Introduction

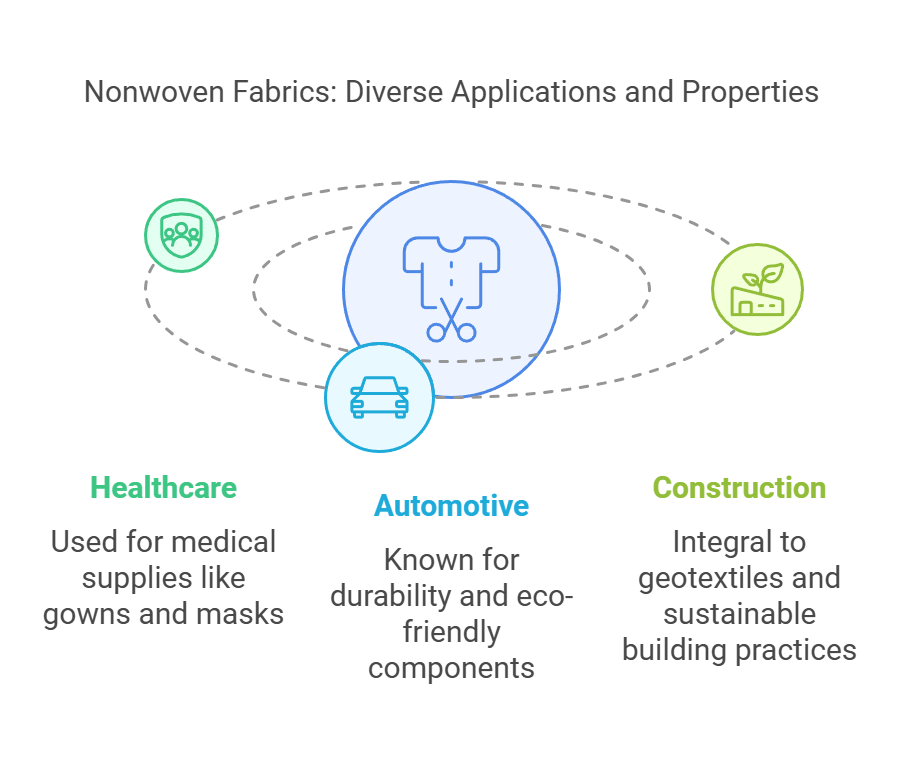

Nonwoven fabrics are engineered textile structures produced by bonding or interlocking fibers without the traditional weaving or knitting processes. They exhibit a diverse range of properties that make them uniquely suited for various applications. This innovative fabric type is formed through methods such as chemical, mechanical, heat, or solvent treatment, enabling a versatile solution tailored to specific requirements. The significance of nonwoven fabrics transcends their basic definition; they play a crucial role across multiple industries, including healthcare, automotive, and construction.

In the healthcare sector, nonwoven fabrics are widely utilized for medical supplies such as gowns, masks, and surgical drapes. Their inherent attributes, such as fluid resistance, breathability, and lightweight nature, ensure a high level of protection and comfort for both patients and providers. As public health demands increase, understanding the properties and applications of nonwoven materials becomes vital for anyone involved in medical supply chain processes.

Within the automotive industry, nonwoven fabrics have gained prominence due to their durability, sound absorption, and thermal insulation capabilities. From interior upholstery to composite structures, these fabrics contribute to enhancing vehicle performance and passenger comfort. As the automotive landscape evolves towards sustainability, nonwoven fabrics are emerging as eco-friendly alternatives for various components, driving the necessity for continued research into their unique characteristics and diversification.

In construction, nonwoven fabrics are integral to geotextiles, insulation materials, and roofing underlayment. Their strength, filtration properties, and ability to separate materials efficiently streamline numerous processes, resulting in increased durability and effectiveness. With an ever-growing emphasis on sustainable building practices and material reuse, nonwoven fabrics present innovative solutions that require a well-rounded understanding of their properties and varied applications.

