Introduction

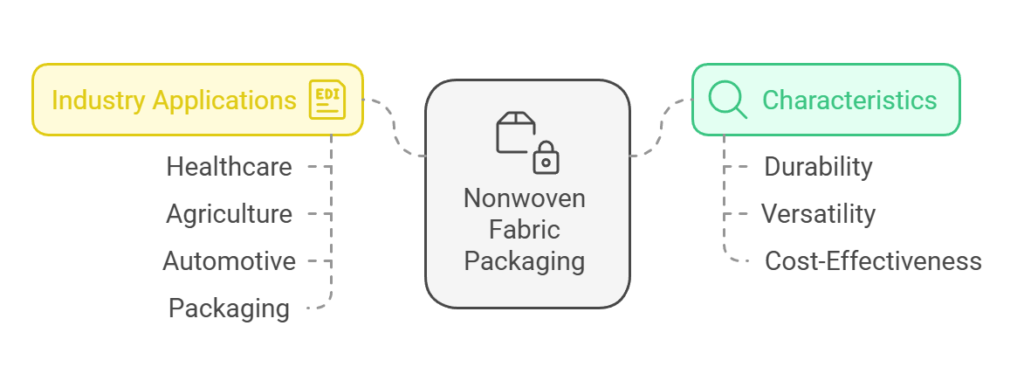

Nonwoven fabric packaging has emerged as a prominent trend within the packaging industry, owing to its diverse applications and numerous advantages. But what exactly are nonwoven fabrics? Unlike traditional textiles that are woven or knitted, nonwoven fabrics are engineered materials made from long fibers, bonded together by chemical, mechanical, heat, or solvent treatment. This unique fabrication process imparts specific characteristics to nonwoven fabrics, making them suitable for a myriad of uses.

Nonwoven fabrics are integral to various industries, including healthcare, agriculture, automotive, and, notably, packaging. In the packaging sector, their significance is particularly pronounced due to their durability, versatility, and cost-effectiveness. With the increasing demand for sustainable and efficient packaging solutions, nonwoven fabric packaging has found widespread acceptance as an eco-friendly alternative to traditional materials.

Understanding the benefits and uses of nonwoven fabric packaging is crucial for businesses and consumers alike. As markets progressively lean towards environmentally responsible and practical packaging options, nonwoven fabrics offer a compelling mix of efficiency, functionality, and sustainability. The subsequent sections will delve deeper into the specific advantages that nonwoven fabric packaging brings to the table, facilitating a well-rounded perspective for anyone considering this innovative solution.

What Are the Benefits of Nonwoven Fabric Packaging?

