Exploring the World of Nonwoven Fabric: Uses, Benefits, and Production Techniques

Introduction

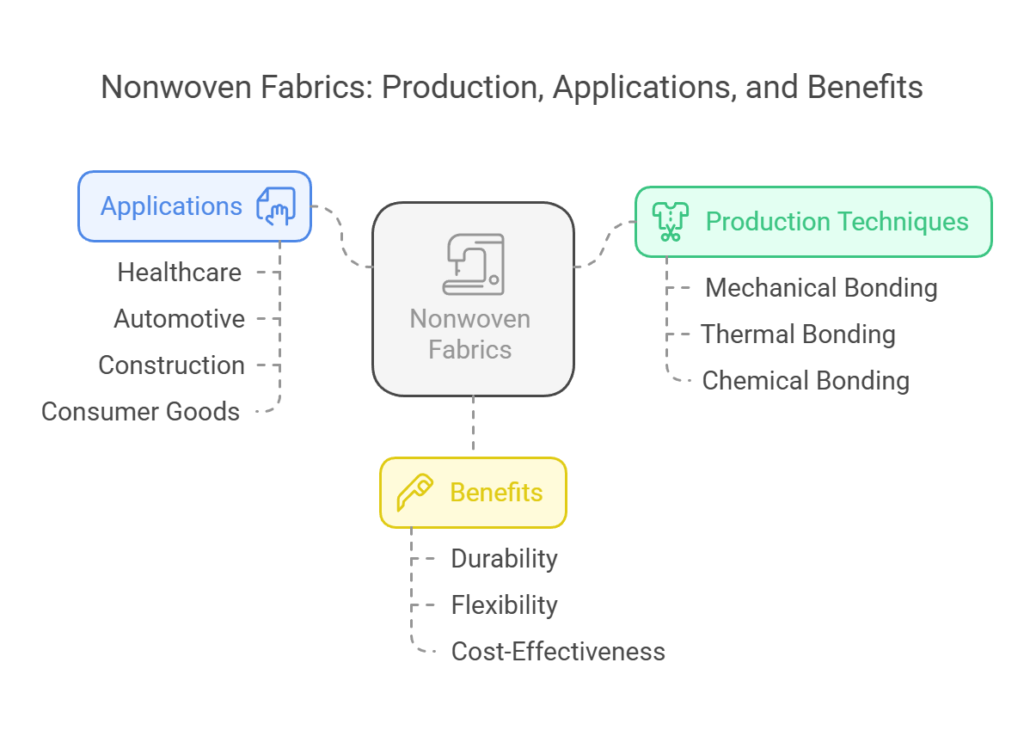

Nonwoven fabric represents a unique class of textile material that is distinct from traditional woven and knitted fabrics. Unlike woven fabrics, which are created through the interlacing of yarns, or knitted fabrics, formed by interlooping yarns, nonwoven fabrics are made by bonding fibers together through various methods such as mechanical, thermal, or chemical processes. This bonding creates a network of fibers that can be engineered to achieve specific properties and functionalities, making nonwoven fabrics highly versatile and adaptable.

The origins of nonwoven fabric can be traced back to the mid-20th century, when innovations in textile manufacturing began to explore alternatives to conventional fabric production methods. The first nonwoven fabrics were developed in the 1940s, primarily for use in disposable products like wipes and medical dressings. Over time, advancements in technology and materials science have significantly expanded the range of applications for nonwovens, leading to their widespread adoption in numerous industries.

Today, nonwoven fabrics are integral to various sectors, including healthcare, automotive, construction, and consumer goods. For example, in the healthcare industry, nonwovens are used to produce surgical gowns, masks, and sterile packaging. In the automotive sector, they serve as components in interior linings and filters. The construction industry utilizes nonwovens for geotextiles and insulation materials, while consumer goods often feature nonwoven fabrics in products such as diapers, sanitary napkins, and cleaning wipes.