Defining Nonwoven Fabrics: An Overview

Nonwoven fabrics are a distinctive category of textiles, characterized by their unique manufacturing process that differentiates them from traditional woven and knitted fabrics. Unlike woven textiles, which are produced by interlacing threads at right angles, or knitted fabrics that are created by interlocking yarns, nonwoven fabrics are engineered through a variety of methods that bond, entangle, or fuse fibers together. This fusion can be achieved through mechanical, thermal, or chemical means, leading to distinct attributes that set them apart.

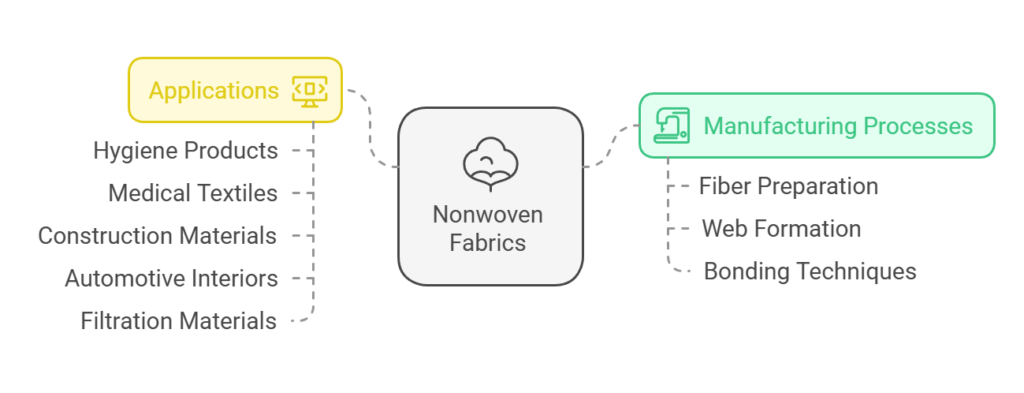

The manufacturing process of nonwoven fabrics typically involves several stages: fiber preparation, web formation, and bonding. Initially, raw fibers are processed and then laid out in a web, either through processes like carding or airlaying. Subsequently, the fibers are bonded through different techniques. For example, mechanical bonding uses needle punching to entangle fibers, while thermal bonding uses heat to fuse the fibers together. Additionally, chemical bonding can involve the application of adhesives to create strong links between the fibers. These methods result in a wide array of fabric types, each with varying properties suited for specific uses.

Key differences between nonwoven fabrics and their woven or knitted counterparts include their structure, strength, and application. Nonwoven fabrics often exhibit superior strength and durability due to their unique bonding methods, making them ideal for applications in hygiene products, medical textiles, construction, automotive interiors, and filtration materials. This versatility can be attributed to the absence of warp and weft yarns, allowing manufacturers to tailor the fabric’s properties, such as porosity, absorbency, and resilience, to meet specific needs effectively.

Overall, the innovative methods used in the production of nonwoven fabrics contribute to their unique characteristics, enabling diverse applications across various industries. As such, understanding the fundamental aspects of nonwoven fabrics is essential for selecting the right material for specific needs.