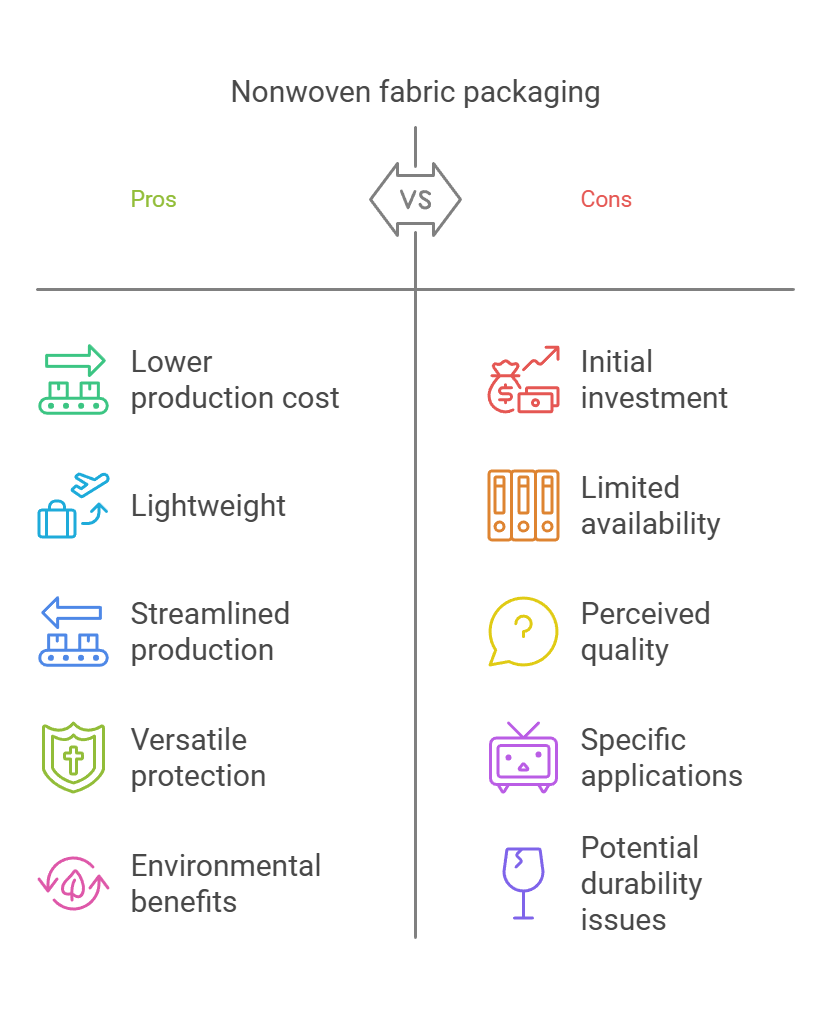

Nonwoven fabric packaging offers a myriad of benefits that elevate it above traditional packaging materials. One of its primary advantages is durability; nonwoven fabrics are known for their strength and resistance to wear and tear, ensuring that packaged items are well-protected during transportation and storage. This longevity also translates to cost-effectiveness. Businesses can save on packaging costs because the robust material reduces the need for frequent replacements.

Another significant benefit is eco-friendliness. Nonwoven fabrics are often made from recycled materials and are recyclable themselves, reducing the environmental footprint of packaging solutions. This aligns with the growing consumer demand for sustainable practices and can enhance a company’s reputation for environmental responsibility.

Customizability is another key advantage. Nonwoven fabrics can be easily tailored to different shapes, sizes, and designs, providing companies with the flexibility to create unique and appealing packaging that stands out in the marketplace. Additionally, this adaptability extends to branding opportunities, as nonwoven materials can be printed on easily, allowing for logos and brand messages to be prominently displayed.

Finally, the ease of production is a critical factor. Nonwoven fabrics can be manufactured quickly and efficiently, ensuring steady supply to meet business demands. This rapid production capability makes it possible for companies to respond swiftly to market changes and customer needs.

Overall, the combination of durability, cost-effectiveness, eco-friendliness, customizability, and ease of production establishes nonwoven fabric packaging as a superior choice. These attributes make it not only a practical solution but also a strategic asset for businesses aiming to optimize their packaging operations and meet contemporary consumer expectations.

Understanding Nonwoven Fabrics

Nonwoven fabrics are a type of material that are not woven or knitted from individual threads, but rather are manufactured by bonding together long fibers through chemical, thermal, or mechanical processes. This unique production method distinguishes nonwoven fabrics from traditional woven fabrics, which are created by interlacing threads in a regular pattern.