The growing importance of nonwoven fabrics can be attributed to their unique properties, including durability, flexibility, and cost-effectiveness. Additionally, nonwovens offer the advantage of being customizable to meet specific requirements, such as varying levels of absorbency, strength, and breathability. As industries continue to demand innovative and efficient materials, the relevance of nonwoven fabrics is expected to increase, driving further advancements and applications in the years to come.

Types of Nonwoven Fabrics

Nonwoven fabrics represent a versatile and essential segment of the textile industry. Their diverse applications stem from the various types of nonwoven fabrics available, each possessing unique properties and production processes. Three primary types of nonwoven fabrics include spunbond, meltblown, and needle-punched. This section delves into the specifics of these types, elaborating on their creation processes, characteristics, and the materials used in their production.

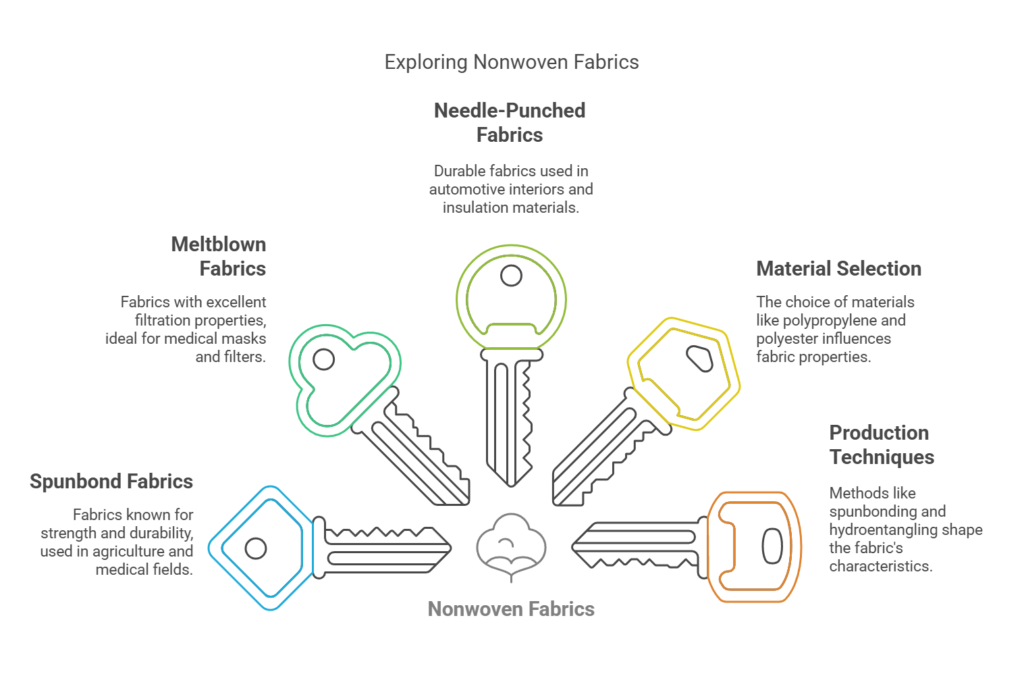

Spunbond Nonwoven Fabric: Spunbond nonwoven fabric is produced by extruding thermoplastic polymers, such as polypropylene, polyester, or polyethylene, through a spinneret to create continuous filaments. These filaments are laid randomly onto a conveyer belt to form a web, which is then bonded together through heat, chemical, or mechanical processes. Spunbond fabrics are known for their strength, durability, and breathability, making them ideal for applications such as agricultural covers, medical textiles, and geotextiles.

Meltblown Nonwoven Fabric: Meltblown nonwoven fabric is generated by extruding molten polymer through tiny nozzles surrounded by high-speed blowing gas. This process transforms the polymer into microfibers, which are collected on a conveyor belt to form a web. The resulting fabric is characterized by its fine fibers, high surface area, and excellent filtration properties. Common materials used in meltblown production include polypropylene and polyester. Meltblown fabrics are particularly effective in medical masks, air and liquid filtration systems, and absorbent products.