Key Characteristics of Nonwoven Fabrics

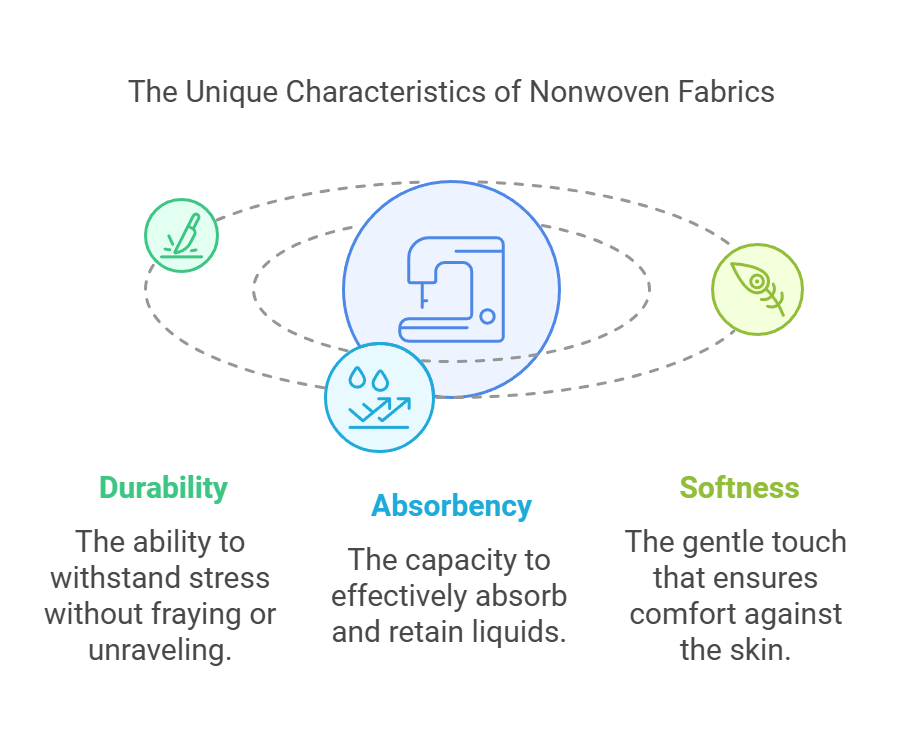

Nonwoven fabrics possess a unique set of characteristics that distinguish them from woven and knitted textiles. One of the fundamental properties is their inherent durability. Unlike traditional fabrics that may fray or unravel, nonwoven materials are created through processes such as bonding or thermal fusion, resulting in a strong fabric that can withstand various stresses. This durability makes nonwoven fabrics ideal for applications in industries ranging from healthcare to construction, where resilience is paramount.

Another vital characteristic of nonwoven fabrics is their absorbency. These materials can effectively absorb liquids, making them suitable for products such as absorbent pads, hygiene products, and medical applications. The absorbent nature arises from the fiber structure, which allows for efficient liquid retention and wicking, further expanding the range of uses. This quality is particularly beneficial in personal care items, where maintaining skin dryness or moisture management is essential.

Softness is also a significant trait that enhances the appeal of nonwoven fabrics. Unlike some woven materials that may be coarse or irritating against the skin, nonwoven fabrics offer a gentle touch. This softness is crucial for applications in the medical and personal care sectors, where comfort is a priority. Products such as surgical masks and diapers rely on this characteristic to ensure effective and comfortable use.

The combination of durability, absorbency, and softness not only makes nonwoven fabrics versatile but also allows them to adapt to various industrial and consumer needs. These unique characteristics contribute to their increasing popularity across multiple sectors, enabling innovative solutions tailored to specific requirements. As industries continue to evolve, the adaptability of nonwoven fabrics will undeniably play a significant role in meeting diverse challenges.

