Introduction

Nonwoven fabric is an innovative material widely utilized across numerous industries due to its unique properties and versatility. Unlike traditional woven or knitted textiles, nonwoven fabrics are constructed through the bonding of fibers, creating a strong, durable product that serves a multitude of purposes. This fabric can be produced from various types of fibers, including natural and synthetic materials, which further enhance its applicability in many sectors.

The significance of nonwoven fabric is particularly evident in the medical, automotive, construction, and hygiene industries. In the healthcare sector, for instance, nonwoven materials are essential for the manufacture of surgical masks, gowns, and for covering surgical instruments, ensuring hygiene and safety. Furthermore, in the automotive industry, nonwoven fabric is commonly used for insulation, sound absorption, and filtration. The construction industry employs it for geotextiles, providing soil stabilization and drainage solutions, while the hygiene sector relies on nonwoven materials for products like diapers and adult incontinence pads.

Given the diverse applications of nonwoven fabric, understanding the factors that influence its pricing becomes crucial for manufacturers and consumers alike. The cost of nonwoven fabric can vary significantly based on several components, including the type of fibers used, production methods, and the complexity of the intended application. In light of this importance, the subsequent sections will delve deeper into the various elements that contribute to the pricing of nonwoven fabric, leading to an enlightening discussion about its value in the market.

Understanding Nonwoven Fabric

Nonwoven fabric is a unique textile material made from fibers that are bonded together through various processes, rather than being woven or knitted. This results in a fabric that possesses distinctive characteristics and offers a range of benefits compared to traditional textiles. The composition of nonwoven fabric typically involves synthetic fibers, such as polypropylene or polyester, but natural fibers like cotton or jute can also be employed, depending on the intended use. The diversity in fiber selection contributes to the versatility of nonwoven fabrics in applications ranging from hygiene products to medical supplies.

The manufacturing processes used to create nonwoven fabrics generally fall into several categories, including spunbond, meltblown, and needlepunched techniques. Spunbond involves extruding melted polymer polymers into fine filaments, which are then laid down and bonded to form a continuous sheet. Meltblown, on the other hand, utilizes high-velocity hot air to produce fine fibers from melted thermoplastic materials, creating a material with excellent filtration properties. Needlepunched fabrics are formed by mechanically entangling fibers with barbed needles, producing a durable and cohesive structure. Each method results in various nonwoven fabric types, each embodying specific qualities suited to different applications.

One of the main distinctions between nonwoven and traditional woven or knitted fabrics is the manner in which they are constructed. Woven fabrics consist of interlaced yarns, while knitted fabrics are produced by interlooping threads. This structural difference results in varying degrees of strength, stretch, and durability. Nonwoven fabrics often offer advantages such as lower production costs, customized textures, lightweight compositions, and enhanced filtration capabilities. As a result, they are increasingly utilized in diverse sectors including healthcare, automotive, and fashion, reflecting their significant versatility in today’s textile market.

Factors Affecting Nonwoven Fabric Price

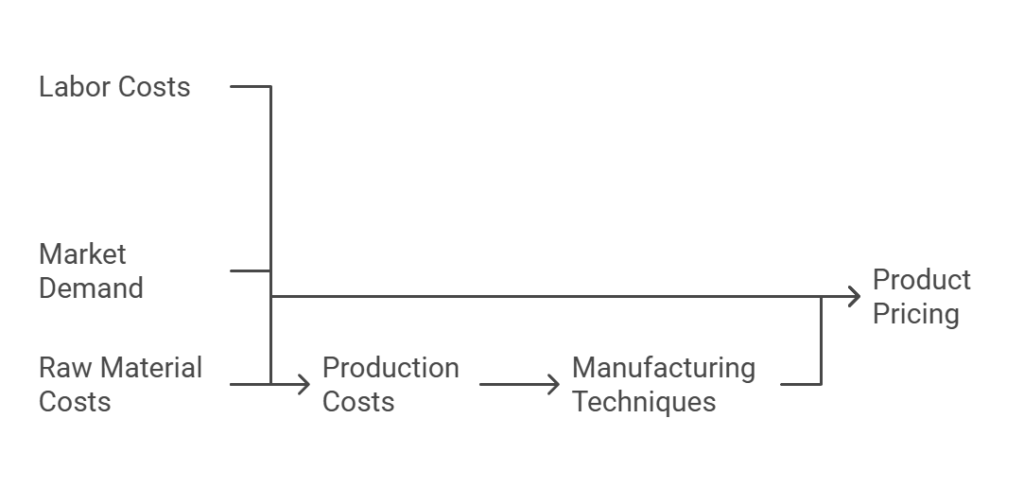

The price of nonwoven fabric is influenced by a multitude of factors that collectively shape its market value. A primary consideration is the cost of raw materials. Nonwoven fabrics can be produced from various materials, including polyester, polypropylene, and biodegradable fibers. Fluctuations in the prices of these raw materials, driven by market demand and supply chain dynamics, directly impact the overall cost of the final product. For instance, any increase in the price of petroleum-based products can lead to higher production costs for polypropylene-based nonwovens.