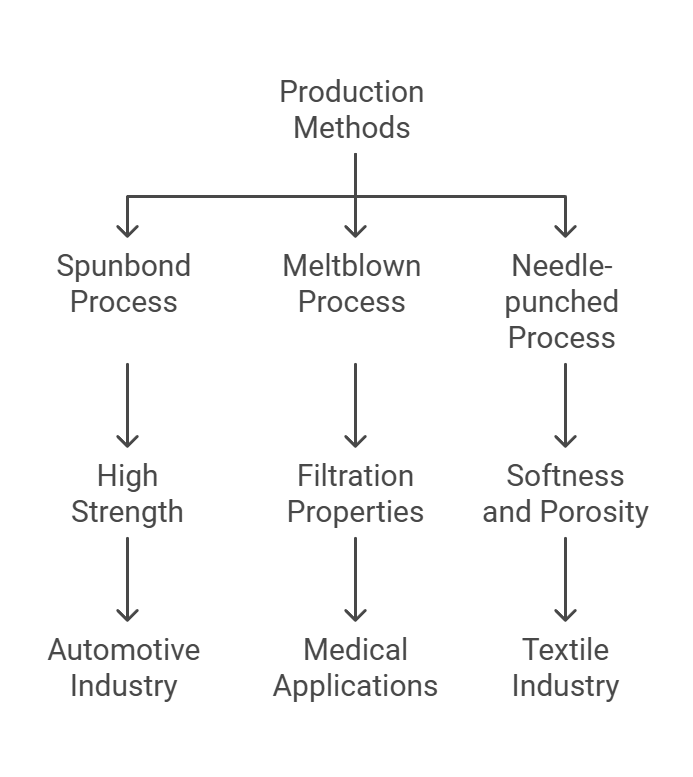

One of the primary methods of producing nonwoven fabrics is the spunbond process. In this technique, thermoplastic polymers are extruded, stretched, and laid into a continuous web, which is then bonded together through heat and pressure. Spunbond nonwoven fabrics are known for their high tensile strength and durability, making them suitable for uses that require robust and resistant materials.

Another significant type of nonwoven fabric is meltblown. The meltblown process involves extruding melted thermoplastic materials through fine nozzles, which results in extremely fine fibers that form a web structure. This type of nonwoven fabric is highly valued for its filtration properties, making it ideal for applications in the medical field, such as surgical masks and filtration systems.

Needle-punched nonwoven fabrics, on the other hand, are produced by mechanically interlocking fibers through a process that involves repeatedly piercing the web with needles. These fabrics are known for their softness and porosity, and are commonly used in automotive interiors, geotextiles, and insulation materials.

Beyond their packaging applications, nonwoven fabrics also play a vital role in numerous other industries. In the medical sector, they are utilized for creating disposable surgical gowns, drapes, and masks due to their hygiene and safety features. The automotive industry employs nonwoven fabrics for insulation, carpeting, and seat covers, thanks to their durability and cost-effectiveness. Moreover, in the textile industry, nonwoven fabrics serve as a base material for carpets, upholstery, and interlinings, demonstrating their versatility and multifunctionality.

Overall, nonwoven fabrics offer a unique combination of characteristics, including strength, durability, filtration capabilities, and adaptability to various manufacturing processes. These features make them an indispensable material across multiple industries, proving their value far beyond simply packaging solutions.