Diversification of Nonwoven Fabrics: Types and Uses

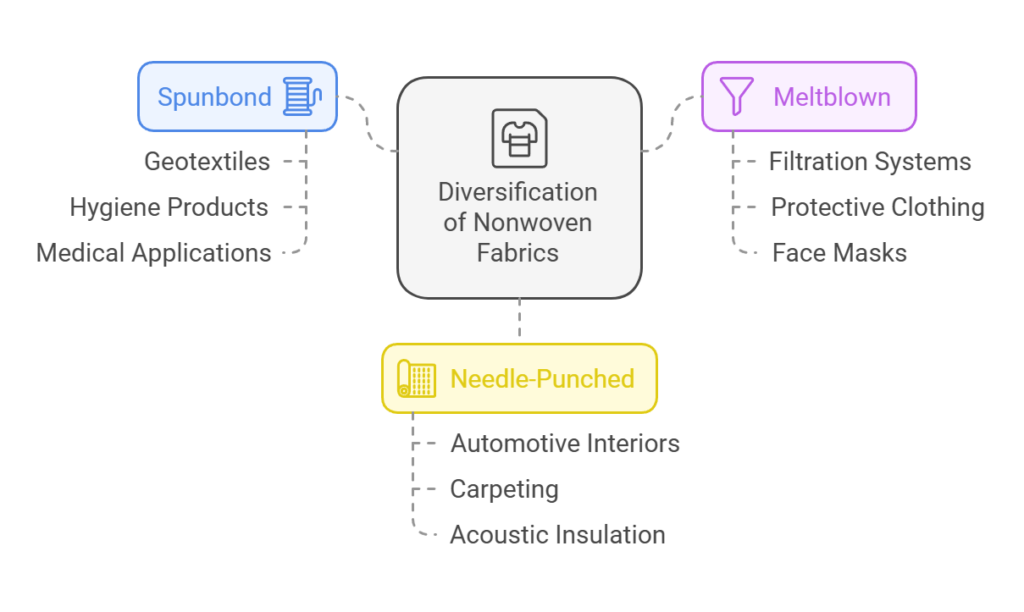

Nonwoven fabrics have gained significant traction in various industries due to their versatility, cost-effectiveness, and unique characteristics. The diversification of these materials results in several types, each tailored for specific applications. Among the most prominent types of nonwoven fabrics are spunbond, meltblown, and needle-punched. Each type serves distinctive purposes and presents unique advantages that make them suitable for an array of industry applications.

Spunbond nonwoven fabric is produced by extruding melted polymers into continuous filaments that are then laid down to form a web. This type of fabric is known for its high strength, durability, and resistance to tearing. Spunbond is often used in the production of geotextiles, hygiene products, and medical applications such as surgical gowns and masks. Its lightweight nature and excellent air permeability make it a preferred choice in areas requiring both comfort and performance.

Meltblown nonwoven fabrics, on the other hand, are created by blowing melted polymer fibers through high-velocity air streams, resulting in a finer web structure. This type offers exceptional filtration properties and is primarily employed in applications that require high absorbency and barrier functions, including air and liquid filtration systems, protective clothing, and face masks. The unique structure of meltblown fabric allows it to capture microscopic particles, making it invaluable in industrial and healthcare settings.

Needle-punched nonwoven fabrics are manufactured by mechanically entangling fibers using barbed needles. This process enhances the fabric’s thickness and density, leading to improved insulation and durability. Needle-punched fabrics find usage in a variety of applications, including automotive interiors, carpeting, and acoustic insulation. Their sound-absorbing qualities make them particularly advantageous in environments where noise reduction is essential.

In conclusion, the diversification of nonwoven fabrics underscores their adaptability and the numerous options available to meet specific industry needs. Understanding the types and corresponding applications of nonwoven materials enables manufacturers and consumers to select the most appropriate fabric for their projects.

Innovative Applications of Nonwoven Fabrics

Nonwoven fabrics have emerged as a versatile material across various industries, thanks to their unique properties. These fabrics, produced by bonding fibers together through mechanical, thermal, or chemical processes, offer distinct advantages that facilitate innovative applications. One of the most significant fields leveraging nonwoven textiles is personal protective equipment (PPE). With the rise of global health concerns, the demand for effective PPE has surged. Nonwoven materials are utilized in masks, gowns, and face shields, providing essential protection due to their excellent barrier properties while remaining breathable and comfortable for the wearer.

In addition to PPE, nonwoven fabrics have found a crucial role in filtration applications. The ability to create fine, even pore structures makes nonwoven materials ideal for air and liquid filtration systems. They are used in applications ranging from HVAC systems to water filtration, where their efficiency can significantly enhance performance. The lightweight and customizable nature of nonwoven fabrics allows for the development of innovative filtration products that meet specific requirements, such as high dirt-holding capacity and low pressure drop, making them a preferred choice for manufacturers in this sector.

