Introduction

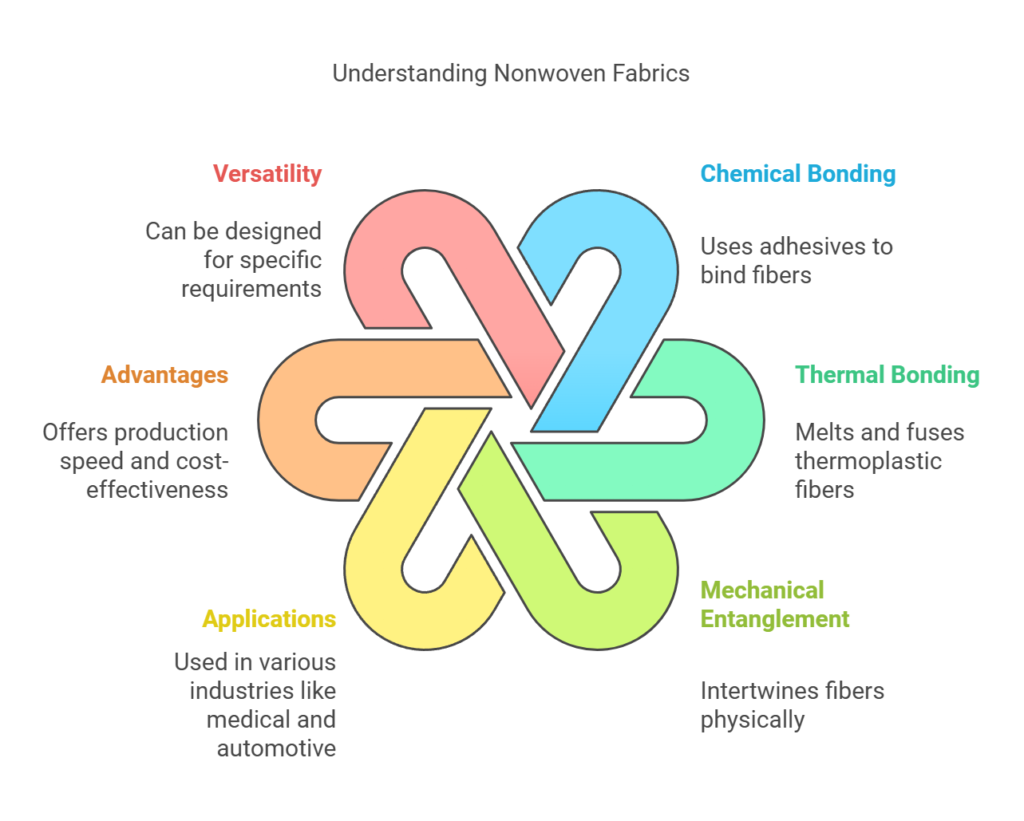

In recent years, nonwoven fabric products have garnered considerable attention across various industries, primarily due to their exceptional versatility and cost-efficiency. Unlike traditional fabrics that rely on weaving or knitting techniques, nonwoven fabrics are created through alternative methods. These processes may involve chemical bonding, thermal bonding, or mechanical entanglement to unite fibers into a cohesive fabric.

The diverse range of applications for nonwoven fabrics attests to their indispensability in modern manufacturing and daily life. Medical supplies, for instance, heavily depend on nonwoven materials to produce items such as surgical gowns, masks, and sanitary products. These fabrics are valued for their superior filtration capabilities, breathability, and softness, which are critical for healthcare purposes.

Similarly, in the automotive industry, nonwoven fabrics are incorporated into numerous components. Their lightweight yet durable nature makes them ideal for enhancing vehicle performance and efficiency. Furthermore, nonwoven materials are instrumental in producing insulation, carpeting, and upholstery, which contribute to the overall comfort and functionality of automobiles.