Eco-Friendly Advantages

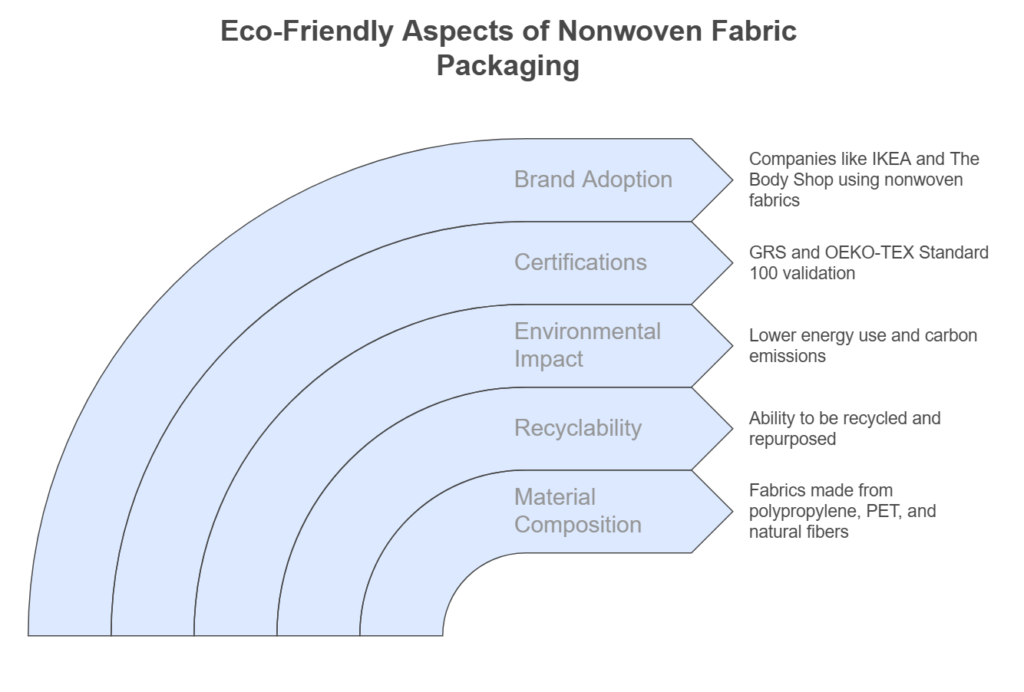

Nonwoven fabric packaging stands out for its eco-friendly attributes, which are increasingly important in today’s environmentally-conscious market. These materials are primarily composed of fibers derived from sources such as polypropylene, PET, and natural fibers such as cotton or bamboo. The key advantage lies in their recyclability. Nonwoven fabrics can often be recycled and repurposed, aligning perfectly with circular economy principles and reducing the strain on natural resources.

Moreover, nonwoven fabric packaging contributes significantly to minimizing environmental impact. These materials require less energy to produce compared to traditional woven fabrics, leading to lower carbon emissions. Their lightweight nature also means that transportation consumes less fuel, further reducing the overall carbon footprint.

Several certifications and standards validate the sustainability of nonwoven fabrics. The Global Recycled Standard (GRS) and the OEKO-TEX Standard 100 are among the eco-labels that identify nonwoven fabric packaging as a sustainable option. These certifications ensure that the production processes meet stringent environmental and health criteria, providing transparency and trust for consumers and businesses.

Many companies have successfully adopted eco-friendly nonwoven fabric packaging. For instance, IKEA uses nonwoven materials for some of its reusable shopping bags, reducing the need for single-use plastic. Similarly, brands like The Body Shop have transitioned to nonwoven fabric pouches for their gift sets, reinforcing their commitment to sustainability.

In summary, the eco-friendly advantages of nonwoven fabric packaging, from materials to recyclability and reduced environmental impact, make it an excellent choice for companies aiming to align with sustainable practices. The adoption by notable brands underscores the effectiveness and broad acceptance of nonwoven fabrics in reducing ecological footprints.

Cost-Effectiveness and Production

Nonwoven fabric packaging offers substantial cost benefits, making it an appealing choice for businesses aiming to optimize their budgets. One of the key advantages is its lower production cost. Nonwoven fabrics are often produced using high-speed manufacturing processes that require fewer resources compared to traditional materials like plastics, glass, or metals. These efficient processes not only reduce the material costs but also streamline production timelines, resulting in significant savings.

Another noteworthy benefit is the lightweight nature of nonwoven fabrics. This directly translates to lower shipping costs, as transportation fees are frequently determined by the weight of the shipment. Lighter packaging reduces fuel consumption during transit, further cutting down on logistical expenses. Consequently, businesses that switch to nonwoven fabric packaging can potentially experience a decrease in overall shipping costs, enhancing their profit margins.

When comparing nonwoven fabrics to conventional packaging materials, the cost advantages become even more evident. Traditional packaging materials can be expensive and entail higher production and shipping costs due to their weight and complexity. In contrast, nonwoven fabrics provide a more economical alternative without sacrificing quality or functionality. They offer excellent protection for a wide range of goods, from delicate items to heavy machinery, making them versatile and cost-effective for various industries.