Furthermore, the medical products sector has greatly benefited from nonwoven innovations. Absorbent dressings, surgical drapes, and hygiene products like diapers and adult incontinence pads are all prominent examples where nonwoven fabrics excel. Their ability to control fluid penetration and provide comfort makes them invaluable in medical applications. Additionally, as medical technology advances, nonwoven fabrics are being adapted for new usages such as drug delivery systems and implantable devices, illustrating their potential to evolve with the industry’s needs.

The unique characteristics of nonwoven fabrics, such as their adaptability and performance advantages, continue to inspire advancements across these fields, demonstrating their critical role in shaping innovative solutions to modern challenges.

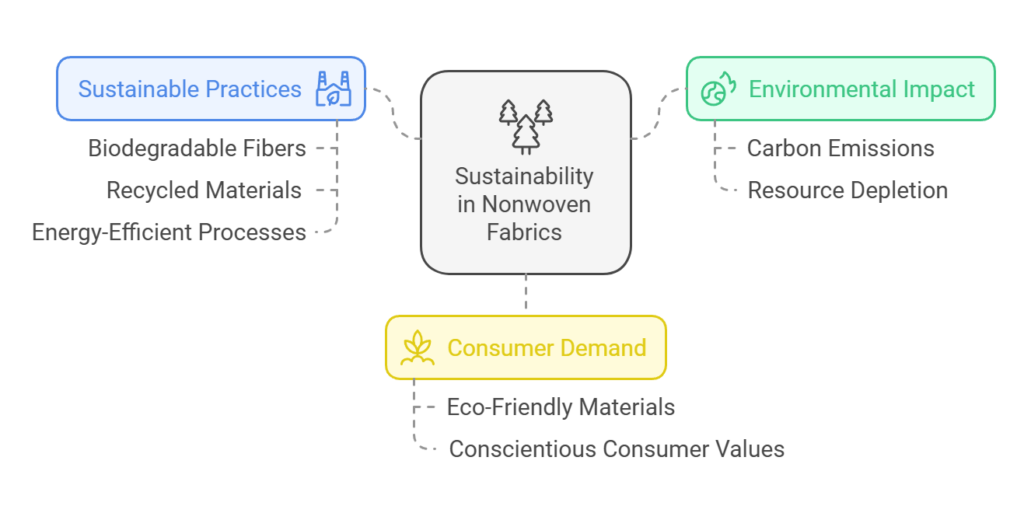

Environmental Impact and Sustainability in Nonwoven Fabrics

The production and disposal of nonwoven fabrics have garnered increasing attention due to their environmental implications. Traditionally, many nonwoven materials are derived from petroleum-based sources, contributing significantly to carbon emissions and reliance on nonrenewable resources. As the world grapples with climate change and environmental degradation, it becomes imperative to assess the sustainability of nonwoven products. This scrutiny has prompted the industry to adopt eco-friendlier practices and alternative materials.

One prominent trend within nonwoven fabric production is the shift towards biodegradable and compostable fibers. Natural fibers such as cotton, jute, and hemp have gained popularity, offering a renewable alternative to synthetic counterparts. Additionally, advancements in technology have led to the development of nonwoven fabrics made from recycled plastics, minimizing waste and promoting circular economy practices. Companies are increasingly integrating these sustainable materials into their product lines, responding to growing consumer demand for environmentally responsible options.

The industry is also witnessing a transformation in manufacturing processes that prioritize sustainability. Many nonwoven fabric producers are investing in energy-efficient technologies and adopting practices that reduce water and energy consumption. Innovative techniques, such as spunlace and needlepunching, are being utilized to enhance output while minimizing the environmental footprint. Furthermore, manufacturers are exploring eco-friendly dyes and chemicals, reducing the ecological hazards associated with traditional textile processing.

In conclusion, as the nonwoven fabric industry continues to evolve, its commitment to sustainability is becoming more pronounced. The shift towards sustainable materials, coupled with innovative manufacturing processes, not only lessens the environmental impact but also aligns with the values of conscientious consumers. By adapting to these eco-friendly innovations, companies in the nonwoven sector are paving the way for a more sustainable future in textiles.