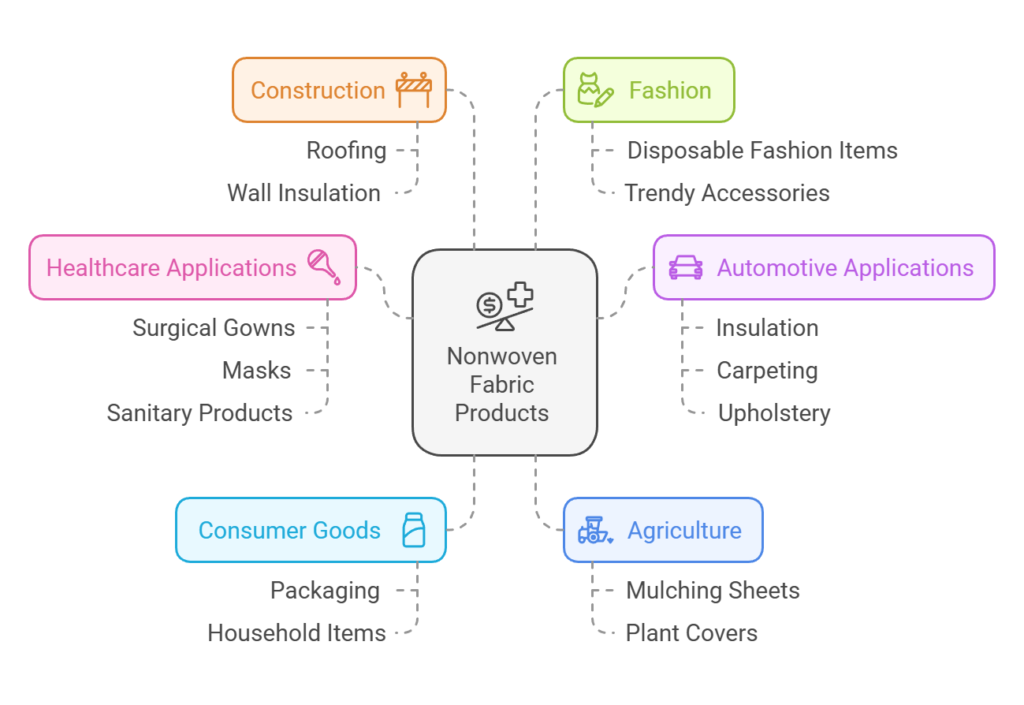

The reach of nonwoven fabric products extends beyond healthcare and automotive sectors. They play a pivotal role in consumer goods, agriculture, construction, and even fashion. The inherent advantages, such as high strength, absorbency, and the ability to be customized, have solidified their position as essential materials in diverse production environments.

As industries continue to evolve and demand innovative materials, nonwoven fabrics are likely to become even more pervasive. Understanding the mechanisms behind their production and application can provide valuable insights into why these products are indispensable in modern manufacturing processes and everyday use.

What Are Nonwoven Fabrics?

Nonwoven fabrics are a category of materials produced by bonding fibers together through methods that do not involve traditional weaving or knitting. These unique fabrics are created using various techniques such as chemical bonding, thermal bonding, or mechanical entanglement. By bypassing the need for yarn formation, nonwoven fabrics offer distinct advantages in terms of production speed and cost-effectiveness.

Chemical bonding involves the use of adhesives to bind the fibers together, creating a cohesive fabric structure. Thermal bonding, on the other hand, utilizes heat to melt and fuse thermoplastic fibers, which solidify upon cooling to form a durable fabric. Mechanical entanglement, a method that includes techniques like needlepunching or hydroentangling, physically intertwines the fibers to achieve a strong interconnected network.

One of the primary attributes of nonwoven fabrics is their lightweight nature coupled with significant strength. These characteristics make them highly desirable across a broad spectrum of industries. For instance, in the medical sector, nonwoven fabrics are used to manufacture surgical gowns, masks, and sterilization wraps due to their ability to provide effective barriers against contaminants. In the automotive industry, they are utilized for interior materials, filtration media, and insulation components.

Additionally, the versatility of nonwoven fabrics is noteworthy. They can be designed to meet specific requirements such as breathability, water resistance, or flame retardancy, hence expanding their potential applications. Nonwoven fabrics also find their use in everyday items like wipes, diapers, and home furnishings due to their convenience and functional properties.

Overall, the innovative manufacturing processes and the wide-ranging applications make nonwoven fabrics indispensable in modern technology and everyday life. Their adaptability opens new avenues for development and usage, continually driving advancements across various sectors.

Key Applications of Nonwoven Fabrics

Nonwoven fabrics have become an essential element in various industries due to their versatility, affordability, and efficiency. In the medical sector, these materials are frequently used to manufacture critical supplies such as surgical gowns, masks, and drapes. The disposable nature of nonwoven fabrics ensures high hygiene standards, preventing cross-contamination and infection, which is crucial in healthcare environments.

