What Are the Key Elements of Nonwoven Bag Design?

Introduction:

What are the essential elements to consider in the design of nonwoven bags? This fundamental question serves as the cornerstone of our exploration into the intricacies of nonwoven bag design. Nonwoven bags, renowned for their environmental benefits and versatility, have become a staple in various industries, from retail to promotional events. Yet, what makes a nonwoven bag not just functional but also appealing and effective? Understanding the key components that contribute to a well-designed nonwoven bag is crucial for manufacturers, designers, and consumers alike.

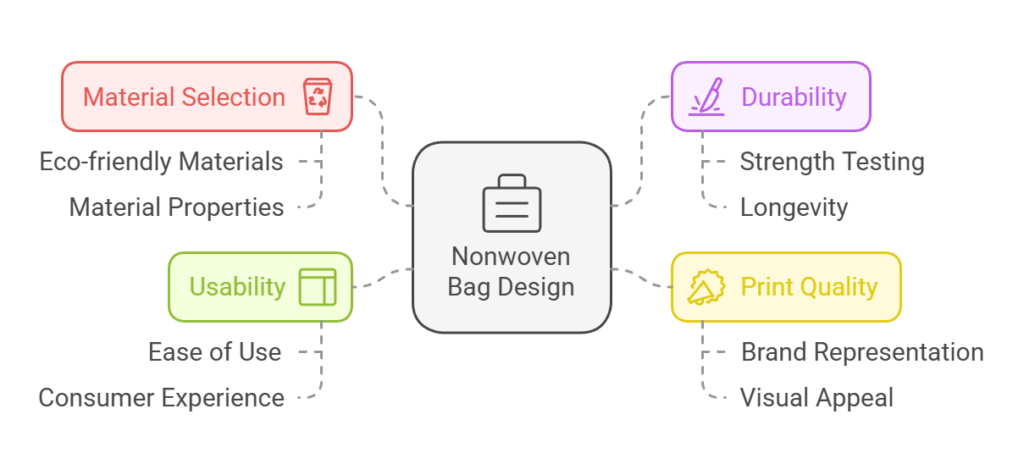

In an era where sustainability and innovation are paramount, the design of nonwoven bags holds significant importance. These bags are not merely utilitarian items; they also serve as a medium for brand representation and environmental advocacy. Therefore, delving into the critical aspects of their design, such as material selection, durability, print quality, and usability, can shed light on what sets high-quality nonwoven bags apart from the rest. Our aim is to dissect these elements meticulously, providing a comprehensive guide for those looking to either produce or utilize these eco-friendly alternatives effectively.

As we embark on this detailed examination, we will address a variety of factors that influence the overall quality and functionality of nonwoven bags. By posing the question of what constitutes an ideal nonwoven bag design, we invite readers to consider the broader implications of their choices. Whether you are a seasoned designer, a business owner looking to make informed purchasing decisions, or an environmentally conscious consumer, understanding these elements can significantly impact your approach to nonwoven bags. Let us begin this journey by exploring each critical component in detail, ensuring a thorough and insightful discussion on the art and science of nonwoven bag design.

Answer to the Question

Nonwoven bag design is a multifaceted process that involves several key elements to ensure the final product meets both aesthetic and functional requirements. At the forefront of this process is material selection. Nonwoven fabrics are chosen for their strength, versatility, and cost-effectiveness. These materials, which include polypropylene and polyester, are lightweight yet durable, offering a balance between affordability and longevity.

Durability is another critical factor in the design of nonwoven bags. The selected materials must be able to withstand repeated use and substantial loads without compromising their structural integrity. This is typically achieved through reinforced stitching, high-quality fabric treatments, and thoughtful design considerations that distribute weight evenly.

The environmental impact of nonwoven bags is a significant consideration in modern design practices. Unlike single-use plastic bags, nonwoven bags are reusable and recyclable, which significantly reduces their ecological footprint. Designers often opt for eco-friendly materials and manufacturing processes to align with sustainable practices. This includes the use of recycled fibers and non-toxic dyes.

Design aesthetics play a pivotal role in the appeal of nonwoven bags. These bags must not only be functional but also visually appealing to attract consumers. This involves careful consideration of colors, patterns, and branding elements. Customization options such as printing logos or slogans can enhance the bag’s marketability and serve as a mobile advertisement.

