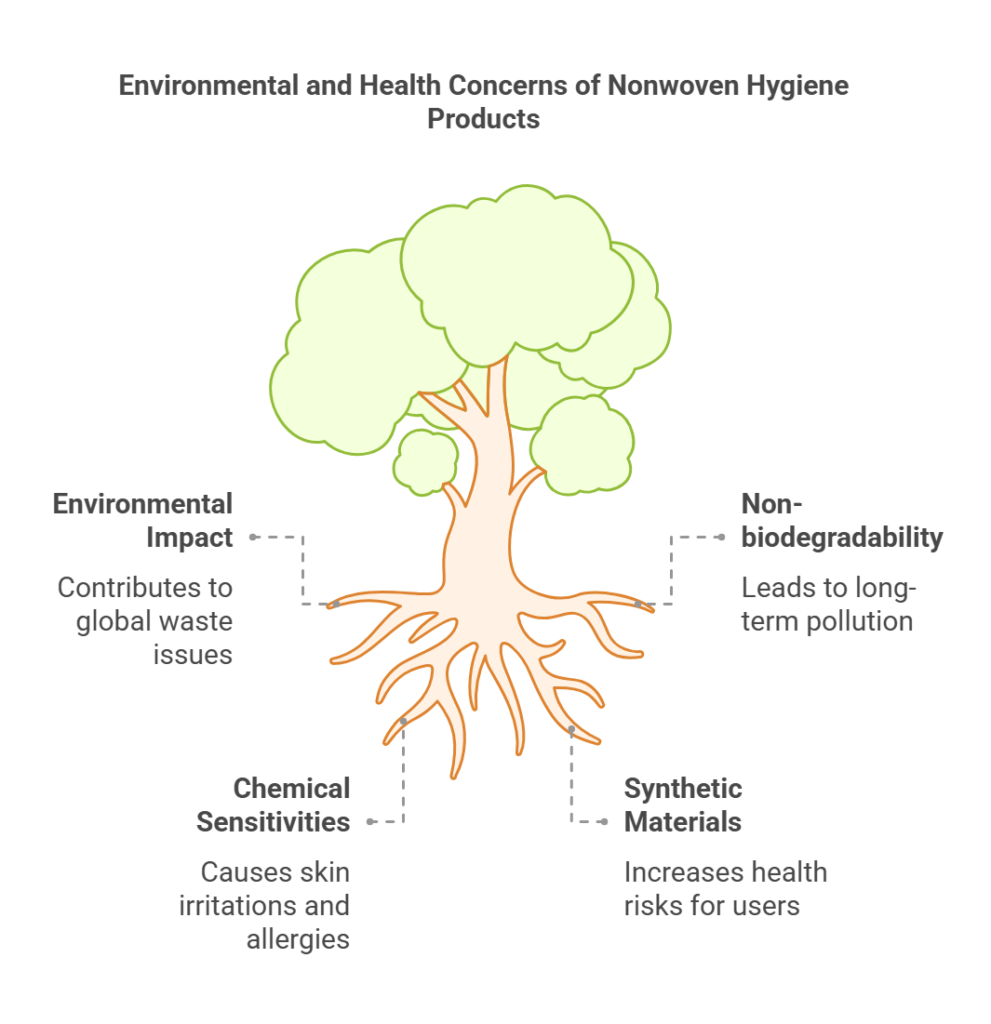

Challenges and Concerns

Nonwoven hygiene products, while offering considerable benefits in terms of convenience and hygiene, are not without their challenges and concerns. One of the primary issues revolves around their environmental impact. Due to the synthetic materials often used in these products, they contribute significantly to waste, posing a challenge for waste management systems globally. The biodegradability of nonwoven hygiene products is a significant concern, as many of these products do not decompose easily, leading to long-term environmental pollution.

In addition to environmental concerns, health issues such as skin irritations and allergies are also associated with nonwoven hygiene products. Some individuals may experience adverse reactions due to the chemicals and synthetic fibers used in the production of these items. These reactions can range from mild irritations to severe allergic responses, impacting the overall usability and safety of these products.

However, ongoing research and developments are actively addressing these challenges. Innovations in the production of nonwoven hygiene products are focusing on the use of biodegradable and eco-friendly materials. Researchers are exploring natural fibers and advanced manufacturing techniques to create products that are both effective and environmentally sustainable. Additionally, there is a concerted effort to develop hypoallergenic nonwoven hygiene products, reducing the risk of skin irritations and allergic reactions. These advancements are promising and indicate a future where nonwoven hygiene products can be used with greater confidence, both for personal health and environmental sustainability.