Needle-Punched Nonwoven Fabric: Needle-punched nonwoven fabric is created through a mechanical process in which barbed needles are repeatedly punched through a web of fibers. This action entangles the fibers, creating a cohesive and robust fabric. Needle-punched fabrics can be made from a variety of fibers, including synthetic options like polypropylene and polyester, as well as natural fibers like wool and cotton. These fabrics offer excellent durability and are often employed in applications such as automotive interiors, carpeting, and insulation materials.

The choice of materials plays a crucial role in determining the properties of nonwoven fabrics. Commonly used materials include polypropylene, known for its chemical resistance and low cost; polyester, valued for its strength and resilience; and rayon, appreciated for its softness and absorbency. The selection of material directly influences the fabric’s suitability for specific applications, ensuring that nonwoven fabrics can meet diverse industry needs.

Nonwoven fabric production encompasses several sophisticated techniques, each contributing uniquely to the material’s properties and applications. Among the most prominent methods are spunbonding, meltblowing, and hydroentangling, each with distinct processes and benefits.

Spunbonding

Spunbonding involves the extrusion of thermoplastic polymers, primarily polypropylene, through fine spinnerets to form continuous filaments. These filaments are then laid randomly on a conveyor belt and bonded together using thermal, mechanical, or chemical means. The resulting fabric is characterized by its high strength, durability, and uniformity. Spunbonded nonwoven fabrics find extensive use in geotextiles, medical gowns, and agricultural coverings. However, the requirement for high initial investment in machinery can be a drawback for some manufacturers.

Meltblowing

Meltblowing is another critical technique in nonwoven fabric production. It involves extruding molten polymer through a linear die containing hundreds of small orifices. Concurrently, high-velocity hot air blows the extruded fibers into a fine, randomly distributed web. Meltblown fabrics are known for their excellent filtration properties, making them ideal for medical masks, air filters, and insulation materials. While offering high porosity and fine fiber diameter, the meltblowing process can be energy-intensive and may require precise control of processing parameters to achieve the desired fabric characteristics.

Hydroentangling

Hydroentangling, or spunlacing, is a non-thermal bonding process that uses high-pressure water jets to entangle fibers and form a cohesive fabric. This technique is versatile, allowing the use of various raw materials, including natural and synthetic fibers. The resultant nonwoven fabrics exhibit softness, flexibility, and high absorbency, suitable for applications in wipes, medical dressings, and hygiene products. One of the notable advantages of hydroentangling is the ability to produce fabrics without the need for binders or adhesives. However, the process requires significant amounts of water and energy, which can impact production costs and environmental sustainability.

Technological advancements continuously refine these production techniques, enhancing efficiency, reducing environmental impact, and expanding the capabilities of nonwoven fabrics. Innovations such as bi-component fibers, nanofiber production, and automation in manufacturing processes are paving the way for the next generation of nonwoven materials, offering even greater performance and versatility.

Applications of Nonwoven Fabrics

Nonwoven fabrics have garnered significant attention across various industries due to their versatility and unique properties. One of the most prominent applications of nonwoven fabrics is in the healthcare sector. These materials are vital in the production of surgical masks, gowns, drapes, and other medical supplies. The inherent breathability, lightweight nature, and high filtration efficiency of nonwoven fabrics make them ideal for preventing contamination and ensuring patient safety during medical procedures.

In the automotive industry, nonwoven fabrics play a crucial role in enhancing vehicle performance and passenger comfort. They are commonly used for interior components such as insulation, headliners, and upholstery. These fabrics provide excellent noise reduction, thermal insulation, and durability, contributing to a quieter and more comfortable driving experience. Additionally, their lightweight characteristic helps in reducing the overall weight of the vehicle, leading to improved fuel efficiency.