Lastly, functionality is paramount in nonwoven bag design. The bag must meet the specific needs of its intended use. This includes appropriate sizing, handle design, and additional features like pockets or closures. A well-designed nonwoven bag will seamlessly integrate these elements to provide a product that is both practical and user-friendly.

In summary, the design of nonwoven bags involves a careful balance of material selection, durability, environmental considerations, aesthetics, and functionality. Each of these elements is crucial in creating a product that not only meets consumer demands but also promotes sustainability.

Material Selection for Nonwoven Bags

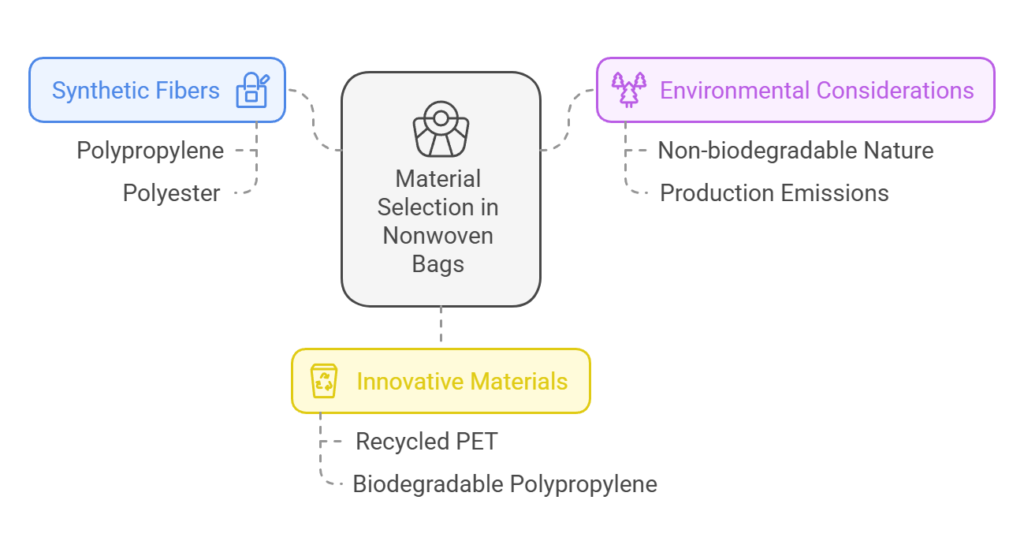

Material selection is a foundational element in the design of nonwoven bags, directly impacting their functionality, durability, and environmental footprint. Nonwoven bags are typically crafted from synthetic fibers such as polypropylene (PP) and polyester (PET). These materials are chosen for their strength, lightweight nature, and cost-effectiveness.

Polypropylene is one of the most frequently utilized materials in nonwoven bag design. Its benefits include high tensile strength, resistance to wear and tear, and the ability to be easily molded into various shapes and sizes. Furthermore, PP is also resistant to most chemicals, making it ideal for a wide range of uses. However, its non-biodegradable nature raises environmental concerns, necessitating proper disposal or recycling methods.

Polyester, another common material, offers excellent durability and resistance to stretching and shrinking. It is also less prone to wrinkles and abrasions, ensuring the bag remains aesthetically pleasing over time. Despite these advantages, polyester production involves significant energy consumption and the release of harmful emissions, which can be a drawback for environmentally conscious consumers.

In recent years, eco-friendly materials have gained traction in nonwoven bag design. These materials, such as recycled PET (rPET) and biodegradable polypropylene, aim to reduce environmental impact while maintaining the desired properties of strength and durability. Recycled PET, derived from used plastic bottles, exemplifies the circular economy by reusing waste and reducing the need for virgin plastic production. Biodegradable polypropylene, while still in development, promises to offer the functional benefits of traditional PP with enhanced biodegradability, addressing long-term environmental concerns.

The choice of material in nonwoven bag design significantly influences the bag’s usability and ecological footprint. Designers must balance the need for durability and performance with environmental considerations, ensuring that the final product meets both consumer expectations and sustainability goals. As innovation continues in the field of materials science, the options for creating effective and eco-friendly nonwoven bags are expected to expand, presenting new opportunities for designers and manufacturers alike.