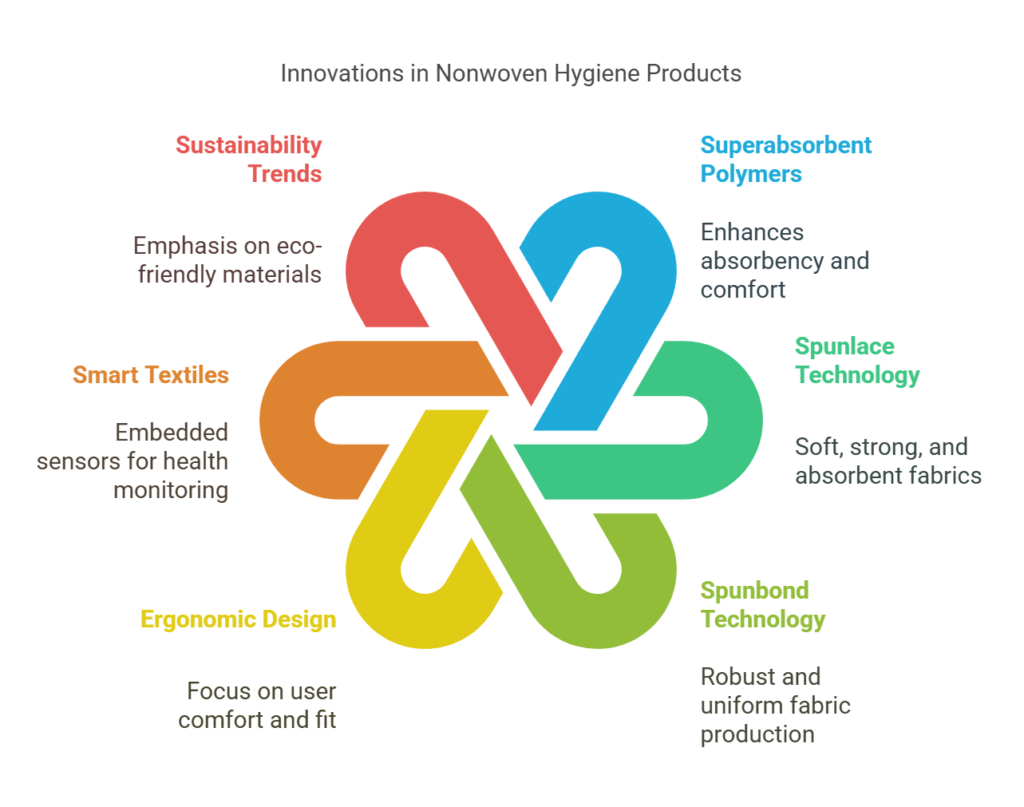

Innovations and Future Trends

The landscape of nonwoven hygiene products is continually evolving, driven by significant innovations in materials, production techniques, and product design. One of the standout advancements is the development of superabsorbent polymers (SAPs) that enhance the absorbency and comfort of products such as diapers and sanitary pads. These polymers are engineered to absorb and retain large quantities of liquid, thereby ensuring dryness and minimizing the risk of skin irritation.

Another crucial innovation is the use of spunlace and spunbond technologies, which have revolutionized the manufacturing process of nonwoven fabrics. Spunlace technology, for example, involves entangling fibers using high-pressure water jets, resulting in a fabric that is soft, strong, and highly absorbent. On the other hand, spunbond technology employs continuous filaments, creating a robust and uniform fabric that is ideal for hygiene applications.

Product design has also witnessed transformative changes. Manufacturers are increasingly focusing on ergonomics and user comfort. For instance, the advent of 3D printing technology has enabled the creation of ergonomically designed hygiene products that offer a better fit and enhanced functionality. Additionally, smart textiles embedded with sensors are being developed to monitor health indicators, such as hydration levels and skin conditions, providing real-time data for personalized care.

Looking ahead, the trend towards sustainability is poised to shape the future of nonwoven hygiene products. There is a growing emphasis on using biodegradable and recyclable materials to reduce the environmental impact. Innovations in bio-based polymers, derived from renewable resources like corn starch and sugarcane, are gaining traction. These materials not only offer comparable performance to traditional synthetics but also significantly lower the carbon footprint.

Industry experts predict that the demand for eco-friendly hygiene products will continue to rise, driven by consumer awareness and regulatory pressures. Recent market research indicates that consumers are increasingly prioritizing sustainability and are willing to pay a premium for products that align with their environmental values. This shift is prompting manufacturers to invest in green technologies and adopt circular economy principles, ensuring that products are designed for reuse, recycling, and minimal waste.

In conclusion, the nonwoven hygiene products sector is on the cusp of a transformative era marked by groundbreaking innovations and a steadfast commitment to sustainability. As these trends unfold, they will not only enhance product performance and user experience but also contribute to a more sustainable and eco-friendly future.

FAQs

How do I choose the right nonwoven hygiene product?

Choosing the right nonwoven hygiene product depends on the specific needs of the user. Consider factors such as absorbency level, size, material composition, and skin sensitivity. Reading product labels and reviews can also provide valuable insights.

What are the different types of nonwoven materials used in hygiene products?

Various nonwoven materials are used in hygiene products, including spunbond, meltblown, and spunlace. Each type has different properties: spunbond offers strength and durability, meltblown provides high absorbency, and spunlace combines softness and flexibility.

Are nonwoven hygiene products safe for sensitive skin?

Many nonwoven hygiene products are designed with sensitive skin in mind. Look for products labeled as hypoallergenic or dermatologically tested to ensure they are safe for sensitive skin. Always perform a patch test if you are unsure.

Can nonwoven hygiene products be recycled?

Recycling nonwoven hygiene products can be challenging due to contamination and material composition. However, some manufacturers are developing eco-friendly, biodegradable options. Check with local recycling programs for specific guidelines.

What are the benefits of using nonwoven hygiene products?

Nonwoven hygiene products offer several benefits, including high absorbency, softness, breathability, and lightweight properties. They are also designed for single-use, reducing the risk of infection and ensuring hygiene.

How should I dispose of nonwoven hygiene products?

Proper disposal of nonwoven hygiene products is crucial for maintaining hygiene and protecting the environment. Dispose of these products in a designated waste bin, and avoid flushing them down the toilet to prevent blockages and environmental harm.

Are there any tips for using nonwoven hygiene products effectively?

To use nonwoven hygiene products effectively, follow the manufacturer’s instructions for application and disposal. Ensure the product is properly positioned for maximum absorbency and comfort. Regularly change the product as needed to maintain hygiene.