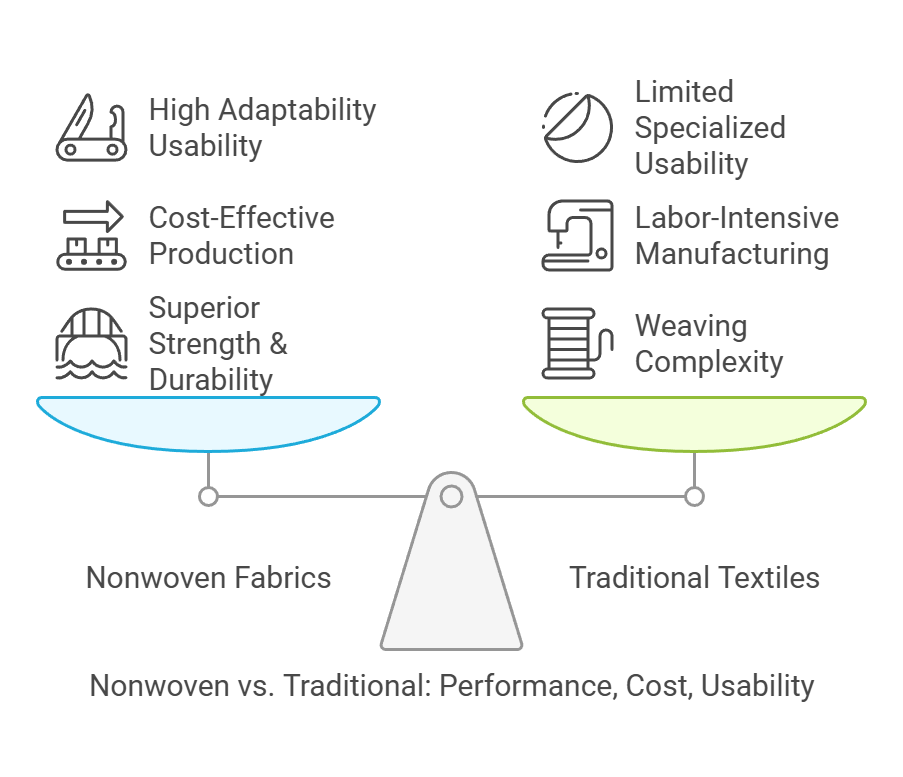

Comparative Analysis: Nonwoven vs. Traditional Textiles

Nonwoven fabrics are increasingly recognized for their distinct advantages compared to traditional textiles. One significant area of comparison lies in performance. Nonwoven fabrics, which are engineered through processes such as bonding, felting, or layering, generally exhibit superior strength and durability. They are often designed to cater to specific applications, which can result in enhanced performance characteristics like water resistance, breathability, and filtration capabilities. In contrast, traditional textiles, made from woven or knitted structures, can be less versatile in their functional applications, often requiring additional treatments to match the specialized uses nonwoven fabrics can offer.

Cost-effectiveness is another critical factor where nonwoven fabrics present a compelling argument. The production of nonwoven fabrics tends to require less time and labor compared to traditional textile manufacturing, which involves intricate weaving or knitting processes. This streamlined production can translate to lower costs, making nonwoven options attractive for industries looking to optimize budgets. Additionally, nonwoven materials often generate less waste during manufacturing, further enhancing their cost-effectiveness and environmental appeal. In sectors where budget constraints are paramount, this economic advantage can influence the choice of fabric type significantly.

Usability is also a key differentiator between nonwoven and traditional textiles. Nonwoven fabrics exhibit a remarkable degree of adaptability, making them suitable for various applications, including hygiene products, medical supplies, and filtration systems. The skip of weaving provides smoother surfaces and a more uniform structure, which can be essential for certain end-use applications. Traditional textiles, while well-established in clothing and soft furnishings, may not serve well in specialized sectors where specific material properties are required. This nuanced understanding of fabric types and their respective usability highlights why certain industries lean towards the adoption of nonwoven fabrics over conventional textiles, ultimately allowing for innovation and efficiency tailored to modern demands.