Another critical factor is the manufacturing techniques employed in the production of nonwoven fabrics. Different methods, such as spunbond, meltblown, and needlepunch, each come with varying operational costs. Advanced technologies and processes can enhance the properties of nonwoven fabrics, such as strength, absorbency, and barrier properties. However, employing sophisticated manufacturing techniques incurs higher production costs, which may subsequently lead to increased pricing for the end consumer. Therefore, manufacturers often weigh the trade-offs between production efficiency and product quality.

Labor costs also play a significant role in determining the price of nonwoven fabric. Regions with higher labor costs may see increased prices for nonwoven fabrics produced in those areas. Additionally, labor regulations and the complexity of the manufacturing process contribute to overall pricing strategies. Machines and labor must work in harmony to optimize production, and any disruptions can lead to inefficiencies that escalate costs.

Lastly, market demand is a driving force behind nonwoven fabric pricing. As industries such as healthcare, automotive, and agriculture increasingly adopt nonwoven textiles for their diverse applications, demand surges may lead to higher prices. Conversely, during periods of oversupply, prices may stabilize or decrease. Consequently, understanding these factors is crucial for stakeholders aiming to navigate the nonwoven fabric market effectively.

Market Trends and Pricing Dynamics

The nonwoven fabric market has experienced significant fluctuations in pricing due to various influencing factors. Current market trends indicate that both supply chain challenges and geopolitical conditions play a crucial role in determining the price of nonwoven fabrics. Initially, the disruptions caused by the global pandemic led to material shortages and increased production costs, making it difficult for manufacturers to maintain competitive pricing.

Furthermore, geopolitical factors, such as trade restrictions and tariffs, have exacerbated these challenges. For instance, tensions between major economies can lead to unpredictable supply disruptions, further driving up costs. The increasing demand for nonwoven fabrics in industries such as healthcare, construction, and automotive has created additional pressure on suppliers to source raw materials at competitive prices. This heightened demand often leads to supply shortages, which can escalate pricing dynamics considerably.

Emerging technologies also play a vital role in shaping the future of nonwoven fabric production. Innovations in manufacturing processes may lead to more cost-effective alternatives, thereby influencing market pricing. Companies investing in automation and advanced materials science are expected to reduce production costs over time, potentially resulting in lower prices for consumers. Additionally, the rise of sustainable practices and eco-friendly materials is reshaping the industry, aligning with consumer preferences and regulatory demands. This shift could also impact pricing, as the costs associated with sourcing sustainable raw materials and processes may fluctuate.

Ultimately, understanding these market trends and pricing dynamics is essential for stakeholders in the nonwoven fabric industry. By adapting to these changes, businesses can better position themselves amidst ongoing fluctuations and remain competitive in a rapidly evolving market landscape.