The construction industry also benefits significantly from the use of nonwoven fabrics, particularly in the form of geotextiles. Geotextiles are used for soil stabilization, erosion control, and drainage systems. They offer superior strength, permeability, and resistance to environmental factors, making them essential for various civil engineering projects. Nonwoven geotextiles help extend the lifespan of infrastructure by providing robust support and enhancing the stability of soil structures.

Consumer products constitute another major domain where nonwoven fabrics are extensively employed. Items such as wipes, diapers, and feminine hygiene products rely on the absorbent properties and softness of nonwoven materials. These fabrics ensure high levels of comfort and hygiene, making them indispensable in everyday life. Their ability to be engineered for specific functionalities, such as enhanced absorbency or antimicrobial properties, further underscores their utility in consumer goods.

Overall, the applications of nonwoven fabrics span a wide range of industries, highlighting their adaptability and effectiveness in meeting diverse requirements. From medical safety to automotive innovation and construction resilience to everyday consumer convenience, nonwoven fabrics continue to offer significant advantages, reinforcing their pivotal role in modern industry.

Advantages of Nonwoven Fabrics

Nonwoven fabrics offer numerous advantages that make them a preferred choice in various industries. One of the foremost benefits is cost-effectiveness. The simplicity of production processes, which often involve bonding fibers together through mechanical, chemical, or thermal methods, minimizes manufacturing costs. This makes nonwoven fabrics an economical alternative to traditional woven and knitted textiles.

Versatility is another significant advantage of nonwoven fabrics. These materials can be engineered to meet specific performance requirements, making them suitable for a wide range of applications. For instance, nonwoven fabrics can be designed to possess high durability, making them ideal for use in products that require longevity. Similarly, they can be made highly absorbent, which is beneficial for applications in medical and hygiene products, such as diapers and surgical gowns. Additionally, the filtration efficiency of nonwoven fabrics can be tailored to meet stringent standards, making them essential in air and water filtration systems.

Environmental benefits of nonwoven fabrics also contribute to their growing popularity. Many nonwoven materials are recyclable and biodegradable, which helps reduce the environmental footprint. The ease of recycling nonwoven fabrics stems from their single-material composition, allowing for straightforward reprocessing. Moreover, advancements in biodegradable nonwoven fabrics have paved the way for eco-friendly products that break down naturally, reducing landfill waste.

Furthermore, nonwoven fabrics exhibit unique properties that enhance their functionality. For instance, they can be engineered to provide specific tactile qualities, such as softness or stiffness, depending on the application. This adaptability extends to their ability to incorporate additives that impart characteristics like flame retardancy or antimicrobial properties, broadening their utility across different sectors.

In summary, the cost-effectiveness, versatility, and environmental benefits make nonwoven fabrics an advantageous choice for a multitude of applications. Their ability to be tailored to specific performance requirements ensures that they can meet the diverse needs of various industries, from healthcare to environmental management.

Challenges and Limitations

While nonwoven fabrics offer a myriad of benefits, they are not without their challenges and limitations. One significant concern is durability. Unlike woven fabrics, nonwoven materials often exhibit limited strength and longevity. This can result in a shorter lifespan for products made from nonwoven fabrics, making them less suitable for applications that require long-term durability and repeated use. For instance, certain nonwoven fabrics may tear or wear out more quickly under stress or friction, which is a notable drawback compared to their woven counterparts.

Another critical issue is the environmental impact. Nonwoven fabrics, particularly those made from synthetic fibers like polypropylene, contribute to plastic pollution. The lack of biodegradability in these materials poses a significant environmental challenge, as they can persist in ecosystems for extended periods. Additionally, the production process of nonwoven fabrics can also be resource-intensive, involving the use of chemicals and large amounts of energy, which further exacerbates their ecological footprint.

Cost is another limiting factor. While nonwoven fabrics can be economically advantageous for specific applications, high-quality nonwoven materials can be expensive to produce. The cost is often driven by the need for specialized machinery and processes, as well as the price of raw materials. This can make nonwoven fabrics less competitive compared to traditional woven fabrics, especially in industries where cost efficiency is paramount.