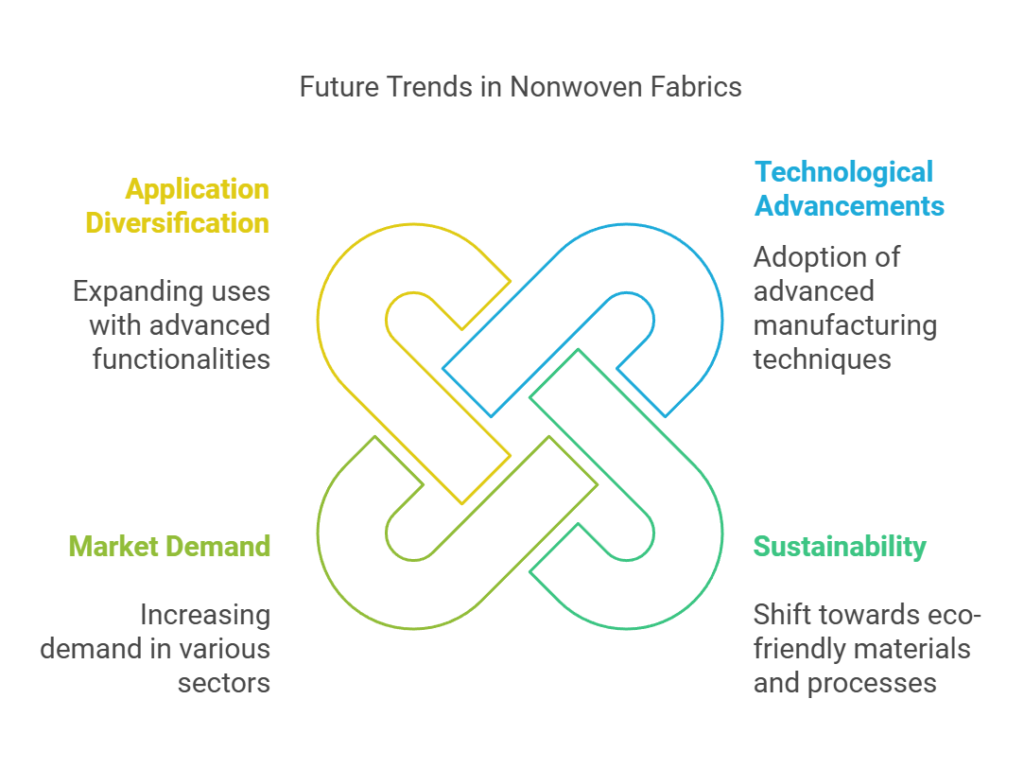

Future Trends in Nonwoven Fabric Diversification

The nonwoven fabric industry is poised for significant growth and transformation in the coming years, driven by various technological advancements and increasing market demand. One of the most notable trends is the adoption of advanced manufacturing techniques that enhance production efficiency and product versatility. Innovations such as spunbonding, meltblowing, and hydroentangling are set to improve the quality and performance of nonwoven fabrics, making them suitable for an even wider array of applications.

The expanding market for sustainable and eco-friendly materials is another key facet influencing the future of nonwoven fabric diversification. As consumers and industries alike prioritize environmental stewardship, manufacturers are exploring biodegradable materials and recycling processes to reduce the environmental footprint of nonwovens. This pivot towards sustainability not only addresses regulatory pressures but also enhances brand loyalty among environmentally conscious consumers.

Market growth predictions indicate a robust increase in demand for nonwoven fabrics across sectors such as hygiene, medical, automotive, and construction. The hygiene sector, in particular, is expected to witness remarkable expansion due to rising birth rates and heightened awareness regarding personal care and health. Similarly, the medical field’s need for sterilizable and disposable products is fostering a surge in nonwoven applications, particularly in wound care and surgical masks.