Moreover, nonwoven fabric packaging not only offers direct financial savings but also adds value in terms of durability and environmental benefits, contributing to long-term cost-effectiveness. Businesses can benefit from reduced wastage, lower replacement costs, and improved sustainability credentials, which can enhance their market competitiveness. The cumulative cost advantages of nonwoven fabric packaging make it a strategic choice for companies looking to balance quality, affordability, and operational efficiency.

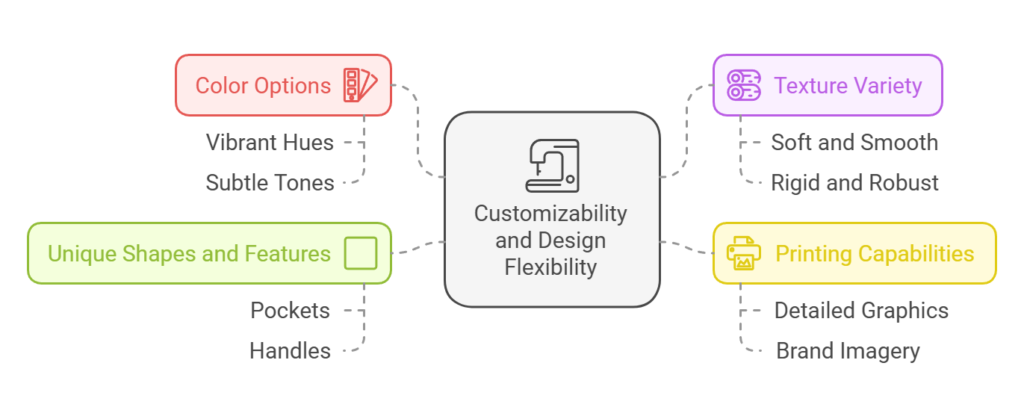

Customizability and Design

The customizability and design flexibility of nonwoven fabrics are significant advantages that set them apart from traditional packaging materials. Nonwoven fabrics can be tailored to meet the specific needs and preferences of different businesses, thus enhancing brand identity and consumer appeal. One of the most prominent features of nonwoven fabrics is their availability in a wide array of colors. Whether a brand desires vibrant hues that catch the eye or subtle tones that reflect a sophisticated aesthetic, nonwoven fabrics can be produced in virtually any color.

Beyond color customization, nonwoven fabrics offer a variety of textures. This allows companies to choose a texture that aligns with their brand image, whether it be soft and smooth for a luxurious feel, or more rigid and robust for a perception of durability. The tactile experience provided by the texture of nonwoven fabrics can significantly affect consumer perception and engagement.

Moreover, nonwoven fabrics stand out for their excellent printing capabilities. Advanced printing techniques enable detailed and high-quality graphics to be applied directly onto the fabric. This allows businesses to prominently display logos, slogans, and other brand-specific imagery, ensuring that their packaging stands out on shelves and is easily recognizable. For example, a company specializing in eco-friendly products might use nonwoven fabric packaging that features intricate, nature-inspired designs and earthy tones, reinforcing their brand’s commitment to sustainability.

The opportunities for customization in nonwoven fabric packaging are vast. Businesses can incorporate not only colors, textures, and prints but also unique shapes and functional features such as pockets or handles. These design elements not only improve the user experience but also serve as memorable brand touchpoints. Customizable nonwoven fabric packaging thus helps brands to create a distinct and cohesive identity that resonates with their target audience.