Despite these limitations, ongoing research and technological advancements aim to address these challenges. Innovations in material science are leading to the development of stronger, more durable nonwoven fabrics. Efforts are also being made to create biodegradable and eco-friendly nonwoven materials, which can mitigate the environmental impact. Additionally, advancements in production techniques are helping to reduce costs, making nonwoven fabrics more accessible and sustainable.

In sum, while nonwoven fabrics face several challenges related to durability, environmental impact, and cost, ongoing research and innovation continue to provide promising solutions. By addressing these limitations, the potential for nonwoven fabrics in various applications can be significantly enhanced.

Future Trends and Innovations

The nonwoven fabric industry is poised for significant advancements, driven by emerging technologies and a heightened focus on sustainability. One such technology making waves is nanofiber production. Nanofibers, characterized by their extremely small diameter, offer superior filtration capabilities and are being increasingly utilized in medical applications, air and water filtration systems, and advanced textiles. The precision and efficiency of nanofiber production techniques promise to revolutionize the performance and application range of nonwoven fabrics.

Sustainable manufacturing practices are another critical area of development. The industry is moving towards the use of biodegradable and recyclable materials, aiming to reduce the environmental impact of nonwoven fabrics. Innovations such as the use of bio-based polymers and eco-friendly bonding techniques are gaining traction. These practices not only address environmental concerns but also cater to the growing consumer demand for sustainable products.

Market growth projections for nonwoven fabrics remain highly optimistic. According to industry experts, the global nonwoven fabric market is expected to reach unprecedented heights in the coming years. This growth is fueled by the increasing demand in healthcare, hygiene, automotive, and construction sectors. The versatility and adaptability of nonwoven fabrics make them ideal for a variety of applications, from personal protective equipment to geotextiles and automotive interiors.

New applications for nonwoven fabrics are continuously being explored. Advances in material science and engineering are enabling the development of nonwoven fabrics with enhanced properties such as increased durability, improved barrier performance, and greater comfort. These innovations are opening up new possibilities in sectors like fashion, sportswear, and even smart textiles, where nonwoven fabrics can be integrated with electronic components for added functionality.

Insights from industry leaders suggest that the future of nonwoven fabrics will be marked by ongoing innovation and adaptation. Companies are investing heavily in research and development to stay ahead of the curve, focusing on creating high-performance, eco-friendly nonwoven solutions. As technology continues to evolve, the potential for nonwoven fabrics to transform industries and improve quality of life becomes ever more apparent.

Conclusion and Final Thoughts

Throughout this blog post, we have delved into the multifaceted world of nonwoven fabric, uncovering its myriad applications, significant benefits, and the sophisticated production techniques that underpin its manufacture. Nonwoven fabrics have cemented their place across diverse industries—ranging from healthcare to automotive, and from agriculture to fashion—thanks to their unique properties such as durability, breathability, and cost-effectiveness.

The importance of nonwoven fabrics in contemporary society cannot be overstated. Their versatility allows them to meet the ever-evolving demands of various sectors, offering innovative solutions that traditional woven materials often cannot provide. The adaptability of these fabrics plays a crucial role in their widespread adoption and underscores their potential for future applications.

Moreover, the continuous advancements in the technology and production methods of nonwoven fabrics are paving the way for new and improved materials. Innovations in this field promise to enhance the performance, sustainability, and affordability of nonwoven products, making them even more integral to modern life. As research and development in nonwoven fabric technology persist, the potential for groundbreaking discoveries and applications only grows.

We encourage readers to stay informed about the latest advancements in nonwoven fabric technology and explore the burgeoning opportunities within this dynamic industry. Whether you are a manufacturer, designer, or simply someone with a keen interest in material science, there is much to gain from keeping abreast of the latest trends and innovations in nonwoven fabrics. By doing so, you can contribute to the ongoing growth and development of this vital sector, ensuring that it continues to meet the needs of future generations.

One Response

You have remarked very interesting points! ps

nice internet site.Expand blog