Comparative Pricing: Nonwoven vs. Woven Fabrics

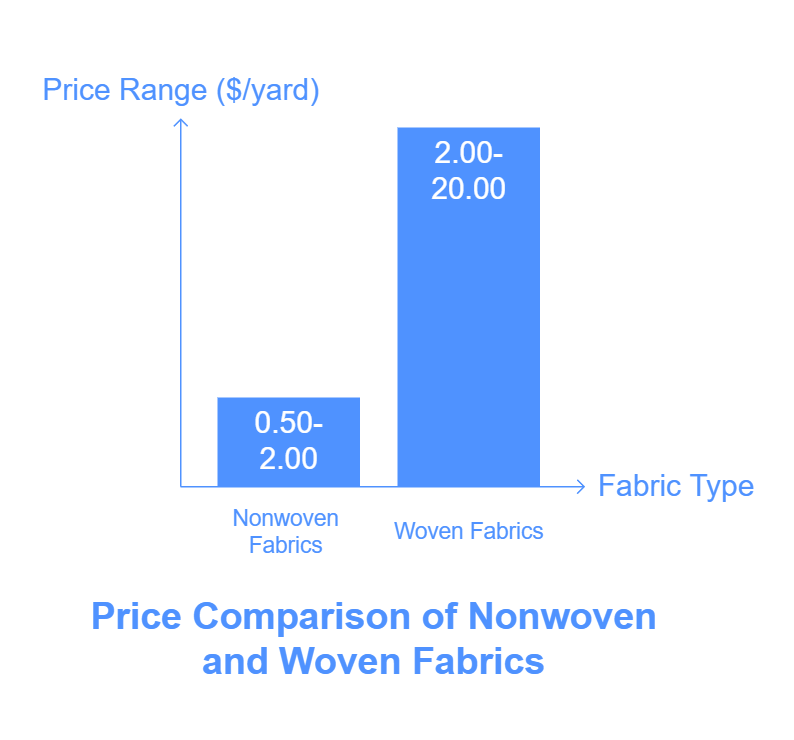

The pricing of textiles is a critical factor when determining the appropriate material for a given application. Nonwoven fabrics and woven fabrics exhibit notable differences in cost structures, production methods, and end-use value propositions. Generally, nonwoven fabrics tend to be less expensive to produce than their woven counterparts. This is primarily due to the different manufacturing processes involved. Nonwoven fabrics are created through a bonding process that requires less labor and fewer complex machinery setups compared to weaving operations, which necessitate the use of looms and intricate techniques.

The price range for nonwoven fabrics typically falls between $0.50 to $2.00 per yard, depending significantly on the fiber content, weight, and intended use. These fabrics, such as those used in disposable medical and hygiene products, often exhibit economies of scale. In contrast, woven fabrics can range vastly in price, from $2.00 to upwards of $20.00 per yard, influenced by the type of fiber, the complexity of the weave, and added finishes.

From a cost-effectiveness perspective, nonwoven fabrics can be advantageous in specific applications, particularly where bulk usage is anticipated. For example, in the production of disposable products like surgical masks or adult diapers, the lower material cost of nonwovens becomes a significant factor, making them the preferred choice. However, woven fabrics may offer enhanced durability and aesthetic appeal in applications like upholstery or fashion, ultimately justifying their higher price point. Additionally, woven textiles may provide better structural integrity and performance in demanding environments. Thus, the decision between nonwoven and woven options should consider not only the upfront costs but also the overall value and performance requirements of the end product.

Buying Guide: How to Purchase Nonwoven Fabric Cost-Effectively

When venturing into the purchase of nonwoven fabric, it is crucial for both consumers and businesses to adopt a strategic approach to ensure cost-effectiveness. The market for nonwoven fabrics is vast and includes various applications, from medical textiles to home decor. One of the most effective strategies is to thoroughly research suppliers and compare prices. This not only gives insights into the typical price range for your required fabric but also helps identify reputable manufacturers and distributors.

Another important consideration is sourcing. Engaging directly with manufacturers can lead to better pricing compared to purchasing through middlemen. Many suppliers offer discounts for large orders, so if you are buying in bulk, it is advisable to inquire about wholesale rates. Bulk purchasing often results in reduced per-unit costs, making it an advantageous option for businesses looking to streamline their expenses. Consequently, understanding your needs and calculating exact quantities ahead of time can save significant amounts.

Negotiating prices should not be overlooked. As a buyer, being open to discussions regarding price adjustments, especially for bulk purchases, can yield favorable results. Suppliers may provide discounts or incentives when committing to larger orders or long-term contracts. To enhance your negotiation position, consider presenting competitors’ pricing as a benchmark. This approach demonstrates awareness of the market and encourages suppliers to offer more competitive rates.

Lastly, staying updated on market trends can provide additional advantages. Prices for nonwoven fabrics can fluctuate based on raw material costs and demand. Engaging in industry networks and forums can be beneficial in gaining insights into upcoming changes, allowing for informed purchasing decisions. In conclusion, the integration of research, strategic sourcing, effective negotiation, and market awareness will result in purchasing nonwoven fabric at competitive prices.

Case Studies: Pricing in Different Applications

The pricing of nonwoven fabric varies significantly across diverse industries due to the unique specifications and regulations of each sector. The healthcare industry, for instance, places a premium on nonwoven materials primarily used in surgical gowns, masks, and various medical disposables. The stringent hygiene standards and the need for sterility necessitate advanced manufacturing processes which result in higher costs. Nonwoven fabrics for healthcare applications often undergo rigorous testing and certification, influencing their market price. A case study conducted in a leading medical textile manufacturer found that the price of specialized surgical nonwoven fabric could range from $5 to $25 per square meter, depending on the material properties and certifications required.

In the automotive industry, the application of nonwoven fabric serves various purposes, including soundproofing, insulation, and interior lining. The automotive sector tends to favor cost-effective solutions that maintain quality standards. A case highlighted by a prominent automotive supplier illustrated that the price for nonwoven fabric varied based on thickness, density, and performance characteristics. On average, the price for automotive-grade nonwoven fabric was quoted between $1 to $15 per square meter, reflecting the balance between quality demands and cost efficiency.