Durability and Strength

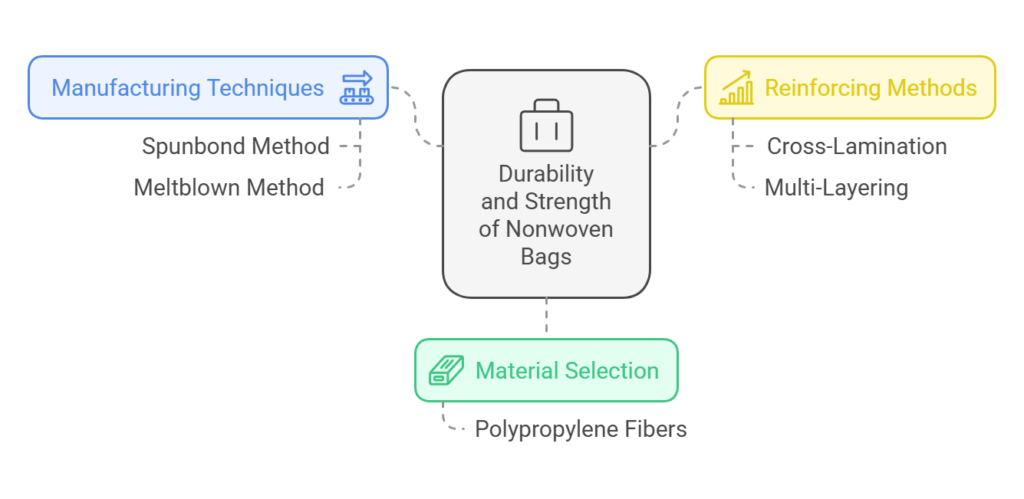

The durability and strength of nonwoven bags are pivotal elements in their design, ensuring that these bags are not only reusable but also capable of carrying a substantial load. The choice of materials and the manufacturing techniques employed play a significant role in enhancing these attributes. Typically, nonwoven bags are made from polypropylene fibers, which are bonded together through various processes such as spunbond, meltblown, or a combination of both. These methods contribute to the overall robustness of the fabric, making it resistant to wear and tear.

One of the primary techniques used to enhance the strength of nonwoven bags is the spunbond method. In this process, thermoplastic polymers are extruded to form continuous filaments, which are then laid into a web and bonded together through heat and pressure. This results in a fabric that is not only strong but also lightweight. Another technique, the meltblown method, involves extruding molten polymer through small nozzles surrounded by high-speed blowing gas. The resulting microfibers are then collected on a conveyor belt and bonded thermally or chemically, producing a fabric with excellent barrier properties.

To illustrate the effectiveness of these techniques, consider the case of grocery stores that have adopted nonwoven bags as an eco-friendly alternative to plastic bags. These bags are designed to withstand the rigors of carrying heavy items like canned goods and bottles without tearing. For instance, a study conducted by the Environmental Protection Agency (EPA) found that nonwoven polypropylene bags can carry loads up to 22 pounds, making them far more durable than traditional plastic bags.

Moreover, some manufacturers have integrated reinforcing techniques such as cross-lamination and multi-layering to further enhance the strength of nonwoven bags. These methods ensure that the bags remain intact even under significant stress, thereby extending their usability. As a result, nonwoven bags not only serve as a sustainable option but also offer superior durability and strength, making them a reliable choice for both consumers and businesses.

Environmental Impact

Nonwoven bags have garnered attention for their positive environmental impact, especially when compared to traditional materials like plastic and paper. One of the primary reasons nonwoven bags are considered more sustainable is their longevity and reusability. Unlike single-use plastic bags that often end up in landfills or oceans, nonwoven bags are designed for multiple uses, thereby reducing the frequency of disposal and the overall waste generated.

Recyclability is another significant advantage of nonwoven bags. These bags are often made from polypropylene, a type of plastic that can be recycled, albeit with some limitations. While the infrastructure for recycling polypropylene is not as widespread as it is for materials like PET (used in plastic bottles), strides are being made to improve this. Recycling nonwoven bags not only conserves resources but also minimizes the carbon footprint associated with producing new materials.

In terms of biodegradability, nonwoven bags offer a mixed bag of benefits and challenges. While polypropylene is not biodegradable, there are advancements in the development of biodegradable nonwoven materials. These innovations aim to provide the durability of traditional nonwoven bags while also ensuring that they break down more efficiently when discarded, thus reducing their long-term environmental impact.

Certifications play a crucial role in verifying the environmental friendliness of nonwoven bags. Labels such as the Global Recycled Standard (GRS) and the Oeko-Tex Standard 100 can indicate that the bags have been produced using sustainable practices and materials. These certifications help consumers make informed choices, knowing that the products they are using have been vetted for their environmental impact.