In the realm of personal hygiene, nonwoven fabrics are integral to the production of items like diapers, sanitary napkins, and adult incontinence products. Their soft texture ensures comfort, while their absorbent properties provide the necessary functionality. The material’s lightweight and breathable features make it ideal for products that require frequent, convenient use without sacrificing user comfort.

The automotive industry also benefits significantly from nonwoven fabrics, using them in various components, including filters, soundproofing, and insulating materials. These fabrics help improve vehicle performance by enhancing air quality within the cabin and reducing noise levels, contributing to a more comfortable driving experience.

For household applications, nonwoven fabrics serve as a staple in everyday cleaning and maintenance tasks. Products such as cleaning wipes, dusters, and reusable cloths leveraged from nonwoven materials offer superior cleaning capabilities. Additionally, upholstery and home furnishings often incorporate these fabrics due to their durability and ease of maintenance.

The widespread use of nonwoven fabrics across these diverse applications underscores their adaptability and effectiveness. Their unique properties allow them to meet stringent requirements in various environments, making them indispensable in both specialized and everyday contexts. As innovation continues, the role of nonwoven fabrics is likely to expand, further cementing their place in modern industry and daily life.

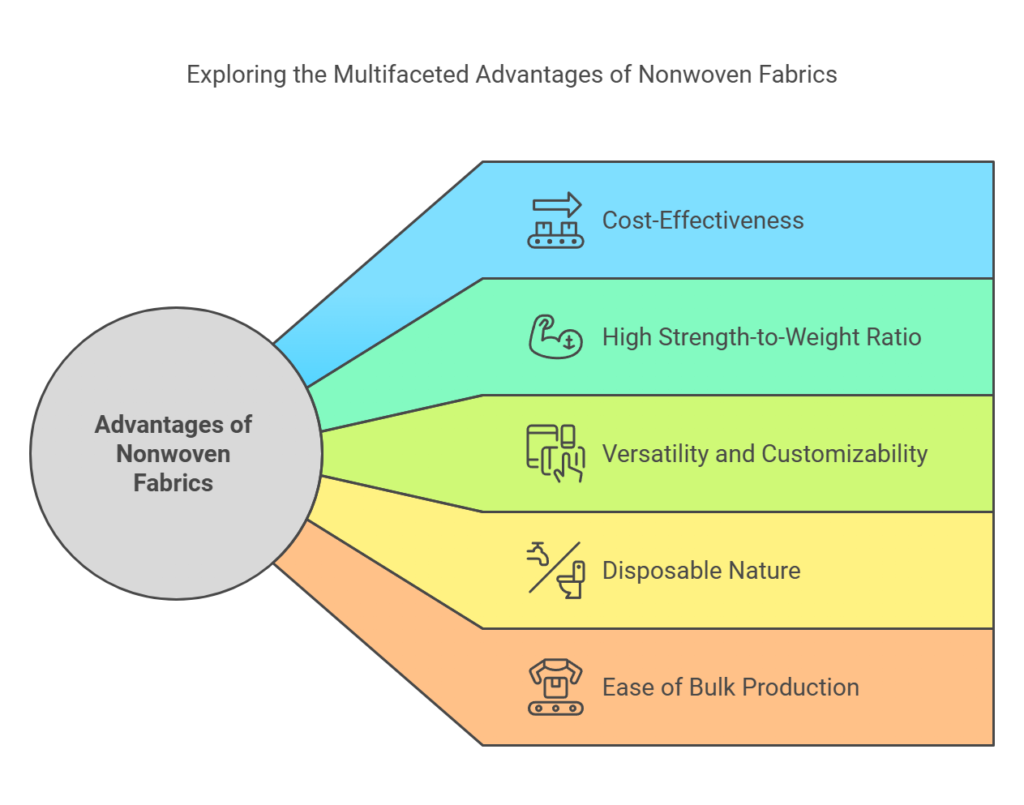

Advantages of Nonwoven Fabrics

Nonwoven fabrics present numerous advantages over traditional woven and knitted fabrics, making them a versatile and invaluable choice across various industries. One of the most notable benefits is their cost-effectiveness. The production process of nonwoven fabrics is typically less labor-intensive and faster, resulting in lower manufacturing costs. This enables the bulk production of nonwoven materials at an economical price point.