The construction industry also utilizes nonwoven fabrics in applications like geotextiles and insulation barriers. These fabrics play a crucial role in enhancing structural stability and longevity. A recent study showcased a geotextile company’s pricing strategy, revealing that nonwoven fabrics used in construction projects ranged from $0.50 to $10 per square meter. Factors impacting the price included durability, UV resistance, and the specific environmental conditions the products had to withstand.

These case studies illustrate that the cost of nonwoven fabric is intricately linked to its application. Industries adapt their pricing strategies based on their requirements, ultimately influencing market dynamics and consumer choices.

FAQs About Nonwoven Fabric Pricing

Understanding the pricing of nonwoven fabric is essential for both consumers and industry professionals. Many factors affect the cost of nonwoven fabrics, leading to various misconceptions. Below, we address some frequently asked questions to shed light on this critical topic.

What factors influence the price of nonwoven fabrics? The pricing of nonwoven fabric is affected by several variables such as the type of fibers used, manufacturing processes, and material quality. Additionally, the scale of production plays a significant role; larger orders often result in lower prices due to economies of scale. Furthermore, market demand and availability can impact pricing significantly, particularly if specific types of nonwoven fabrics are in high demand.

Are specialized nonwoven fabrics more expensive than standard types? Generally, yes. Specialized nonwoven fabrics, which are engineered for specific applications such as medical or filtration uses, usually come at a higher cost. This pricing reflects the additional research, development, and technology required to produce these advanced materials. Consumers should always evaluate their needs versus the costs when considering specialized options.

How can consumers find competitive pricing without compromising quality? To obtain competitive prices for nonwoven fabrics, it is advisable to compare quotes from multiple suppliers. Additionally, attending trade shows and industry events can provide insights into current pricing trends and innovations. Consumers should also consider the overall value provided by the supplier, including customer support and product consistency, rather than focusing solely on the lowest price.

By addressing these common queries, consumers and industry professionals can gain a clearer understanding of nonwoven fabric pricing, enabling them to make informed purchasing decisions for their specific needs.

Conclusion

In conclusion, understanding the pricing of nonwoven fabric is crucial for both consumers and businesses alike. As we have explored throughout this article, various factors influence the price of nonwoven fabrics, including raw material costs, production methods, and market demand. These pricing determinants can vary significantly based on geographical locations and prevailing industry trends. For instance, while synthetic fibers might offer cost efficiency, natural fibers’ growing popularity reflects changing consumer preferences that can shift market prices.

Furthermore, the market for nonwoven fabrics is characterized by constant evolution, driven by advancements in technology and growing sustainability concerns. As industry players innovate and improve production efficiency, it may lead to fluctuations in pricing structures. Thus, staying informed on these dynamics can empower buyers to make more educated purchasing decisions, ensuring they get the best value for their investment in nonwoven materials.

Moreover, understanding the competitive landscape is also vital. Numerous manufacturers exist in the nonwoven fabric sector, each employing distinct strategies that affect their pricing models and product offerings. Consequently, buyers should consider not just the price but also the quality and suitability of the fabric for their specific needs. In an ever-changing market, awareness of these dimensions will equip readers with a broader toolkit for navigating the purchasing landscape of nonwoven fabrics.

Ultimately, the significance of recognizing price determinants and market trends cannot be overstated. By internalizing these insights, stakeholders can achieve more favorable outcomes in their sourcing and procurement processes for nonwoven fabrics, benefiting from informed decision-making that aligns with their objectives.

8 Responses

you are in reality a just right webmaster The site loading velocity is incredible It seems that you are doing any unique trick In addition The contents are masterwork you have performed a wonderful task on this topic

Thank you for your kind words! I will keep working hard.

Technoob For the reason that the admin of this site is working, no uncertainty very quickly it will be renowned, due to its quality contents.

Thanks for your positive comment! We will keep providing quality contents.

Smartcric Good post! We will be linking to this particularly great post on our site. Keep up the great writing

Thanks! Glad you liked it. 😊

What i do not understood is in truth how you are not actually a lot more smartlyliked than you may be now You are very intelligent You realize therefore significantly in the case of this topic produced me individually imagine it from numerous numerous angles Its like men and women dont seem to be fascinated until it is one thing to do with Woman gaga Your own stuffs nice All the time care for it up

Thank you so much for your kind words and thoughtful comment! I’m really glad that you find the content intelligent and that it made you view the topic from different angles. Your support means a lot, and we’ll definitely keep up the good work. If you have any other thoughts or topics you’d like to see covered, feel free to let us know.