Applications of Nonwoven Fabric Packaging

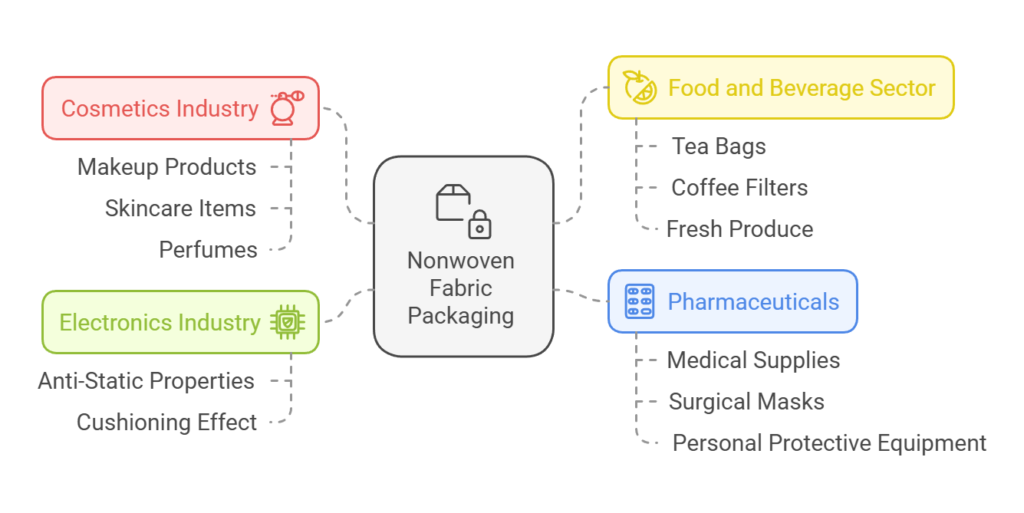

Nonwoven fabric packaging boasts a diverse array of applications across various industries due to its unique properties such as durability, product protection, and superior presentation. One of the significant sectors benefiting from nonwoven fabric packaging is the cosmetics industry. The use of this material provides high-quality, breathable packages that maintain the integrity of delicate makeup products, skincare items, and perfumes. Its soft texture and customizable designs ensure that products are not only protected but also stand out on retail shelves.

In the electronics industry, nonwoven fabric packaging plays a crucial role in protecting sensitive devices during transportation and storage. Its anti-static properties safeguard electronic components from electrostatic discharge, which can cause significant damage. Moreover, the cushioning effect of nonwoven fabric helps prevent mechanical shocks and vibrations, ensuring that gadgets such as mobile phones, laptops, and tablets remain in perfect condition.

The food and beverage sector also greatly benefits from nonwoven fabric packaging. Its excellent moisture resistance preserves the freshness and extends the shelf life of perishable items. Nonwoven fabric is often used for tea bags, coffee filters, and packaging for fresh produce, ensuring that consumables remain hygienic and uncontaminated. Additionally, these packages can be easily customized to fit branding needs, enhancing product visibility in retail environments.

Pharmaceuticals demand high standards of hygiene and safety in packaging, making nonwoven fabric an ideal choice. It offers a sterile, durable solution for packaging medical supplies, surgical masks, and personal protective equipment (PPE). The breathable nature of nonwoven fabric prevents the buildup of humidity and bacteria, thereby maintaining the efficacy of medications and health products. Furthermore, the ability to produce tamper-evident seals is crucial for preserving the integrity and security of pharmaceutical products.

Overall, the versatility of nonwoven fabric packaging across various industries showcases its capability to meet diverse requirements. Its durability, protective qualities, and aesthetic appeal make it a superior choice for manufacturers seeking reliable and innovative packaging solutions.

Challenges and Considerations

While nonwoven fabric packaging offers numerous benefits, it is crucial to acknowledge and address certain challenges and considerations that come with its use. One of the primary concerns is limited transparency. Unlike plastic or glass, nonwoven fabrics are generally opaque, thus impeding the consumer’s ability to view the product inside. This can be particularly challenging in industries where product visibility is crucial, such as food packaging. To mitigate this issue, manufacturers can incorporate clear windows or use semi-transparent nonwoven materials for specific applications.

Variations in quality also pose significant challenges. Nonwoven fabrics can vary widely in terms of strength, durability, and finish, depending on the material composition and manufacturing processes used. Such inconsistencies can affect the performance and reliability of the packaging. To address these concerns, it is advisable to source materials from reputable suppliers who maintain strict quality control standards. Additionally, conducting thorough quality assurance tests can help in identifying and rectifying potential issues before they escalate.