Moreover, nonwoven fabrics boast a remarkable high strength-to-weight ratio. This means they can provide substantial strength and durability while remaining lightweight, a feature particularly advantageous in applications where material efficiency and performance are critical.

Another key advantage is the versatility and customizability of nonwoven fabrics. They can be engineered to exhibit specific properties tailored to the needs of different applications. For instance, they can be made breathable or impermeable, making them ideal for items like medical gowns and protective clothing. They can also be designed to enhance absorbency for products such as diapers and sanitary napkins, or to offer flame resistance for use in transportation and construction sectors.

Nonwoven fabrics are also distinguished by their disposable nature, providing a hygienic solution especially beneficial for the healthcare and hygiene industries. Products like surgical masks, disposable wipes, and single-use gowns underscore the critical role of nonwoven materials in promoting health and safety.

Additionally, the ease of producing nonwoven fabrics in bulk plays a pivotal role in meeting high demand efficiently. These materials can be quickly and readily manufactured on a massive scale, ensuring a consistent supply for critical industries.

Overall, the unique properties and advantages of nonwoven fabrics position them as a superior choice for a diverse range of applications, significantly contributing to their growing utilization worldwide.

Manufacturing Processes for Nonwoven Fabrics

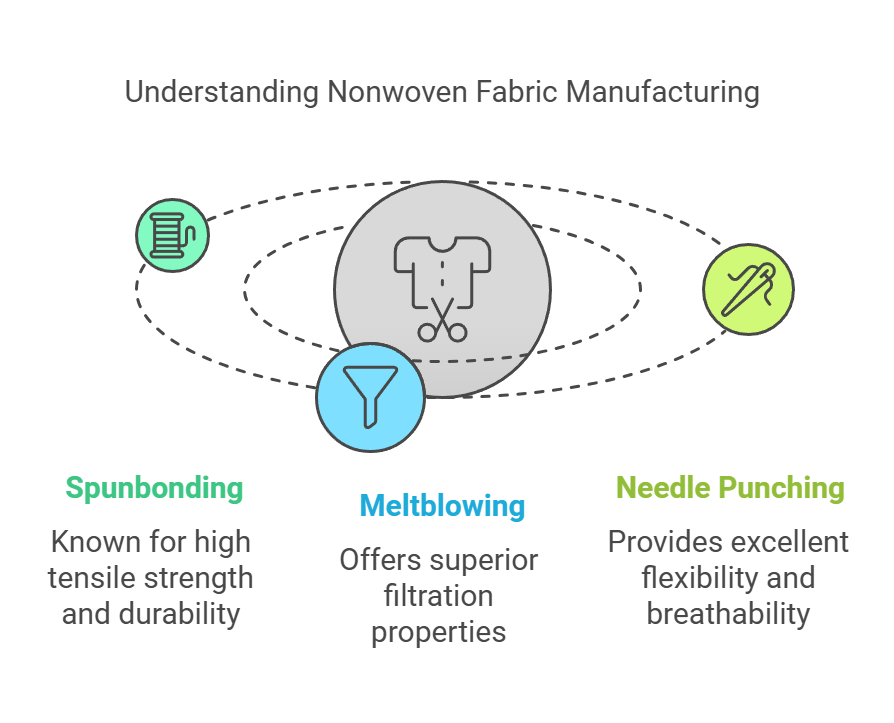

Nonwoven fabrics are produced through various manufacturing processes, each offering unique attributes to the resulting fabric. Among these methods, three commonly employed techniques stand out: spunbonding, meltblowing, and needle punching. Understanding these processes provides insight into the diverse characteristics nonwoven fabrics can exhibit.

Spunbonding is a widely used method in which thermoplastic polymers, such as polypropylene, are extruded into continuous filaments. These filaments are then laid randomly onto a conveyor and bonded thermally to form a fabric. The resultant spunbonded nonwoven fabrics are renowned for their high tensile strength, durability, and resistance to tearing. Their applications span across numerous industries, including construction, agriculture, and medical sectors.