Comparatively, nonwoven bags offer a more environmentally responsible option than single-use plastic and even paper bags, which often require significant resources for production and may not be as durable. Through their recyclability, potential for biodegradability, and adherence to environmental certifications, nonwoven bags represent a step towards more sustainable consumption and waste management practices.

Design Aesthetics

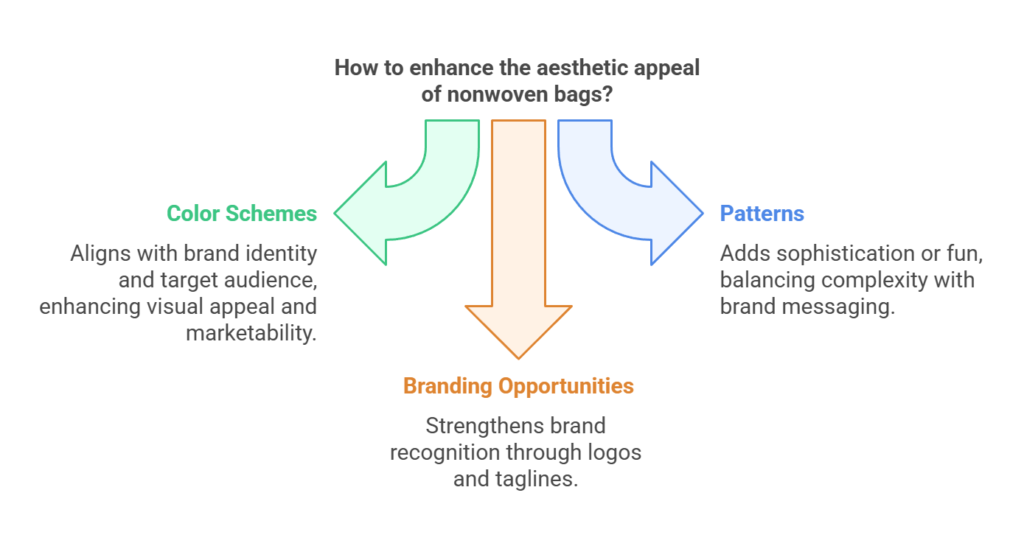

Design aesthetics play a crucial role in the nonwoven bag design process, influencing both the bag’s visual appeal and its marketability. Color schemes, patterns, and branding opportunities are integral components that can significantly enhance the overall attractiveness of these environmentally-friendly products. A well-thought-out design can capture consumer attention and drive purchasing decisions, making it a vital aspect of nonwoven bag creation.

When selecting a color scheme for a nonwoven bag, it is essential to consider the target audience and the brand’s identity. Colors should not only be aesthetically pleasing but also align with the brand’s message and values. For instance, eco-friendly brands often opt for earthy tones such as greens and browns to emphasize their commitment to sustainability. In contrast, a more vibrant color palette might be suitable for brands targeting younger, trend-conscious consumers.

Patterns also play a significant role in enhancing the visual appeal of nonwoven bags. Geometric shapes, floral designs, and abstract patterns can add an element of sophistication or fun, depending on the desired effect. However, it is important to strike a balance; overly complicated patterns may overshadow the brand message or make the bag look cluttered. Simplicity often reigns supreme in design, ensuring that the bag remains both functional and stylish.

Branding opportunities should not be overlooked in nonwoven bag design. Incorporating a company logo, tagline, or other brand elements can create a cohesive look that strengthens brand recognition. Positioning the logo prominently and ensuring it contrasts well with the chosen color scheme can make it stand out, thereby enhancing the bag’s marketability. Additionally, incorporating unique design elements that reflect the brand’s ethos can create a lasting impression on consumers.

To create visually appealing nonwoven bags that attract consumers, designers should follow a few key tips. Firstly, maintaining consistency in design elements such as colors, fonts, and logos helps establish a strong brand identity. Secondly, understanding consumer preferences and market trends can guide the selection of patterns and colors. Lastly, ensuring that the design is both functional and aesthetically pleasing will enhance the bag’s overall appeal, making it a desirable choice for consumers.