Another vital consideration is the biodegradability of nonwoven fabric. Although these fabrics are often marketed as eco-friendly alternatives to traditional plastics, not all nonwoven materials are biodegradable. The primary factor determining biodegradability is the fiber composition, with natural fibers like cotton and jute being more environmentally friendly than synthetic fibers. To ensure sustainable practices, companies should prioritize using nonwoven fabrics made from biodegradable or compostable materials. Furthermore, clear labeling and certifications from credible environmental organizations can aid consumers in making informed decisions.

Lastly, the cost factor cannot be ignored. High-quality nonwoven fabrics can be more expensive than conventional packaging materials. While the upfront cost may be higher, it’s essential to consider the long-term environmental and operational benefits, such as enhanced brand reputation and reduced waste management expenses. By adopting a holistic approach, companies can make well-informed choices that balance cost with sustainability and performance.

Frequently Asked Questions (FAQs)

How are nonwoven fabrics made?

Nonwoven fabrics are produced through a process that bonds fibers together without weaving or knitting. This is typically achieved by using chemical, mechanical, or thermal methods to bind the fibers. The most common production methods include spunbonding, meltblowing, and needlepunching. These processes create a fabric with a web-like structure, offering unique properties suitable for various applications, including packaging.

Can nonwoven fabrics be recycled?

Yes, nonwoven fabrics can be recycled. The recyclability largely depends on the type of fibers used and the presence of any additives or coatings. Many nonwoven fabrics, especially those made from polypropylene, are recyclable and can be processed to produce new items. It is essential to follow local recycling guidelines and practices to ensure that nonwoven materials are properly recycled.

What are the environmental benefits of nonwoven packaging?

Nonwoven packaging offers several environmental benefits. Firstly, it is often more energy-efficient to produce compared to traditional woven fabrics. Additionally, nonwoven materials can be made from recycled fibers, reducing the waste going to landfills. Many nonwoven fabrics are also biodegradable or compostable, further minimizing their environmental footprint. By opting for nonwoven packaging, companies can contribute to sustainable practices and decrease their overall environmental impact.

How durable is nonwoven fabric packaging?

Nonwoven fabric packaging is known for its durability and strength. The manufacturing process allows for the creation of robust fabrics that can withstand considerable wear and tear. Nonwoven materials are resistant to punctures and tears, making them ideal for various packaging applications. Moreover, they can be designed to be water-resistant, UV-resistant, and able to maintain their integrity under different environmental conditions, ensuring that the packaged goods remain protected.

16 Responses

I loved as much as you will receive carried out right here The sketch is attractive your authored material stylish nonetheless you command get got an impatience over that you wish be delivering the following unwell unquestionably come more formerly again since exactly the same nearly a lot often inside case you shield this hike

Thanks for your comment! We’ll keep working hard to provide better content. 😊

Insanont Nice post. I learn something totally new and challenging on websites

Thanks! Glad you found it useful.

I have been browsing online more than three hours today yet I never found any interesting article like yours It is pretty worth enough for me In my view if all website owners and bloggers made good content as you did the internet will be a lot more useful than ever before

Thanks for your kind words! Glad you liked the article. 😊

Blue Techker This was beautiful Admin. Thank you for your reflections.

Thank you! Glad you liked it.

Strands Hint I am truly thankful to the owner of this web site who has shared this fantastic piece of writing at at this place.

Thanks for your kind words! Glad you liked the article. 😊

Noodlemagazine This was beautiful Admin. Thank you for your reflections.

Thank you! We hope to share more content that touches you in the future. Any suggestions?

Your article helped me a lot, is there any more related content? Thanks!

Glad it helped! More related content will be updated soon. Stay tuned!

hentairead Hi there to all, for the reason that I am genuinely keen of reading this website’s post to be updated on a regular basis. It carries pleasant stuff.

Appreciate your feedback. We’ll consider exploring different angles in future posts.