Another critical technique is meltblowing. This process also begins with the extrusion of thermoplastic polymers, but the filaments produced are much finer due to a high-speed gas stream that rapidly cools and attenuates them. The resultant web of microfibers is laid onto a collection surface and bonded thermally. Meltblown nonwoven fabrics are praised for their superior filtration properties, making them ideal for applications such as surgical masks, air and liquid filter media, and insulation materials. The fineness of the fibers enhances the fabric’s ability to capture particles, including bacteria and allergens, which is crucial in medical and hygienic products.

Needle punching is a mechanical process where fiber webs are entangled using barbed needles. As the needles penetrate and withdraw from the web, fibers are interlocked, creating a coherent fabric without the need for adhesives or thermal bonding. Needle punched nonwoven fabrics offer excellent flexibility, high permeability, and breathability. These attributes render them suitable for applications in geotextiles, automotive interiors, and felt products.

Each manufacturing process for nonwoven fabric lends itself to fabricating materials with specific properties tailored to different end-uses. Whether it is the strength and durability of spunbonded fabrics, the efficient filtration of meltblown fabrics, or the flexibility of needle punched fabrics, the manufacturing techniques play an essential role in determining the performance and suitability of nonwoven fabric products.

Challenges in Nonwoven Fabric Production

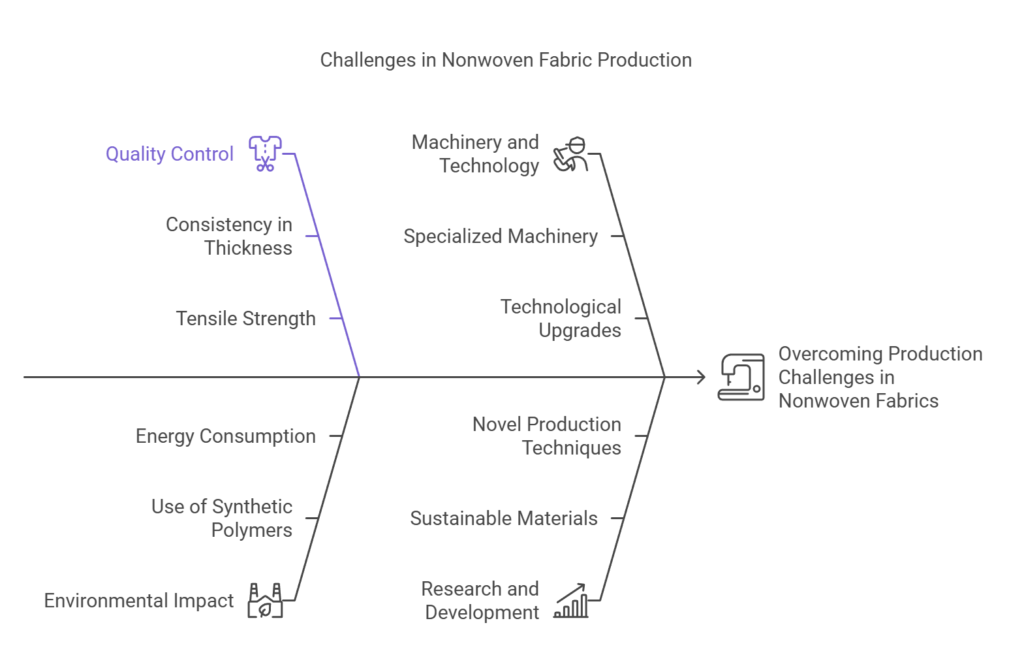

Despite the numerous advantages that nonwoven fabrics offer, their production is fraught with several challenges that manufacturers must navigate. One primary issue lies in quality control. Nonwoven fabric production demands stringent monitoring to ensure consistency in thickness, tensile strength, and other critical properties. Variations in these parameters can significantly impact the fabric’s performance and usability. Implementing rigorous quality control systems and utilizing advanced testing equipment are essential to mitigate these concerns.

Another notable challenge is the environmental impact associated with nonwoven fabric production. The manufacturing processes often involve the use of synthetic polymers, chemicals, and significant energy consumption, which collectively contribute to environmental degradation. Addressing these environmental concerns necessitates substantial investment in sustainable practices and the adoption of eco-friendly materials. Innovations in recycling processes and the utilization of biodegradable fibers are steps toward reducing the ecological footprint of nonwoven fabrics.