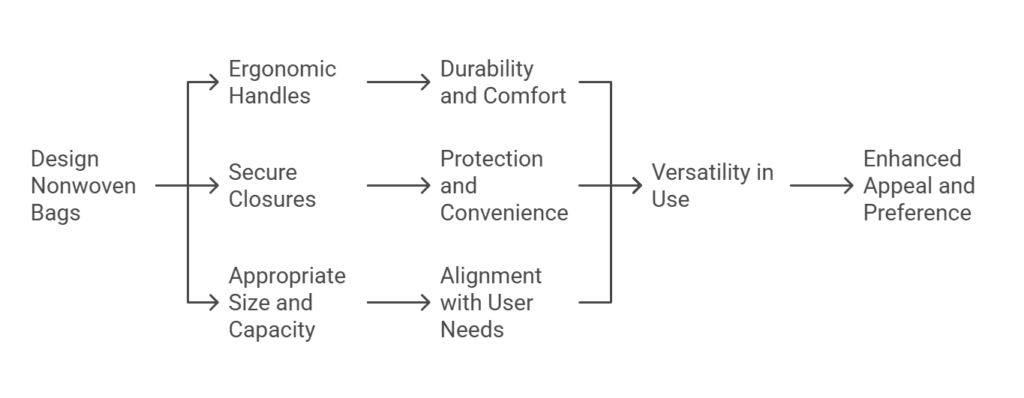

Functionality and Usability

When considering the design of nonwoven bags, functionality and usability are paramount. A pivotal aspect of their functionality lies in the handles. Handles must be ergonomically designed to ensure comfort and ease of carrying, especially when the bag is loaded with items. Sturdy, well-stitched handles provide durability and can enhance the bag’s lifespan, making it a reliable companion for various uses.

Closures are another critical feature influencing the usability of nonwoven bags. Whether using zippers, buttons, or Velcro, a secure closure mechanism is essential to protect the contents of the bag. A well-designed closure not only ensures that items stay safely inside but also adds to the overall user experience by offering convenience and peace of mind.

Size and capacity are also vital factors in the functionality of nonwoven bags. The dimensions of the bag should be appropriate for its intended use. For example, a smaller bag might be ideal for promotional giveaways, carrying just a few lightweight items. In contrast, a larger bag would be more suitable for grocery shopping or transporting bulkier items. The bag’s capacity must align with user needs, providing ample space without compromising on portability.

Additionally, the versatility of nonwoven bags makes them suitable for various contexts, from shopping trips to promotional events. For shopping, a well-sized and durable nonwoven bag can replace single-use plastic bags, supporting environmental sustainability. In the context of promotional events, these bags can serve as excellent marketing tools, combining functionality with brand visibility. The practical features of nonwoven bags, such as ample storage space and reliable closures, enhance their appeal, making them a preferred choice for consumers and businesses alike.

In essence, the functionality and usability of nonwoven bags are determined by a combination of factors including handles, closures, size, and capacity. These elements collectively contribute to the overall effectiveness and user satisfaction, making nonwoven bags a versatile and practical option for various applications.

Conclusion and Final Thoughts

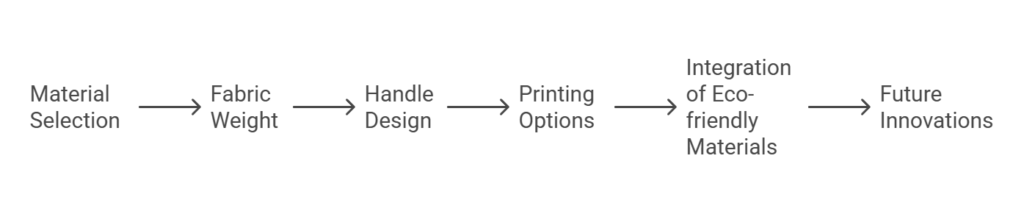

The design of nonwoven bags encompasses a variety of critical elements, each contributing to the overall functionality, aesthetic appeal, and sustainability of the final product. From material selection and weight to the handle design and printing options, every aspect plays a pivotal role in creating a nonwoven bag that meets the needs of both the consumer and the environment. The choice of material impacts durability and environmental footprint, while the weight of the fabric determines the bag’s strength and usability. Handle designs enhance user comfort and practicality, and advanced printing techniques offer customization that can cater to branding needs.

In light of these factors, it is clear that a thoughtful approach to each design element is essential for producing high-quality nonwoven bags. The integration of eco-friendly materials and innovative manufacturing processes not only supports sustainability efforts but also aligns with the growing consumer demand for environmentally responsible products. As businesses and consumers become more environmentally conscious, the emphasis on sustainable practices in nonwoven bag design will continue to rise.