Furthermore, the ongoing diversification of nonwoven applications is projected to shape future innovations. The industry is expected to diversify beyond traditional uses, integrating advanced functionalities such as antimicrobial properties, water repellency, and built-in sensors. These additions will open new avenues in fields ranging from smart textiles to filtration solutions.

In conclusion, the future of nonwoven fabric diversion is bright, with emerging trends likely to reshape the landscape significantly. Continued investments in technology, sustainability practices, and diversification of applications will be essential for tapping into new market opportunities and addressing the needs of an evolving consumer landscape.

FAQs About Nonwoven Fabrics

Nonwoven fabrics have gained popularity across various industries due to their diverse applications and unique properties. To enhance understanding, we will address some frequently asked questions regarding these innovative materials.

What are nonwoven fabrics? Nonwoven fabrics are engineered materials made from fibers that are bonded through mechanical, thermal, or chemical processes rather than being woven or knitted. This manufacturing method yields a fabric that is generally less expensive and has varying thicknesses and textures suitable for different applications. Nonwoven fabrics can be produced using a variety of fibers, including polyester, polypropylene, and natural fibers like cotton, making them versatile materials.

What are the primary applications of nonwoven fabrics? The applications of nonwoven fabrics are vast and diverse. They can be found in industries such as healthcare for masks, gowns, and surgical drapes; in automotive manufacturing for insulation and upholstery; and in construction for geotextiles. Their ability to be engineered for specific properties makes them suitable even for household items such as cleaning wipes and hygiene products, highlighting their important role in our daily lives.

Are nonwoven fabrics environmentally friendly? The environmental impact of nonwoven fabrics largely depends on the materials used and the manufacturing processes involved. Many nonwoven products are designed for single-use applications, but advancements in recycling techniques and the use of biodegradable fibers are increasingly making this fabric type more sustainable. Additionally, because nonwoven fabrics can be less resource-intensive to produce compared to woven materials, they can offer more eco-friendly options within specific contexts.

What sets nonwoven fabrics apart from other fabric types? Unlike traditional woven fabrics, nonwoven textiles are characterized by their unique production methods that allow for specific functionalities and properties to be engineered into the fabric. This includes attributes such as enhanced durability, resistance to moisture, and breathability, which are tailored according to the intended application, making nonwoven fabrics versatile components across a multitude of sectors.

Understanding these characteristics helps clarify the emerging role of nonwoven fabrics in modern applications, highlighting their advantages, versatility, and potential impact on various industries.

14 Responses

“Well explained, made the topic much easier to understand!”

Thanks! Glad it was helpful.

I loved as much as youll receive carried out right here The sketch is tasteful your authored material stylish nonetheless you command get bought an nervousness over that you wish be delivering the following unwell unquestionably come more formerly again since exactly the same nearly a lot often inside case you shield this hike

Thanks for your comment! Glad you liked it. We’ll keep striving to provide great content. 😊

Hello Neat post Theres an issue together with your site in internet explorer would check this IE still is the marketplace chief and a large element of other folks will leave out your magnificent writing due to this problem

Thank you for your comment. We will look into the issue with Internet Explorer.

“Great content, learned a lot from this post!”

Thank you! Glad you found it useful.

Baddiehub You’re so awesome! I don’t believe I have read a single thing like that before. So great to find someone with some original thoughts on this topic. Really.. thank you for starting this up. This website is something that is needed on the internet, someone with a little originality!

Thanks! Glad you liked it. 😊

Blue Techker This is really interesting, You’re a very skilled blogger. I’ve joined your feed and look forward to seeking more of your magnificent post. Also, I’ve shared your site in my social networks!

Thank you for your kind words! Glad you enjoyed it. 😊

Your blog is a treasure trove of valuable insights and thought-provoking commentary. Your dedication to your craft is evident in every word you write. Keep up the fantastic work!

Thank you so much! Your kind words mean the world to me. I’ll definitely keep striving to bring more great content.