Furthermore, the production of nonwoven fabrics demands specialized machinery and technology. The precision required in processes like bonding, spinning, and layering necessitates high-tech equipment capable of adhering to strict specifications. This requirement for specialized machinery translates to considerable capital investment and the need for continuous technological upgrades. Technological advancements, such as automation and AI-driven quality assurance systems, are becoming increasingly critical in enhancing production efficiency and maintaining competitive advantage in the market.

The journey to overcoming these challenges is ongoing and relies heavily on research and development. Manufacturers and researchers must collaborate to explore novel production techniques, develop sustainable materials, and implement cutting-edge technologies. By prioritizing innovation and sustainability, the nonwoven fabric industry can position itself to meet the evolving demands of various sectors while addressing the inherent production challenges.

Future Trends in Nonwoven Fabrics

The nonwoven fabric industry stands on the brink of significant evolution, bolstered by continuous advancements in both materials science and manufacturing technology. One of the most promising trends is the rise of biodegradable nonwovens. As sustainability takes center stage, manufacturers are increasingly focusing on eco-friendly alternatives. Biodegradable nonwovens, developed from natural fibers like cotton, jute, and bamboo, offer an environmentally responsible solution. Their ability to decompose naturally reduces the impact on landfills, aligning with global efforts to mitigate environmental damage.

Moreover, enhanced filtration capabilities are set to redefine how we utilize nonwoven fabrics, particularly in healthcare and environmental applications. Improved filtration efficiency is being achieved through innovative techniques such as electrospinning and nanotechnology, enabling the development of nonwovens capable of capturing even the minutest particles. This advancement is particularly crucial in the creation of high-efficiency particulate air (HEPA) filters and personal protective equipment (PPE), which play a pivotal role in safeguarding human health.

Another groundbreaking trend in the nonwoven fabrics sector is the integration of smart technologies. Smart nonwoven fabrics, embedded with sensors and conductive materials, are paving the way for a new era of intelligent textiles. These fabrics can monitor physiological conditions, detect environmental changes, or even provide therapeutic benefits. The potential applications span from healthcare and sports to fashion and home automation, heralding a future where nonwoven fabrics offer both utility and data-driven insights.

As these innovations continue to unfold, it is evident that nonwoven fabrics will become increasingly indispensable in various industries. The amalgamation of sustainability, advanced filtration, and smart technology positions nonwoven fabrics at the forefront of material science innovation, promising a future where their applications are both diverse and essential to improving our daily lives.

FAQs about Nonwoven Fabric Products

Nonwoven fabrics stand distinct from woven fabrics in their method of production. Unlike woven fabrics, which are made by interlacing threads in a specific pattern, nonwoven fabrics are produced by bonding or interlocking fibers through mechanical, chemical, or thermal processes. This results in a unique structure and texture, contributing to their diverse applications in various industries such as healthcare, automotive, and consumer goods.

Regarding the environmental impact, nonwoven fabrics can vary in their ecological footprint. While some nonwoven materials are derived from synthetic fibers, which can be problematic for the environment due to their persistence and potential release of microplastics, there are also biodegradable and eco-friendly nonwoven options. These environmentally friendly variants are made from renewable resources and are designed to break down more easily in natural settings.

The recyclability of nonwoven fabrics depends on the materials used in their production. Nonwoven fabrics made from recyclable polymers, such as polypropylene, can be reprocessed and reused in the manufacturing of new products. However, the recycling process for nonwovens can be more complex compared to traditional woven textiles due to the varied bonding methods and combination of different fiber types. Advances in recycling technology and increased emphasis on sustainable practices are gradually improving the recyclability of nonwoven fabrics.

The durability of nonwoven fabric products can vary widely based on their intended use and materials. Nonwoven fabrics can be engineered to be very strong and long-lasting or designed for single-use applications. For instance, nonwoven fabrics used in medical disposable products such as masks and surgical gowns are meant for short-term use, while geotextiles and automotive interiors made from more robust nonwoven materials are designed for prolonged durability.

4 Responses

Usually I do not read article on blogs however I would like to say that this writeup very compelled me to take a look at and do it Your writing style has been amazed me Thank you very nice article

Thanks for your compliment! Glad you liked the article. 😊

Mitolyn very informative articles or reviews at this time.

Glad it was useful! We’ll be adding more related content soon. Stay tuned.