Looking ahead, the future of nonwoven bag design is poised for exciting developments. Innovations in biodegradable materials and advanced manufacturing techniques are expected to drive further enhancements in both the functionality and eco-friendliness of these bags. Additionally, the increasing trend toward personalization and customization will likely influence new design trends, offering unique and tailored solutions for various market segments.

In conclusion, the key elements of nonwoven bag design—material choice, fabric weight, handle design, and printing options—collectively contribute to creating a product that is not only functional and aesthetically pleasing but also environmentally sustainable. As we move forward, continued innovation and a commitment to sustainability will be paramount in shaping the future of nonwoven bag design, ensuring these products meet the evolving needs of consumers and the planet.

FAQs

What are nonwoven bags made of?

Nonwoven bags are primarily made from polypropylene, a type of plastic polymer. The material is chosen for its durability, lightweight nature, and cost-effectiveness. During the manufacturing process, polypropylene fibers are bonded together using heat and pressure without weaving the fibers together, which distinguishes them from traditional woven fabrics.

How are nonwoven bags manufactured?

The manufacturing process of nonwoven bags involves several key steps. Firstly, polypropylene granules are melted and extruded into thin filaments. These filaments are then laid on a conveyor belt to form a web, which is subsequently bonded through thermal, chemical, or mechanical methods. Once the nonwoven fabric is produced, it is cut into specified shapes and sewn or heat-sealed to create finished bags. This method ensures the bags are sturdy, reusable, and capable of handling various loads.

Are nonwoven bags eco-friendly?

Nonwoven bags are considered more eco-friendly compared to single-use plastic bags. They are reusable, which significantly reduces the need for disposable plastic bags and helps in mitigating plastic pollution. Additionally, nonwoven bags can be recycled, although the process is more complex than recycling traditional plastics. Their longevity and reusability contribute to a reduction in overall waste, making them a more sustainable option for consumers and businesses alike.

Can nonwoven bags be customized?

Yes, nonwoven bags can be easily customized to meet specific requirements. They can be printed with logos, brand names, or any other designs using various printing techniques such as screen printing, heat transfer, and digital printing. This makes them an excellent choice for promotional purposes, as well as for retail and packaging needs where brand visibility is important.

What are the advantages of using nonwoven bags?

Nonwoven bags offer numerous advantages, including durability, cost-effectiveness, and environmental benefits. They are resistant to wear and tear, can carry heavy loads, and are available in various sizes and styles. Their reusability helps in reducing the consumption of single-use plastics, making them an eco-friendly alternative. Additionally, the customization options available make them versatile for different commercial and personal uses.

13 Responses

Vitazen Keto This is my first time pay a quick visit at here and i am really happy to read everthing at one place

Mat6tube This is my first visit here, and I’m so happy to read everything all in one spot

We’re thrilled to hear that! Thanks for stopping by our site, and we hope you’ll keep exploring our content. There’s much more to discover, and we look forward to your continued visits.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thank you for your comment and feedback. We truly appreciate that you took the time to read our article. We’d be more than happy to clarify any doubts you have. Please let us know which specific parts of the article you’re confused about, and we’ll do our best to provide more detailed and specific information.

Looking forward to hearing from you.

I love how you break things down into simple terms. It makes it so much easier to grasp the concept.

Thank you! Simplifying complex ideas is our goal to help readers like you better understand non – woven topics.

Its like you read my mind! You seem to grasp a lot approximately this, like you wrote the ebook in it or something. I believe that you simply can do with a few p.c. to power the message home a bit, but other than that, this is magnificent blog. A fantastic read. I will certainly be back.

Thank you so much for your kind words! I’m thrilled that the article resonated with you. Your feedback about adding a bit more punch is really valuable, and I’ll keep it in mind for future posts. Looking forward to having you back!

I love it when folks get together and share opinions. Great blog, keep it up!|

Thank you so much for your kind words and support! We’re thrilled you enjoy the shared opinions here. We’ll definitely keep up the good work!

Its such as you read my thoughts! You appear to grasp a lot approximately this, like you wrote the guide in it or something. I believe that you simply could do with a few to drive the message home a little bit, however instead of that, this is fantastic blog. A fantastic read. I’ll certainly be back.

Thank you so much for your kind words! Delighted to hear the blog resonated with you. Looking forward to having you back.